Walnut shelling device

A walnut and extrusion board technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of injury caused by fixtures, time-consuming and laborious, broken nuts, etc., to save manpower and material resources, high efficiency, and efficient removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

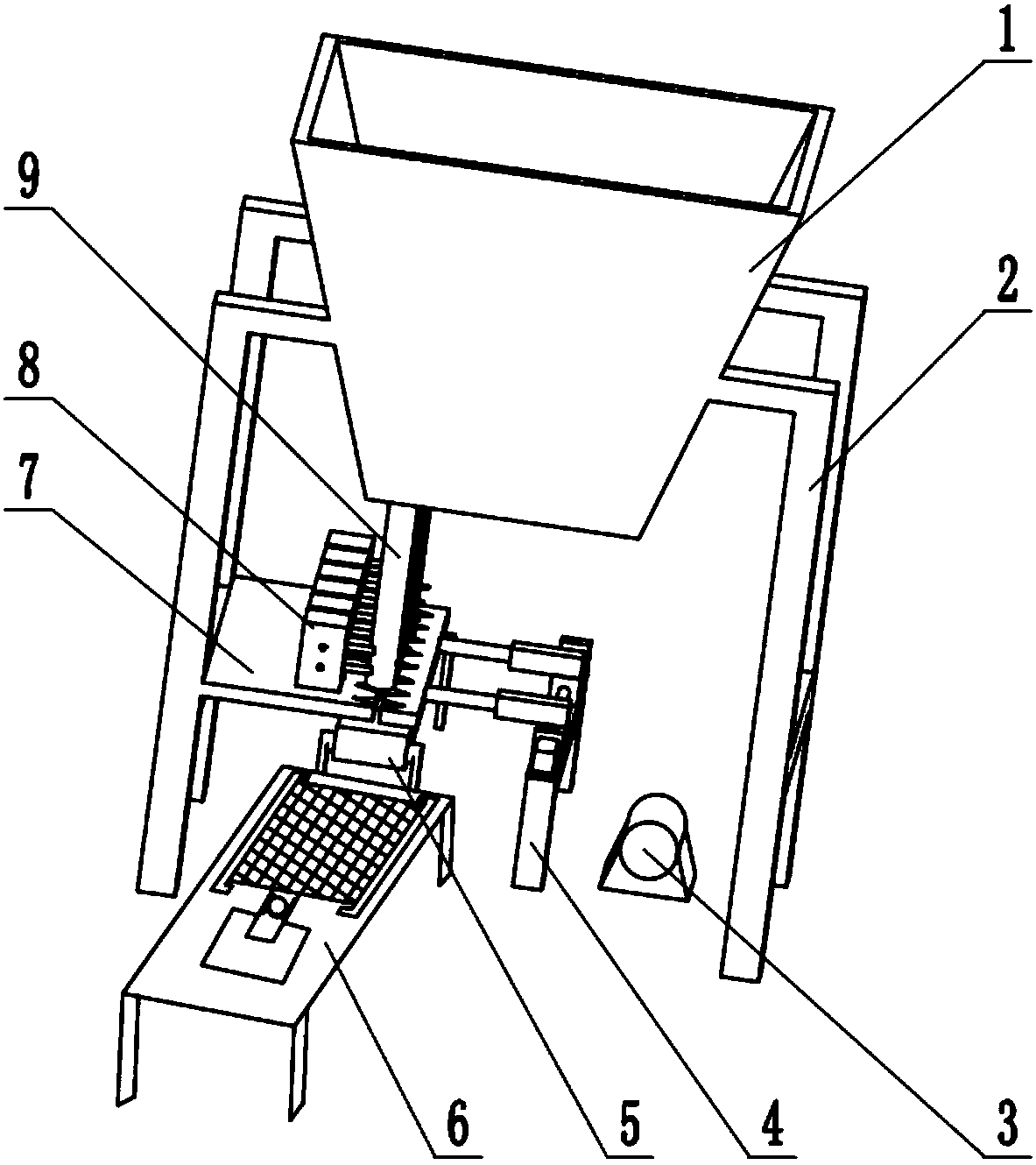

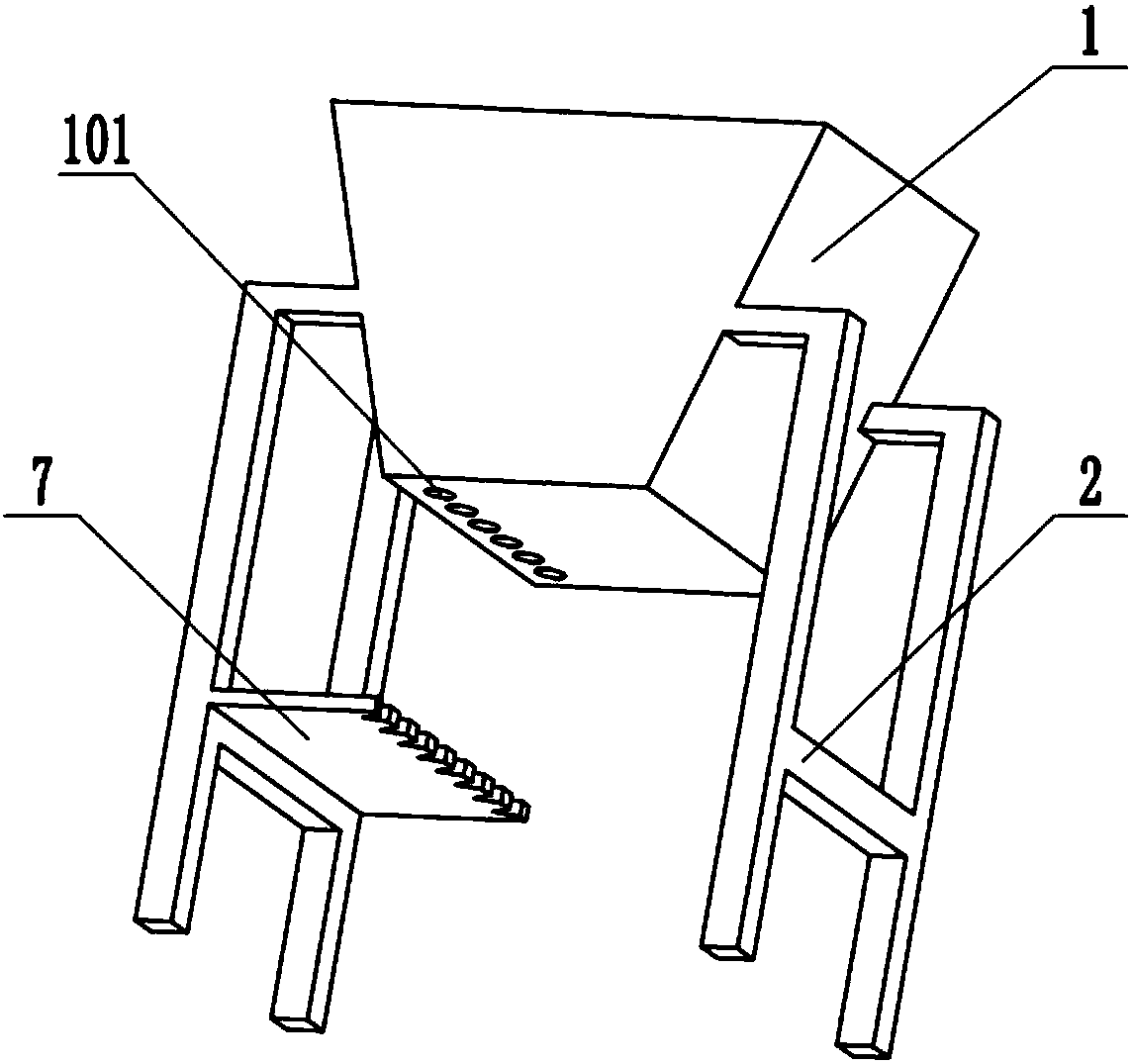

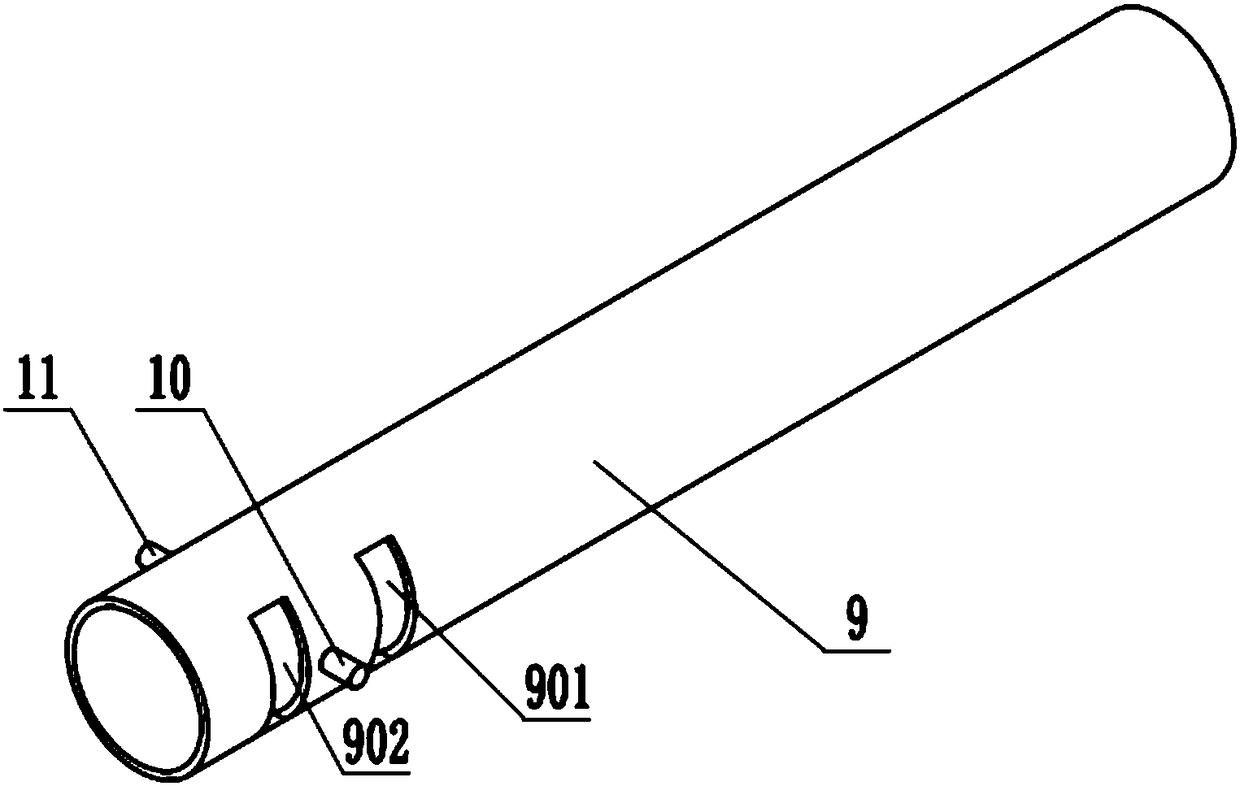

[0019] A walnut shelling device is composed of a feeding trough 1, a frame 2, an air pump 3, an extrusion mechanism 4, a conveyor belt 5, a screening mechanism 6, a fixed extrusion plate 7, a small cylinder 8, a feeding pipe 9, a photoelectric Composed of a switch receiver 10, a photoelectric switch transmitter 11 and a controller, the cutting trough 1 is welded on the top of the frame 2, and the bottom of the cutting chute 1 is provided with a drop hole 101, and the drop hole 101 and the drop tube 9 connection, the lower part of the drop tube 9 is opened with an upper extension arm hole 901 and a lower extension arm hole 902 downwards, and a photoelectric switch receiver 10 is provided on the left side of the upper part of the lower extension arm hole 902, and a photoelectric switch receiver 10 is arranged on the right side. A photoelectric switch transmitter 11 is provided, and a fixed extruding plate 7 is provided on one side of the bottom of the frame 2, and the front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com