High-strength high-toughness polypropylene blending composite material and preparation method thereof

A high-toughness polypropylene and composite material technology, applied in the field of polymer processing, can solve the problems of complex material preparation process, poor compatibility, and poor toughening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

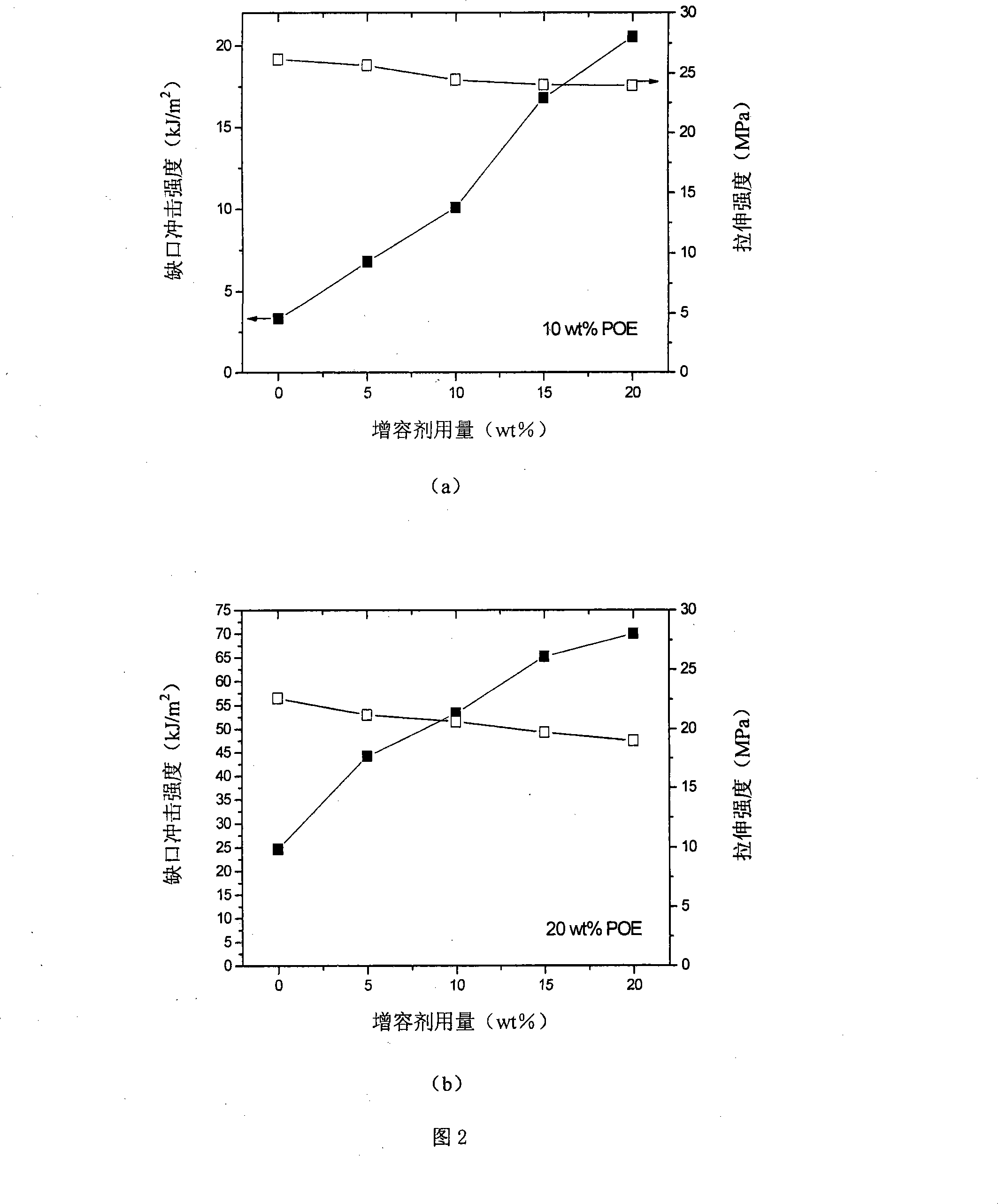

[0031]After melting 200g of PP in an internal mixer, add 0.2g of dicumyl peroxide (DCP), 2-tert-butyl-6-(3-tert-butyl-2-hydroxy-5-methylbenzyl )-4-methylphenyl acrylate (BPA) 6g, react at a reaction temperature of 190°C and a rotation speed of 60rpm for 10min to obtain a compatibilizer PP-g-BPA.

[0032] Mix 10Kg of PP, 500g of PC, 100g of PP-g-BPA, and 10g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester, and melt them with a twin-screw extruder Mixing, the extruder barrel temperature is 230-270°C, the screw speed is 50 rpm, extruded and granulated, and dried at a temperature of 90°C for 3 hours to obtain a high-strength and high-toughness polypropylene blended composite material.

