Modification method for aluminum proximate matter for building

An aluminum profile, construction technology, applied in coatings, anti-corrosion coatings, etc., to achieve the effect of smooth surface, soft luster, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

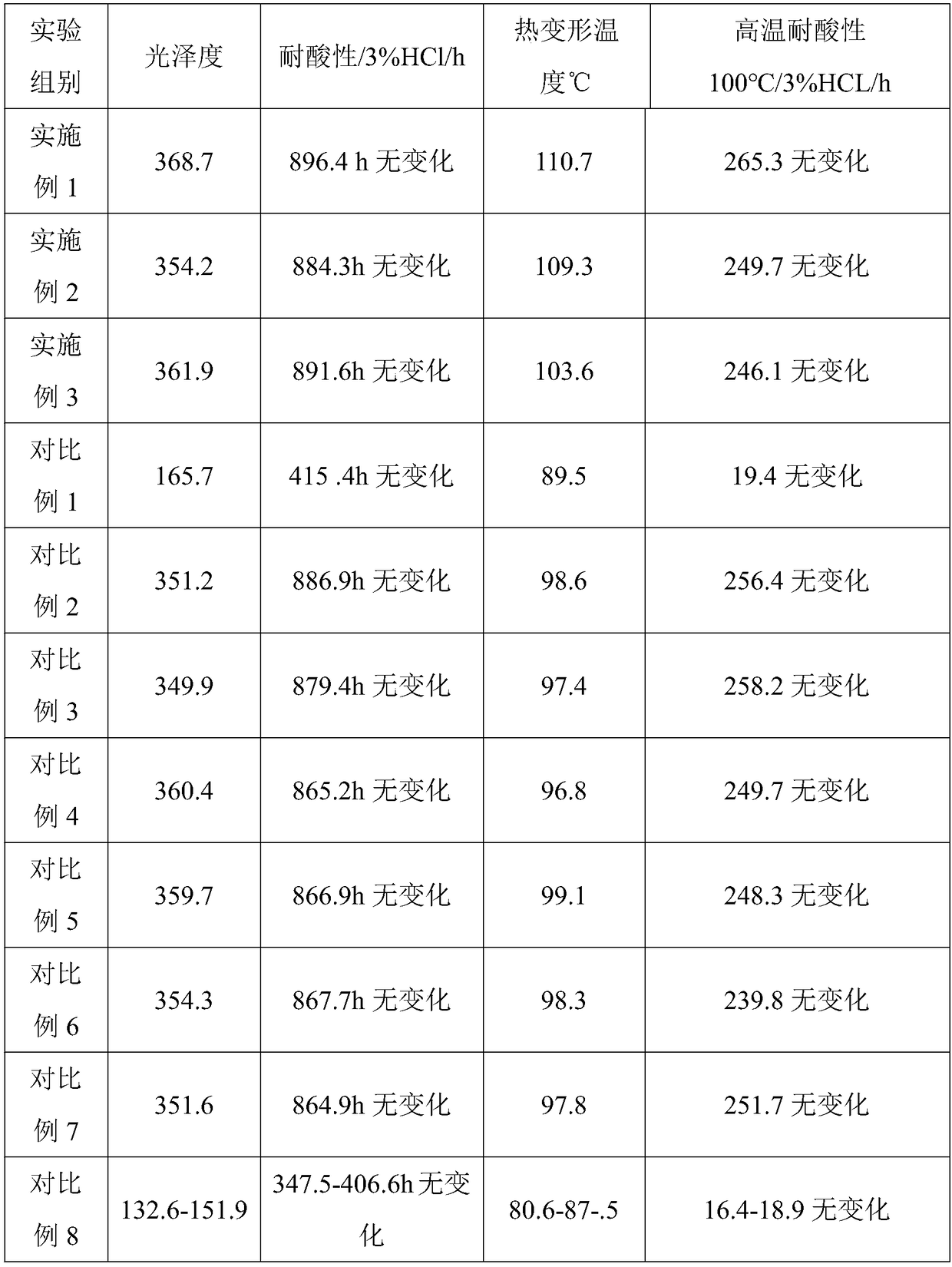

Examples

Embodiment 1

[0033] A method for modifying aluminum profiles for construction, comprising the following steps in sequence:

[0034] (1) Aluminum profile preparation: Melt zinc powder, magnesium powder, silicon powder, iron block, rhenium ingot, titanium ingot, boron powder, copper block, indium ingot, chromium powder and cerium ingot to obtain alloy liquid, and add aluminum zirconium Coated titanium dioxide and zirconium-coated silica mixed powder, then kept at the melting temperature for 4.6h, and then poured into a mold above 600°C under a pressure of 1.3Mpa, preheated the casting at 986°C for 44min, then heated for 42min, and kept warm 2.9h, then carry out pre-cooling treatment in clean water, the time of pre-cooling treatment is 3.6min, the casting after pre-cooling treatment is put into brine solution for quenching treatment, the temperature of quenching treatment is 774 ℃, the time of quenching treatment is 6.8min, put After the quenching treatment, the casting is heated to 180-210°C...

Embodiment 2

[0043] A method for modifying aluminum profiles for construction, comprising the following steps in sequence:

[0044] (1) Aluminum profile preparation: Melt zinc powder, magnesium powder, silicon powder, iron block, rhenium ingot, titanium ingot, boron powder, copper block, indium ingot, chromium powder and cerium ingot to obtain alloy liquid, and add aluminum zirconium Coated titanium dioxide and zirconium-coated silica mixed powder, then kept at the melting temperature for 3.6h, and then poured into a mold above 600°C under a pressure of 1.4Mpa, preheated the casting at 998°C for 39min, then heated for 42min, and kept warm 2.4h, then carry out pre-cooling treatment in clean water, the time of pre-cooling treatment is 3.9min, the casting after pre-cooling treatment is put into brine solution for quenching treatment, the temperature of quenching treatment is 779 ℃, the time of quenching treatment is 6min, quenching The treated casting is heated to 198°C for tempering treatmen...

Embodiment 3

[0053] A method for modifying aluminum profiles for construction, comprising the following steps in sequence:

[0054] (1) Aluminum profile preparation: Melt zinc powder, magnesium powder, silicon powder, iron block, rhenium ingot, titanium ingot, boron powder, copper block, indium ingot, chromium powder and cerium ingot to obtain alloy liquid, and add aluminum zirconium Coated titanium dioxide and zirconium-coated silica mixed powder, then kept at the melting temperature for 3.4h, and then poured into a mold above 600°C under a pressure of 1.2Mpa, preheated the casting at 977°C for 38min, then heated for 44min, and kept warm 2.2h, then pre-cooling treatment in clean water, the pre-cooling treatment time is 3.9min, the casting after pre-cooling treatment is put into the brine solution for quenching treatment, the quenching treatment temperature is 764 ° C, the quenching treatment time is 5min, the quenching treatment The treated casting is heated to 206°C for tempering treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com