Carbon black water-based color paste with high carbon black content and preparation method thereof

A technology of water-based color paste and high carbon black, applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, cosmetic preparations, etc., can solve the problems of complex process, high cost, poor repeatability, etc., and achieve simple production process and easy The effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

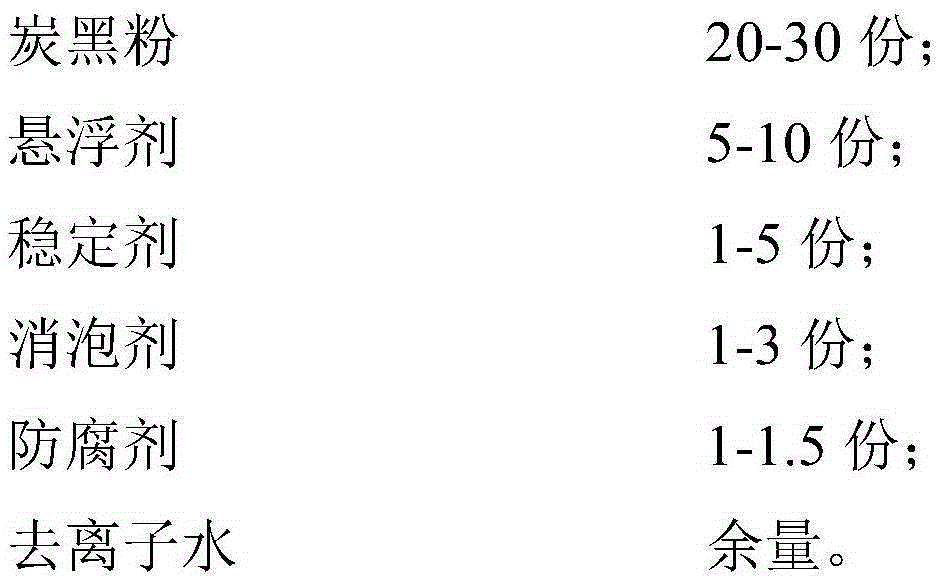

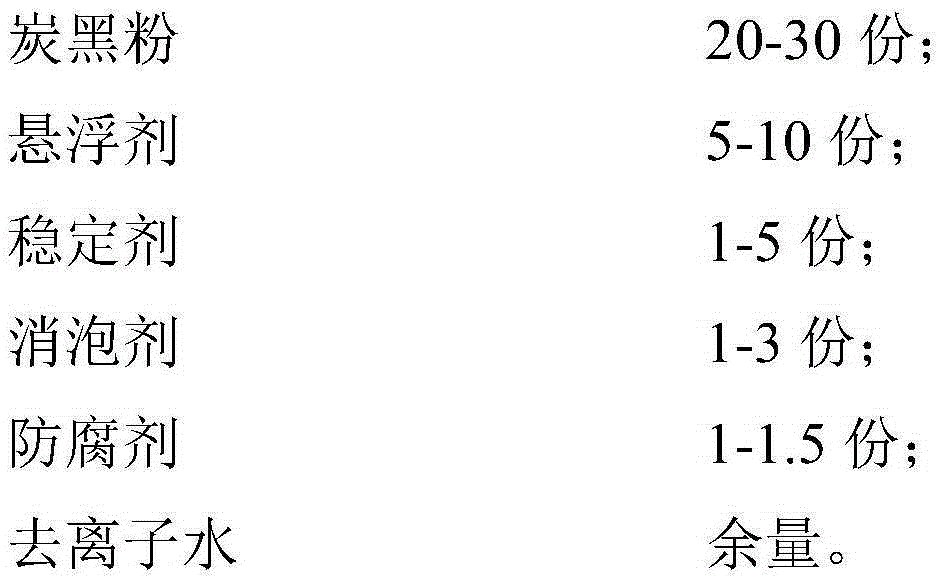

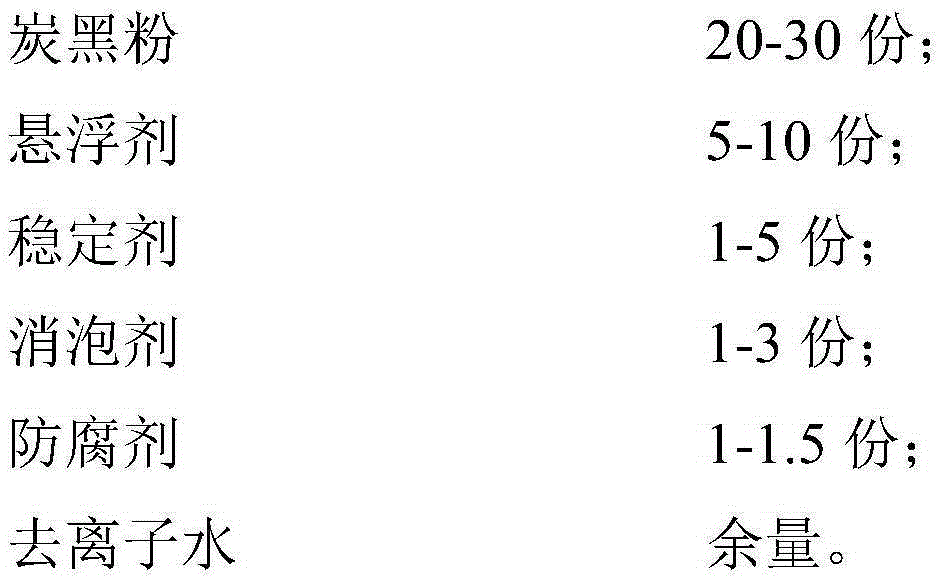

[0041] For the carbon black water-based color paste composed of the above components according to the corresponding proportions, this solution also provides a corresponding preparation method, which includes the following steps:

[0042] (1) Heat 50-60 parts of deionized water to above 85°C, add 5-10 parts of suspending agent into it, stir and dissolve completely, then cool to normal temperature to obtain solution 1.

[0043] In order to achieve a better effect and ensure the quality of the carbon black water-based color paste, specifically heat the ionized water to 85-90°C.

[0044] (2) Add 1-5 parts of stabilizer to solution 1 to obtain mixed solution 2.

[0045] (3) Add 1-3 parts of defoamer into mixed solution 2 to obtain mixed solution 3.

[0046] (4) Add the mixed solution 3 into the high-speed mixer container.

[0047] (5) Add 20-30 parts of carbon black powder into the stirring container.

[0048] (6) Stir at a high speed for a period of time to disperse the carbon ...

Embodiment 1

[0055] In this example, carbon black water-based color paste is prepared by the following process:

[0056] (1) Weigh 100g of deionized water and heat it to 85°C for disinfection.

