Stainless steel for oil wells and stainless steel pipe for oil wells

A technology for stainless steel and oil wells, which is applied in the field of stainless steel for oil wells and stainless steel pipes for oil wells. It can solve the problems of high price and achieve the effect of high strength and excellent high temperature corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

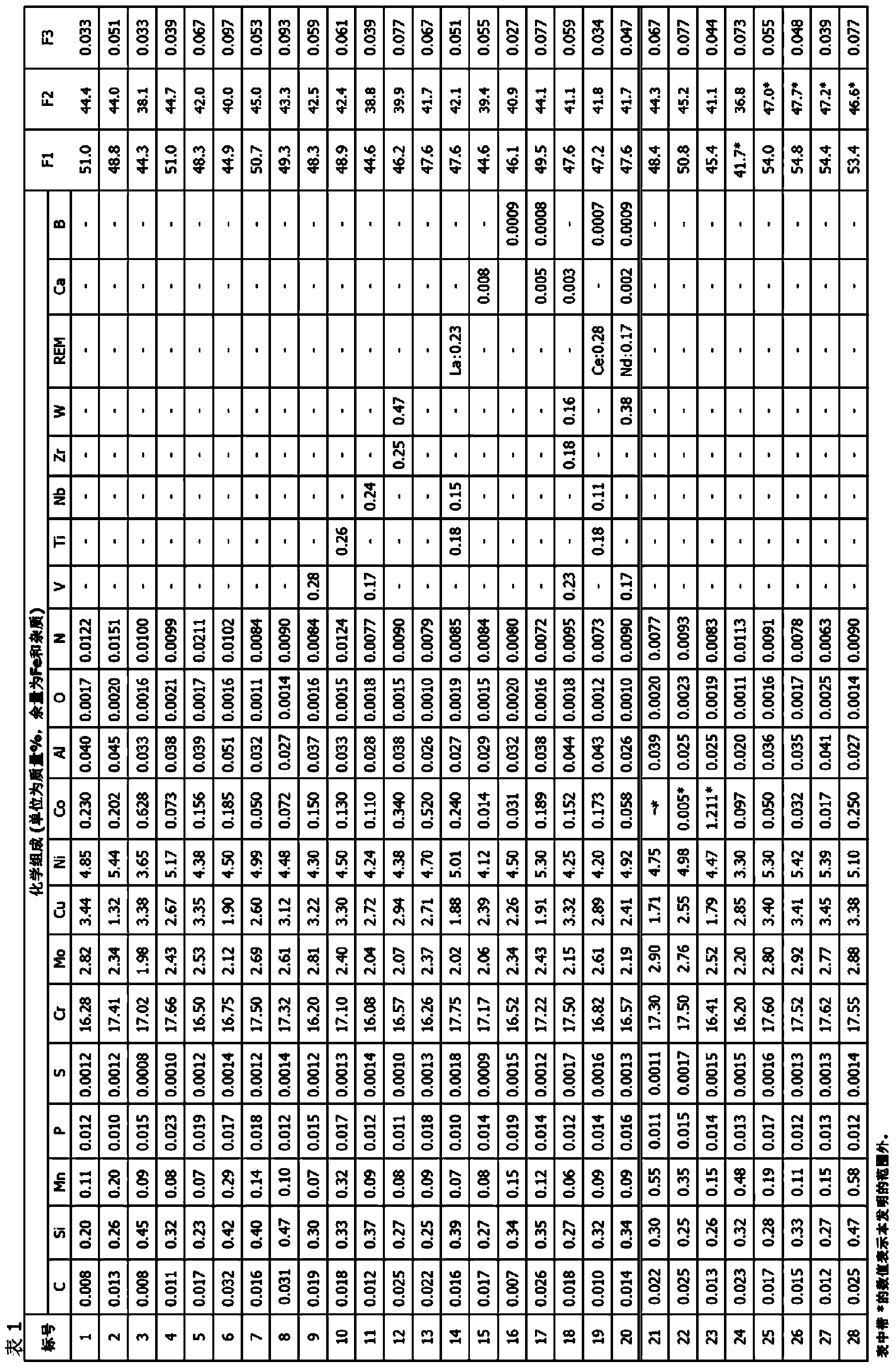

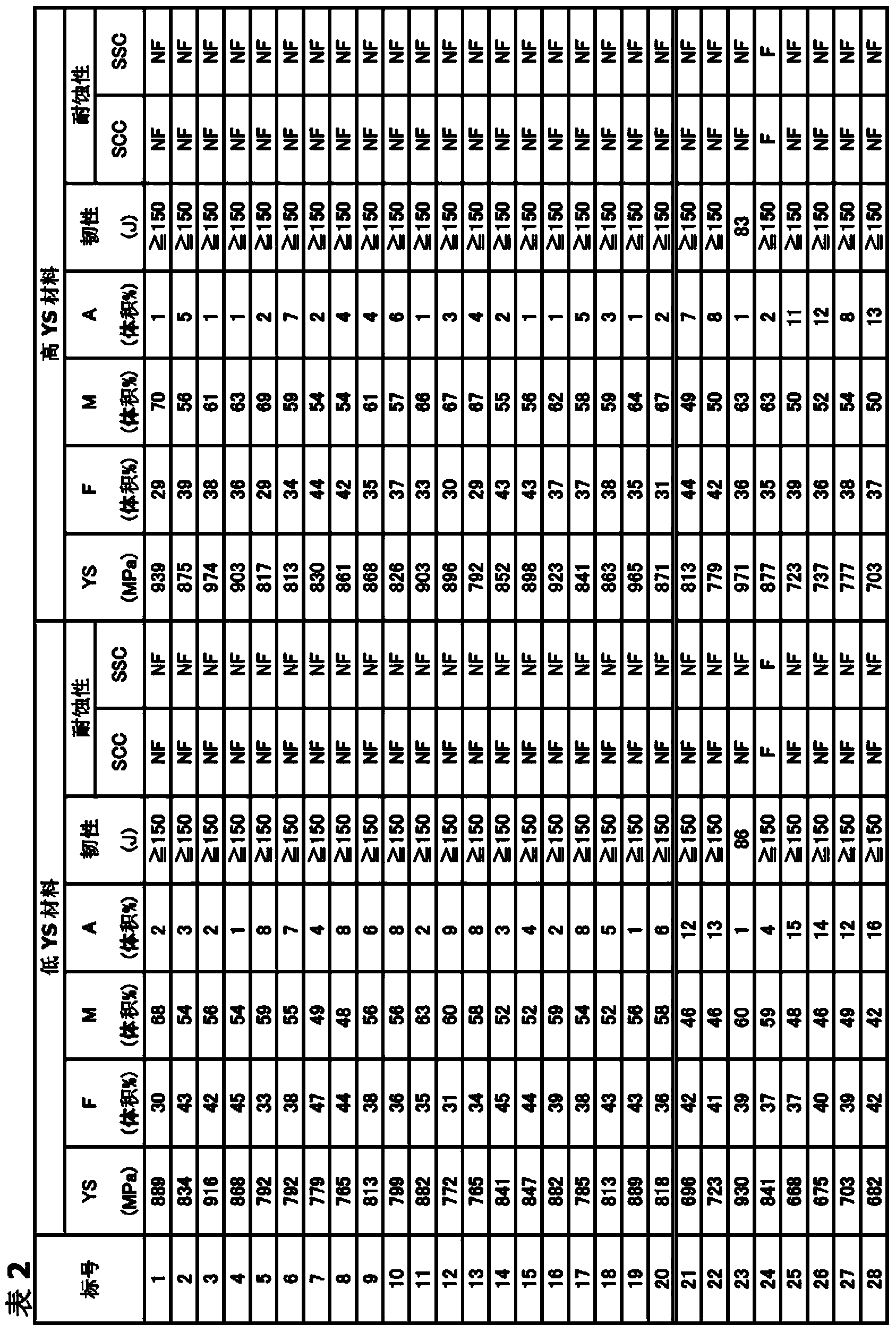

[0121] Steels of numbers 1 to 28 having the chemical compositions shown in Table 1 were melted, and cast slabs were produced by continuous casting.

[0122] [Table 1]

[0123]

[0124] Referring to Table 1, steels with numbers 1 to 20 are within the scope of the present invention. On the other hand, the chemical compositions of Nos. 21 to 28 are outside the scope of the present invention.

[0125] Roll the billets of each label with a blooming mill to manufacture round billets. The diameter of the round billet of each steel was 232 mm. Next, the outer surface of each round billet was cut so that the diameter of the round billet was 225 mm.

[0126] Each round billet is heated to 1150-1200°C in a heating furnace. After heating, each round billet is hot rolled. Specifically, a round billet is pierced and rolled using a piercer to manufacture a pipe. The tube blank is stretched and rolled with a mandrel type seamless tube rolling mill, and then the diameter is reduced, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com