Heat-resistant steel used for ethylene cracking furnace tube material, and preparation method for ethylene cracking furnace tube

An ethylene cracking furnace and heat-resistant steel technology are applied in the field of heat-resistant steel to achieve good high-temperature mechanical properties, improved service life, and good oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

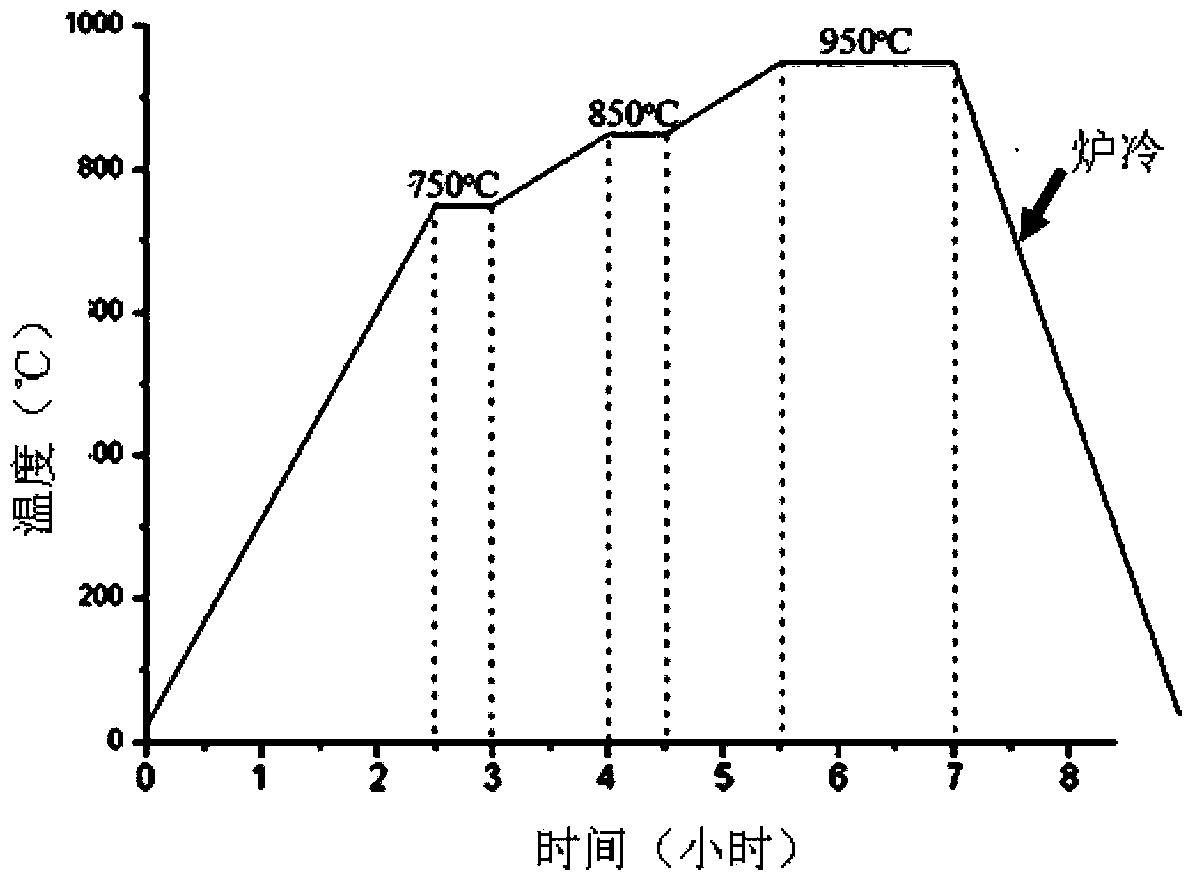

Embodiment 1

[0028] 1) The chemical composition of the heat-resistant steel used for the material of the heat-resistant steel ethylene cracking furnace tube in this embodiment, the composition in weight percentage is: 0.5C, 1.5Si, 1.5Mn, 30Cr, 20Ni, 0.5Nb, 0.1 rare earth Ce, S≤ 0.03%, P≤0.03%, the rest is Fe.

[0029] 2) Calculate and weigh the above-mentioned raw materials for heat-resistant steel smelting: steel scrap, ferromanganese and ferrosilicon, ferrochromium, pure nickel, ferroniobium, and rare earth cerium, and make batches.

[0030] 3) Heat scrap steel in an electric furnace to 1400°C to melt. After the molten steel is melted, ferromanganese and ferrosilicon are added in turn to make the temperature reach 1500°C. After deoxidizing with aluminum wire, pure nickel, ferroniobium, and After ferrochrome, make the temperature of molten steel reach 1600℃ at this time, deoxidize with aluminum wire again and remove slag on the liquid surface of molten steel, then quickly pour molten stee...

Embodiment 2

[0035] 1) The chemical composition of the heat-resistant steel used for the material of the heat-resistant steel ethylene cracking furnace tube in this embodiment, the composition in weight percentage is: 1.5C, 0.5Si, 0.5Mn, 35Cr, 15Ni, 0.1Nb, 0.05 rare earth Ce, S≤ 0.03%, P≤0.03%, the rest is Fe.

[0036] 2) Calculate and weigh the above-mentioned raw materials for heat-resistant steel smelting: steel scrap, ferromanganese and ferrosilicon, ferrochromium, pure nickel, ferroniobium, and rare earth cerium, and make batches.

[0037]3) Heat scrap steel in an electric furnace to 1400°C and melt it. After the molten steel is melted, ferromanganese and ferrosilicon are added in turn to make the temperature reach 1500°C. After deoxidizing with aluminum wire, pure nickel, ferroniobium, After ferrochrome, the temperature of the molten steel reaches 1600°C at this time, and the aluminum wire is used to deoxidize again, and the slag is removed on the liquid surface of the molten steel, ...

Embodiment 3

[0042] 1) The chemical composition of the heat-resistant steel used for the material of the heat-resistant steel ethylene cracking furnace tube in this embodiment, in terms of weight percentage, is: 1.0C, 1.2Si, 1.2Mn, 32Cr, 18Ni, 0.25Nb, 0.08 rare earth Ce, S≤ 0.03%, P≤0.03%, the rest is Fe.

[0043] 2) Calculate and weigh the above-mentioned raw materials for heat-resistant steel smelting: steel scrap, ferromanganese and ferrosilicon, ferrochromium, pure nickel, ferroniobium, and rare earth cerium, and make batches.

[0044] 3) Heat scrap steel in an electric furnace to 1400°C and melt it. After the molten steel is melted, ferromanganese and ferrosilicon are added in turn to make the temperature reach 1500°C. After deoxidizing with aluminum wire, pure nickel, ferroniobium, After ferrochrome, the temperature of the molten steel reaches 1600°C at this time, and the aluminum wire is used to deoxidize again, and the slag is removed on the liquid surface of the molten steel, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com