Embodiment 2

[0034] After melting 200g of PP in an internal mixer, add 2g of dicumyl peroxide (DCP) and 16g of 2-allyl bisphenol A (2A) in sequence, and react at a reaction temperature of 170°C and a rotation speed of 30rpm for 5min to obtain Compatibilizer PP-g-2A.

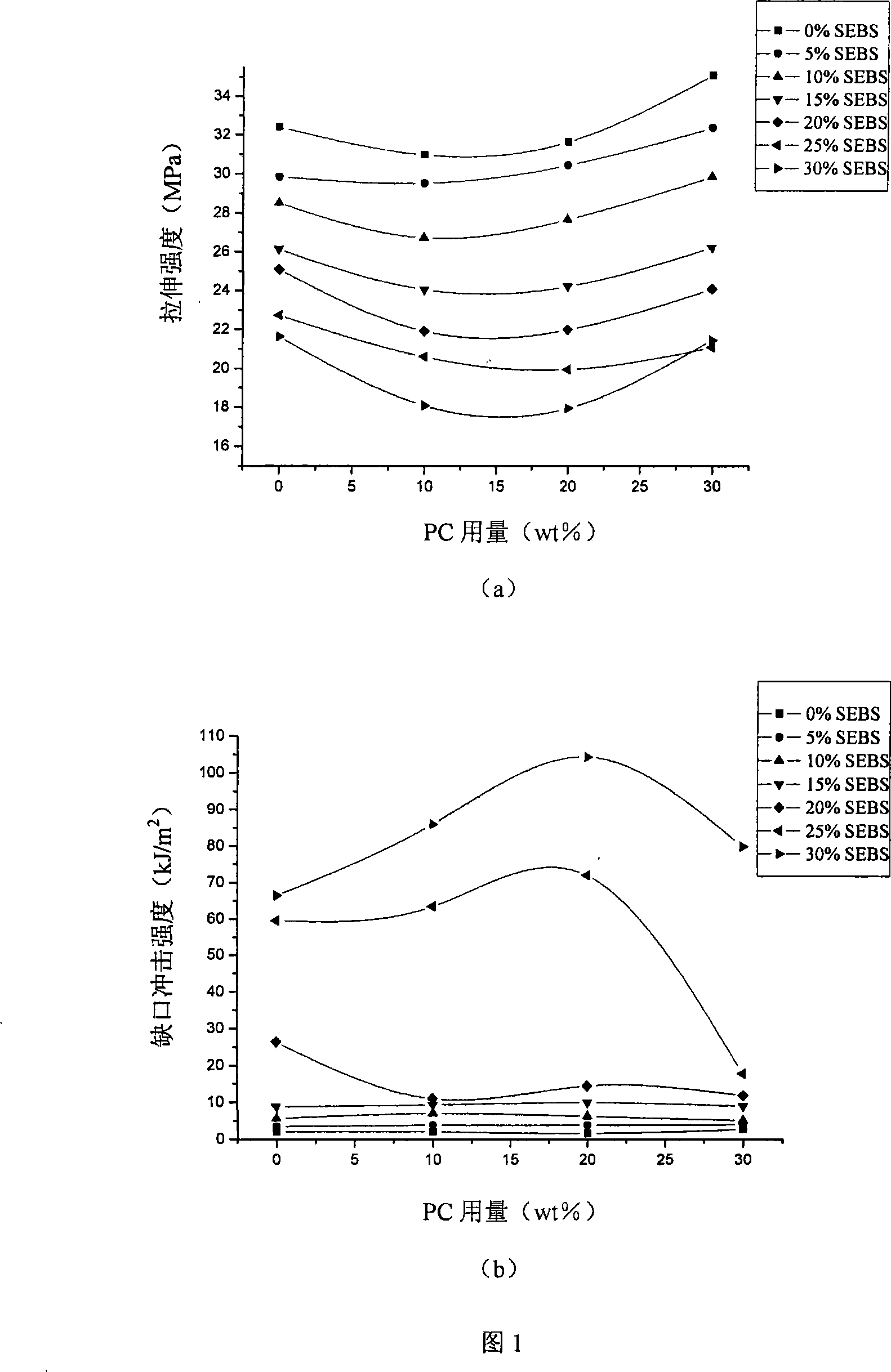

[0035] Mix PP 10Kg, PC 1.5Kg, SEBS 2Kg, PP-g-2A 300g, bis[3-(3-tert-butyl-5-methyl-4-hydroxyphenyl)propionate triethylene glycol ester 30g Uniform, melted and kneaded by twin-screw extruder, extruder barrel temperature is 230-270 ° C, screw speed is 100 rpm, extruded and granulated, dried at 80 ° C for 4 hours, obtained high-strength and high-toughness polymer Propylene blend composite.

Embodiment 3

[0037] Mix 10Kg of PP, 3Kg of PC, 5Kg of SEBS, and 50g of bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] 1,6-hexanediol, and extrude with twin-screw Melting and kneading by machine, the barrel temperature of the extruder is 230-270 ° C, the screw speed is 150 rpm, extruded and granulated, and dried at 100 ° C for 2 hours to obtain a high-strength and high-toughness polypropylene blended composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com