High-strength high-toughness anti-corrosion aluminum alloy for rail traffic and extrusion method of high-strength high-toughness anti-corrosion aluminum alloy

A technology of rail transit and extrusion method, which is applied in the field of high-strength, toughness and corrosion-resistant aluminum alloy and its extrusion, which can solve the problems of inability to obtain complete fibrous crystal structure, impact fracture toughness and stress corrosion resistance performance limitations, and achieve excellent anti-corrosion properties. Impact fracture toughness and stress corrosion resistance, the effect of improving impact fracture toughness and stress corrosion resistance, high-strength impact fracture toughness and stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

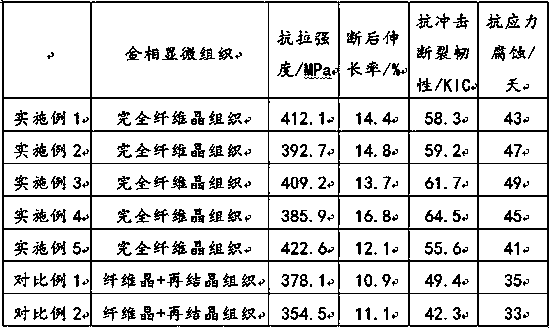

[0056] The high-strength, toughness and anti-corrosion aluminum alloy for rail transit is composed of the following components in mass percentage: Zn 4.6%, Mg 1.8%, Cu 0.2%, Mn 0.2%, Cr 0.1%, Zr 0.1%, Ti 0.01%, B 0.002%, Fe≤0.15%, Si≤0.1%, the balance is Al and other unavoidable impurities, the individual content of other unavoidable impurities is ≤0.05%, and the total amount is ≤0.15%.

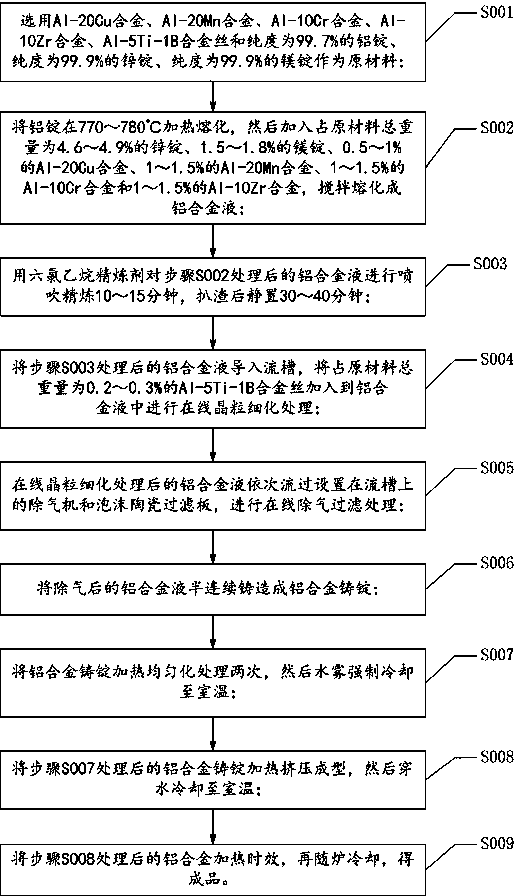

[0057] The extrusion method of the aluminum alloy comprises the following steps:

[0058] The first step: select Al-20Cu alloy, Al-20Mn alloy, Al-10Cr alloy, Al-10Zr alloy, Al-5Ti-1B alloy wire and aluminum ingots with a purity of 99.7%, zinc ingots with a purity of 99.9%, and purity 99.9% magnesium ingots are used as raw materials;

[0059] Step 2: Heat and melt the aluminum ingot at 770°C, then add 4.6% zinc ingot, 1.8% magnesium ingot, 1% Al-20Cu alloy, 1% Al-20Mn alloy, 1% Al-10Cr alloy and 1% Al-10Zr alloy are stirred and melted into aluminum alloy liquid;

[0060] The third step: use...

Embodiment 2

[0068]The high-strength, toughness and anti-corrosion aluminum alloy for rail transit is composed of the following components by mass percentage: Zn 4.8%, Mg 1.6%, Cu 0.15%, Mn 0.25%, Cr 0.125%, Zr 0.125%, Ti 0.015%, B 0.003%, Fe≤0.15%, Si≤0.1%, the balance is Al and other unavoidable impurities, the individual content of other unavoidable impurities is ≤0.05%, and the total amount is ≤0.15%.

[0069] The extrusion method of the aluminum alloy comprises the following steps:

[0070] The first step: select Al-20Cu alloy, Al-20Mn alloy, Al-10Cr alloy, Al-10Zr alloy, Al-5Ti-1B alloy wire and aluminum ingots with a purity of 99.7%, zinc ingots with a purity of 99.9%, and purity 99.9% magnesium ingots are used as raw materials;

[0071] Step 2: Heat and melt the aluminum ingot at 775°C, then add 4.8% zinc ingot, 1.6% magnesium ingot, 0.75% Al-20Cu alloy, 1.25% Al-20Mn alloy, 1.25% Al-10Cr alloy and 1.25% Al-10Zr alloy are stirred and melted into aluminum alloy liquid;

[0072] S...

Embodiment 3

[0080] The high-strength, toughness and anti-corrosion aluminum alloy for rail transit is composed of the following components in mass percentage: Zn 4.9%, Mg 1.5%, Cu 0.1%, Mn 0.3%, Cr 0.15%, Zr 0.15%, Ti 0.01%, B 0.002%, Fe≤0.15%, Si≤0.1%, the balance is Al and other unavoidable impurities, the individual content of other unavoidable impurities is ≤0.05%, and the total amount is ≤0.15%.

[0081] The extrusion method of the aluminum alloy comprises the following steps:

[0082] The first step: select Al-20Cu alloy, Al-20Mn alloy, Al-10Cr alloy, Al-10Zr alloy, Al-5Ti-1B alloy wire and aluminum ingots with a purity of 99.7%, zinc ingots with a purity of 99.9%, and purity 99.9% magnesium ingots are used as raw materials;

[0083] Step 2: Heat and melt the aluminum ingot at 780°C, then add 4.9% zinc ingot, 1.5% magnesium ingot, 0.5% Al-20Cu alloy, 1.5% Al-20Mn alloy, 1.5% Al-10Cr alloy and 1.5% Al-10Zr alloy are stirred and melted into aluminum alloy liquid;

[0084] Step 3: U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com