Intermittent-feeding juicing apparatus used for hawthorn fruit deep-processing

A technology of deep processing and feeding, applied in application, juice extraction, food science, etc., can solve the problems of wasting hawthorn raw materials and not being able to fully squeeze, and achieve the effect of speeding up and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

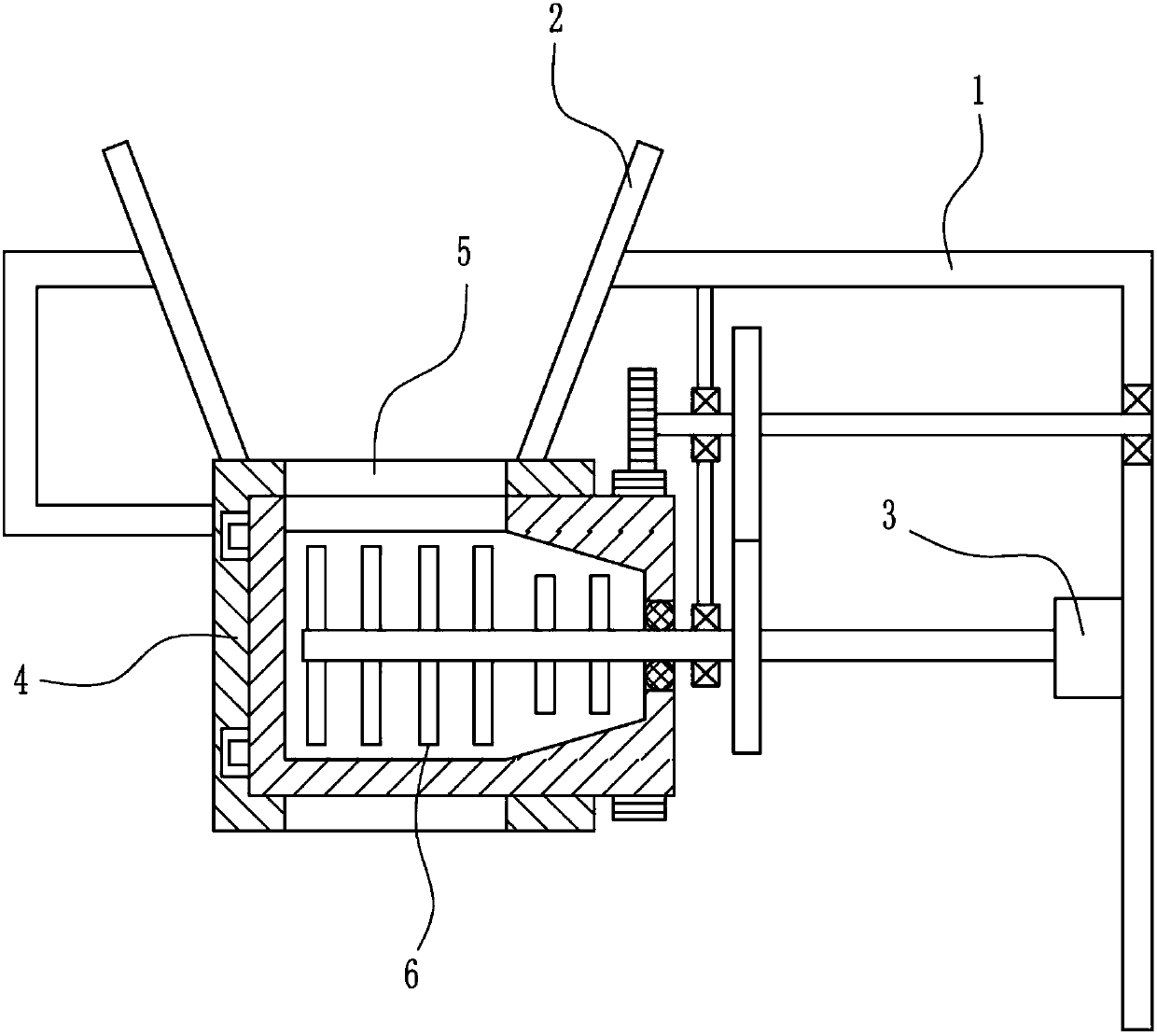

[0035] A kind of hawthorn deep processing is used the intermittent feeding juicing device, as Figure 1-8 As shown, it includes a bracket 1, a feeding hopper 2, a driving mechanism 3, a placement bucket 4 and a crushing mechanism 6, the inner wall of the bracket 1 is connected with a driving mechanism 3, the top left side of the bracket 1 is connected with a feeding hopper 2, and the bracket 1 The left end of the bucket 4 is connected with a bucket 4, the top of the bucket 4 is connected with the top of the feed hopper 2, the upper and lower sides of the bucket 4 are provided with a first through hole 5, the bucket 4 is connected with a crushing mechanism 6, and the crushing mechanism 6 is connected with drive mechanism 3.

