Cylindrical head suspension type insulator-head sanding process

A technology for suspension insulators and cylindrical heads, which is applied in the field of sanding technology on the head of cylindrical head suspension insulators. It can solve the problems of affecting the smoothness of the sanding surface, poor combination of dry billets and porcelain sand, and cracks in porcelain sand, and achieves The effect of uniform distribution of electric strength, enhanced bonding strength, and improved electric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A process of sanding the head of a cylindrical head suspension insulator, including the following steps:

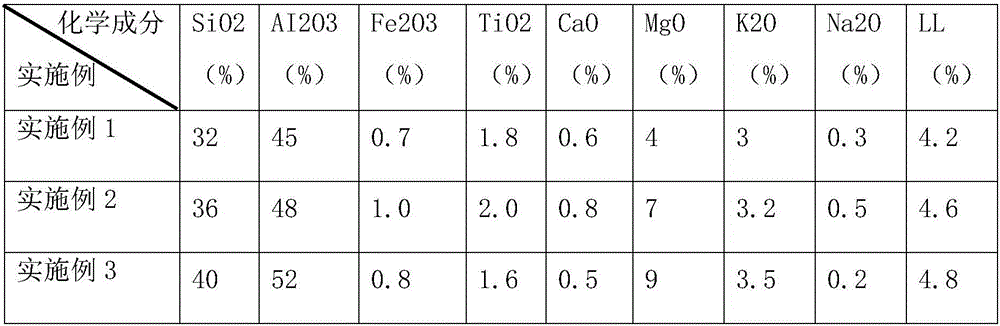

[0029] S1: Proportion of raw materials: First, select the raw materials of porcelain sand and sand-coated glaze. The porcelain sand includes the following components in mass parts: Dongsheng soil 24g, Jingyang soil 10g, low-titanium bauxite 35g, Jiangjin clay clay 10g, carbonic acid Magnesium 4g, high potassium and low iron feldspar 4g;

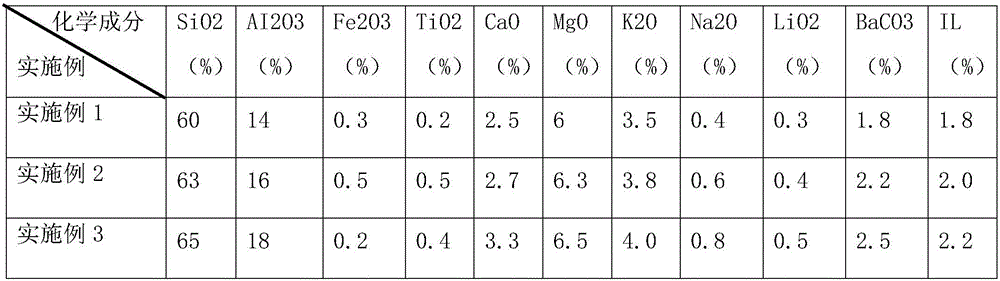

[0030] The sand-coated glaze includes the following components in parts by mass: 25g of potassium feldspar, 14g of lime powder, 3g of earth, 4g of limestone, 16g of forged talc, 3g of potassium pyroxene, 1g of barium carbonate, 10g of high-strength blank, and 6g of ordinary blank;

[0031] S2: Porcelain sand treatment: prepare and ball mill according to the raw material composition of the above porcelain sand, add water during the ball milling process to form mud; squeeze the mud to form a mud cake, and then vacuum e...

Embodiment 2

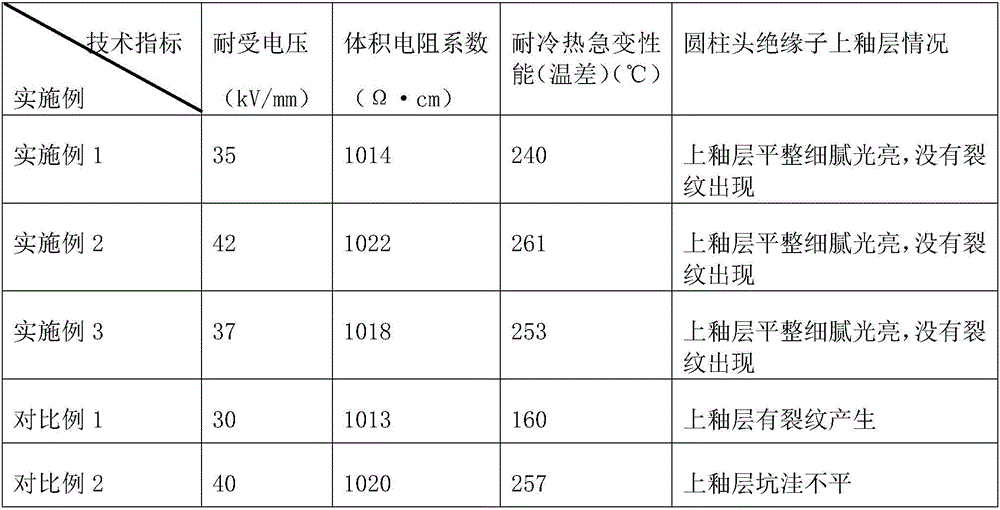

[0057] The data of withstand voltage, volume resistivity, cold and heat shock resistance (temperature difference) of Example 2 are the highest, and the withstand voltage and cold and heat resistance of the cylindrical head insulator formed by it are the best.

[0058] Compared with Comparative Example 1, Example 2 has the worst data on the withstand voltage, volume resistivity, and thermal shock resistance (temperature difference) of the cylindrical head insulator produced in Comparative Example 1, and the combination of sand and glaze is not good, and no intermediate transition is set. layer, causing cracks in the glazed layer.

[0059] Compared with Comparative Example 2, Example 2 has better withstand voltage, volume resistivity, thermal shock resistance (temperature difference) data of the cylindrical head insulator formed in Comparative Example 2, but the glaze layer is uneven. The main reason is that in the pre-treatment process of the sand-coated glaze, the iron slag in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Withstand voltage | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com