PO film serving as emulsion explosive filling film and preparation method thereof

An emulsion explosive, weight percentage technology, applied in the field of composite membranes, can solve the problems of not being able to have good heat resistance, cold resistance and chemical stability at the same time, unscientific, etc., achieve good mechanical strength, improve mechanical properties and barrier properties, Effect of good heat resistance and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with specific examples, but this does not constitute any limitation to the present invention.

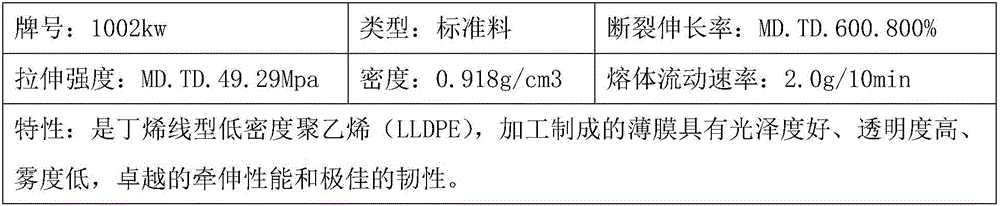

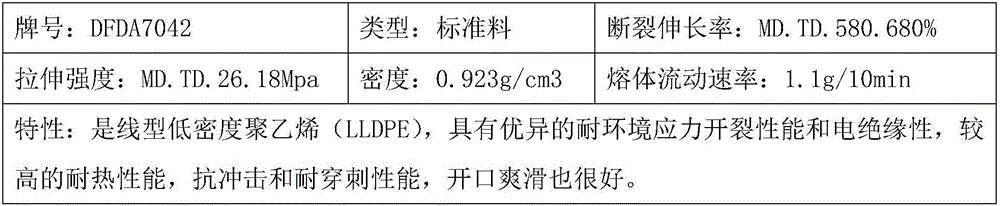

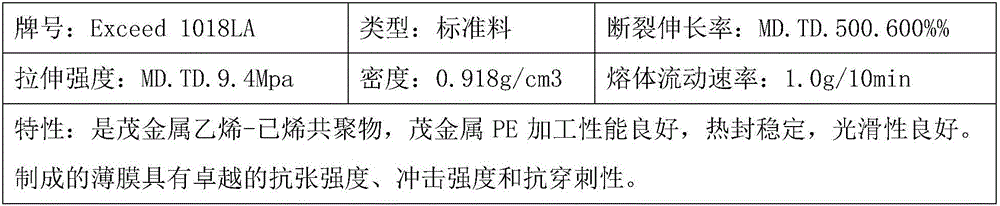

[0016] A PO membrane used for emulsified explosive filling membrane according to the present invention, the PO membrane is composed of an outer layer, a middle layer and an inner layer stacked in sequence; the outer layer is made of the following raw materials in weight percentage: reinforced polymer Ethylene 60wt%-80wt% and butene linear low-density polyethylene 20wt%-40wt%; the outer layer prepared by the above formula, its function and characteristics: it can show good mechanical properties at low temperature, and has excellent resistance Environmental stress cracking resistance, excellent stiffness, impact strength balance provides the feasibility of thickness reduction, while maintaining film properties, good gloss, high transparency, low haze, excellent drawability and excellent toughness . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com