Embodiment 2

[0037] A kind of hawthorn deep processing is used the intermittent feeding juicing device, as Figure 1-8 As shown, it includes a bracket 1, a feeding hopper 2, a driving mechanism 3, a placement bucket 4 and a crushing mechanism 6, the inner wall of the bracket 1 is connected with a driving mechanism 3, the top left side of the bracket 1 is connected with a feeding hopper 2, and the bracket 1 The left end of the bucket 4 is connected with a bucket 4, the top of the bucket 4 is connected with the top of the feed hopper 2, the upper and lower sides of the bucket 4 are provided with a first through hole 5, the bucket 4 is connected with a crushing mechanism 6, and the crushing mechanism 6 is connected with drive mechanism 3.

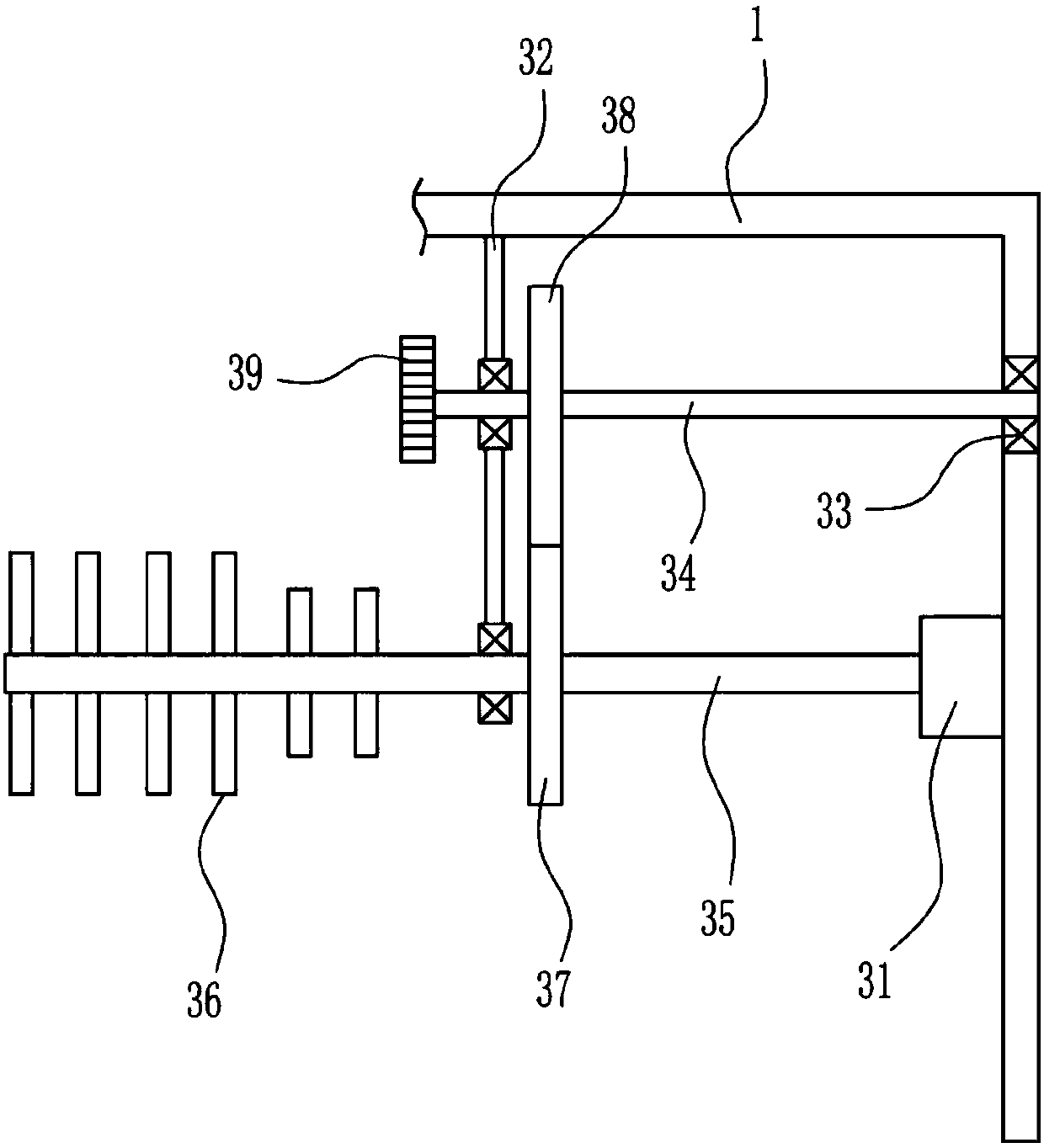

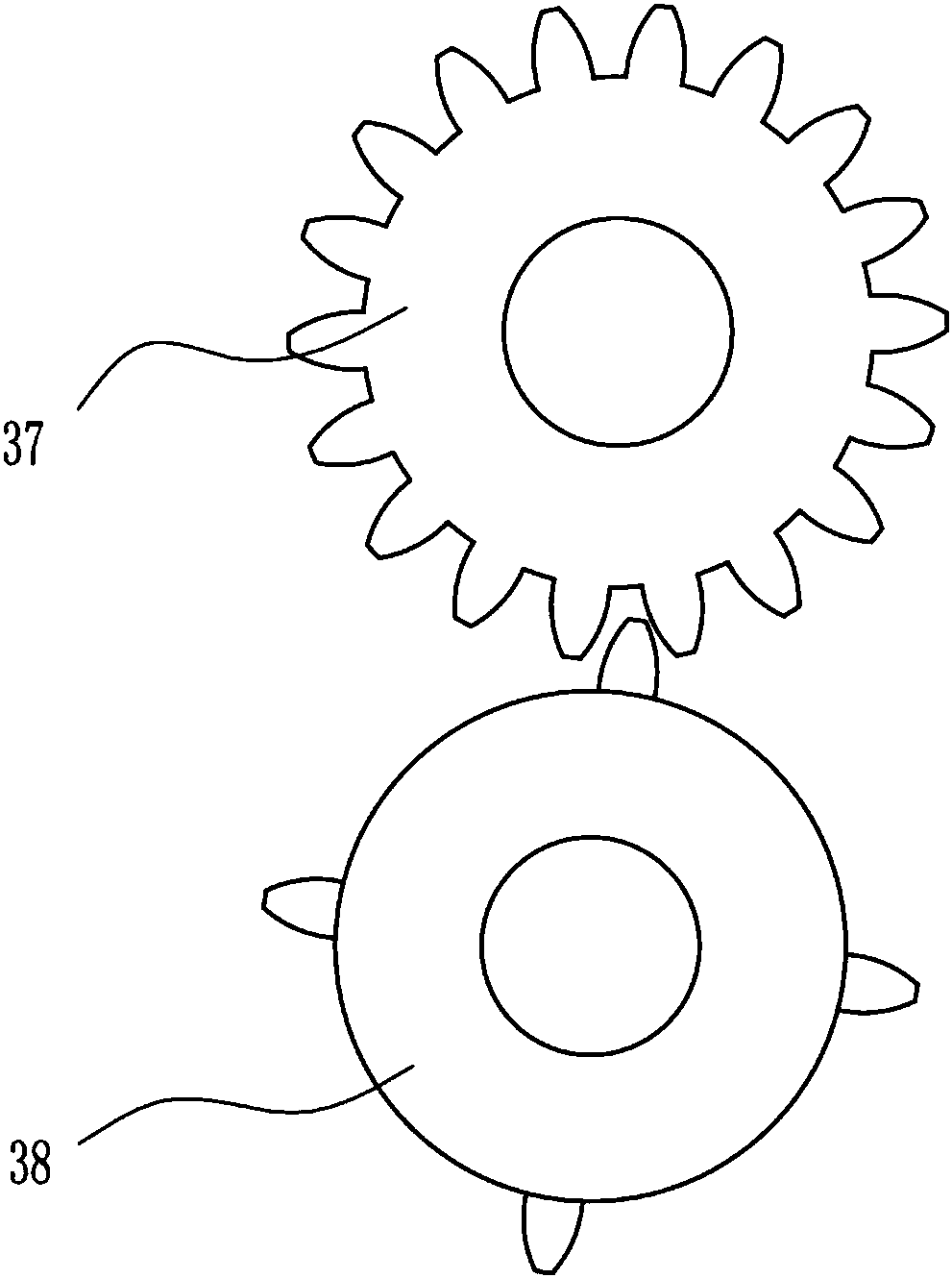

[0038] The driving mechanism 3 includes a motor 31, a pole 32, a first bearing seat 33, a first rotating rod 34, a second rotating rod 35, a crushing rod 36, a first gear 37, a missing gear 38 and a second gear 39, and the support 1 The right side of the ...

Embodiment 3

[0040] A kind of hawthorn deep processing is used the intermittent feeding juicing device, as Figure 1-8 As shown, it includes a bracket 1, a feeding hopper 2, a driving mechanism 3, a placement bucket 4 and a crushing mechanism 6, the inner wall of the bracket 1 is connected with a driving mechanism 3, the top left side of the bracket 1 is connected with a feeding hopper 2, and the bracket 1 The left end of the bucket 4 is connected with a bucket 4, the top of the bucket 4 is connected with the top of the feed hopper 2, the upper and lower sides of the bucket 4 are provided with a first through hole 5, the bucket 4 is connected with a crushing mechanism 6, and the crushing mechanism 6 is connected with drive mechanism 3.

[0041] The driving mechanism 3 includes a motor 31, a pole 32, a first bearing seat 33, a first rotating rod 34, a second rotating rod 35, a crushing rod 36, a first gear 37, a missing gear 38 and a second gear 39, and the support 1 The right side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com