Ferritic heat-resistant steel used for coal-fired thermal power generation boiler piping and valve castings and preparation method thereof

A boiler tube and heat-resistant steel technology, applied in the field of metal materials, can solve the problems of lack of heat resistance and strong corrosion resistance, and achieve the effect of excellent high-temperature corrosion resistance, low price and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

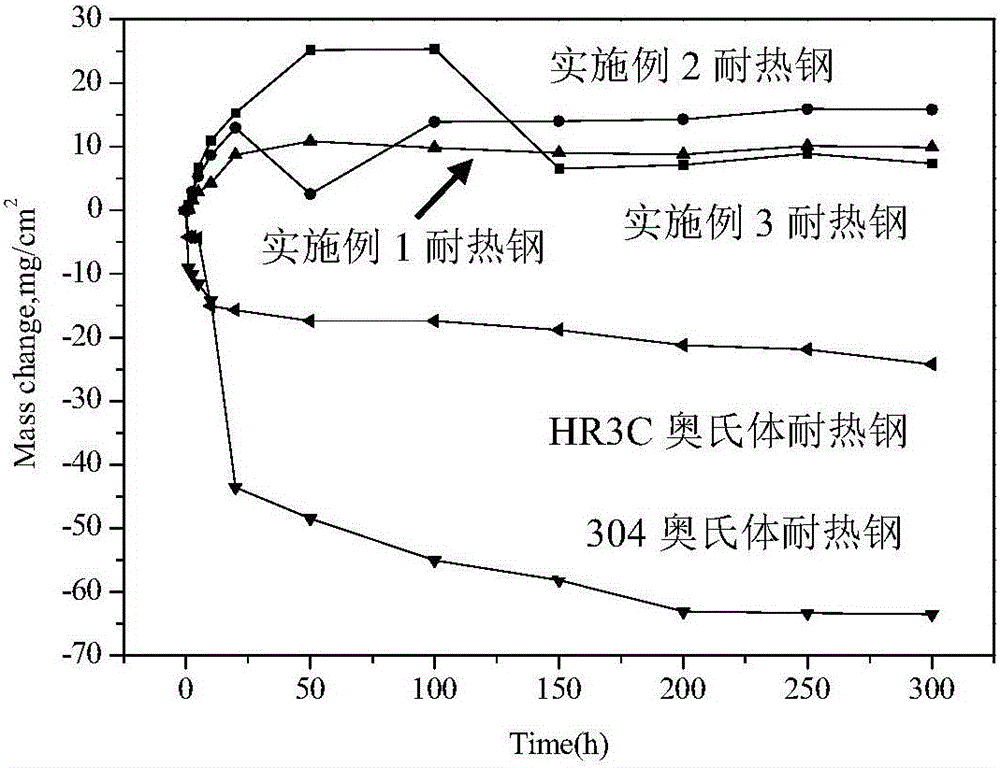

Embodiment 1

[0031] A ferritic heat-resistant steel used for coal-fired thermal power generation boiler pipelines and valve castings of the present invention, the ferritic heat-resistant steel used for coal-fired thermal power generation boiler pipelines and valve castings is calculated by mass percentage Consists of the following components:

[0032]

[0033]

[0034] The preparation method of the ferritic heat-resistant steel used for coal-fired thermal power generation boiler pipelines and valve castings according to the present invention comprises the following steps:

[0035] (1) Batching is carried out according to the above-mentioned component distribution ratio, and the selected furnace materials include: pig iron, scrap steel, ferrosilicon, ferromanganese, micro-carbon ferrochrome, ferro-niobium, ferro-vanadium, aluminum wire, etc.

[0036] The ferritic heat-resistant steel described in the present invention is developed to solve the serious corrosion problems faced by power...

Embodiment 2

[0055]The difference between Embodiment 2 and Embodiment 1 is that a ferritic heat-resistant steel used for coal-fired power generation boiler pipelines and valve castings of the present invention is used for coal-fired power generation boiler pipelines and valve castings. Ferritic heat-resistant steel consists of the following components by mass percentage:

[0056]

[0057]

[0058] The preparation method of the ferritic heat-resistant steel used for coal-fired thermal power generation boiler pipelines and valve castings according to the present invention comprises the following steps:

[0059] In step (2), the proportioned raw materials are smelted and cast; smelting equipment is used in the smelting, and the smelting equipment is a vacuum induction melting furnace.

[0060] In step (4), the normalizing process is as follows: install a furnace below 200°C, heat up at a rate of 40°C / h, keep warm at 1050°C, and then air-cool;

[0061] The tempering process is as follow...

Embodiment 3

[0063] The difference between embodiment 3 and embodiment 1 is:

[0064] A ferritic heat-resistant steel used for coal-fired thermal power generation boiler pipelines and valve castings of the present invention, the ferritic heat-resistant steel used for coal-fired thermal power generation boiler pipelines and valve castings is calculated by mass percentage Consists of the following components:

[0065]

[0066]

[0067] The preparation method of the ferritic heat-resistant steel used for coal-fired thermal power generation boiler pipelines and valve castings according to the present invention comprises the following steps:

[0068] In step (2), the proportioned raw materials are smelted and cast; smelting equipment is used in the smelting, and the smelting equipment is an electric arc melting furnace.

[0069] In step (4), the normalizing process is as follows: install the furnace below 200°C, the heating rate is equal to 80°C / h, keep warm at 1050°C, and then air cool;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com