[0057] (2) Weigh 8g of carboxymethyl cellulose and add it to 56g of hot deionized water, stir to dissolve it, cool to normal temperature, replenish evaporated water, and pour it into a stirring pot.

[0058] (3) Weigh 3g of sodium chloride and add it to the stirring pot.

[0059] (4) Weigh 2g of silicon dioxide and add it into the stirring pot.

[0060] (5) Weigh 30g of carbon black powder and add it to the stirring pot.

[0061] (6) Stir the stirring pot at high speed to disperse the carbon black evenly, wherein the stirring speed is 1500-2000r / min, the temperature is 20-70°C, and the stirring time is 1.5-2h.

[0062] (7) Put the stirring pot into cold water and cool it to below 50°C, add 1 g of Nepalese propane, and stir for another 5 minutes to obtain a color slurry.

[0063] (8) Filter the ...

Embodiment 2

[0071] In this instance, prepare nano-carbon black dispersion slurry by following process:

[0072] (1) Weigh 100g of deionized water and heat it to 85 μg.

[0073] (2) Weigh 8g of PVP and add it to 56g of hot deionized water, stir to dissolve it, cool to normal temperature, add evaporated water, and pour it into a stirring pot.

[0074] (3) Weigh 3g of magnesium chloride and add it to the stirring pot.

[0075] (4) Weigh 2g of silicon dioxide powder and add it into the stirring pot.

[0076] (5) Weigh 30g of carbon black powder and add it to the stirring pot.

[0077] (6) Stir the stirring pot at high speed to disperse the carbon black evenly, wherein the stirring speed is 1500-2000r / min, the temperature is 20-70°C, and the stirring time is 1.5-2h.

[0078] (7) Put the stirring pot into cold water and cool it to below 50°C, add 1 g of Nepalese propane, and stir for another 5 minutes to obtain a color slurry.

[0079] (8) Filter the color slurry through a 200-mesh filter c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com