Abrasion-resistant prefabricated part with high heat shock-resistant property for dry quenching coke tank and preparation method thereof

A technology of prefabricated parts and coke, which is applied in the field of prefabricated parts with high thermal shock resistance and wear resistance for CDQ coke tanks and prefabricated parts for coking equipment, which can solve the problems of poor shock resistance and high cost of stainless steel materials. High, heat-resistant cast iron with high hardness, etc., to achieve the effects of excellent shock resistance, extended service life, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

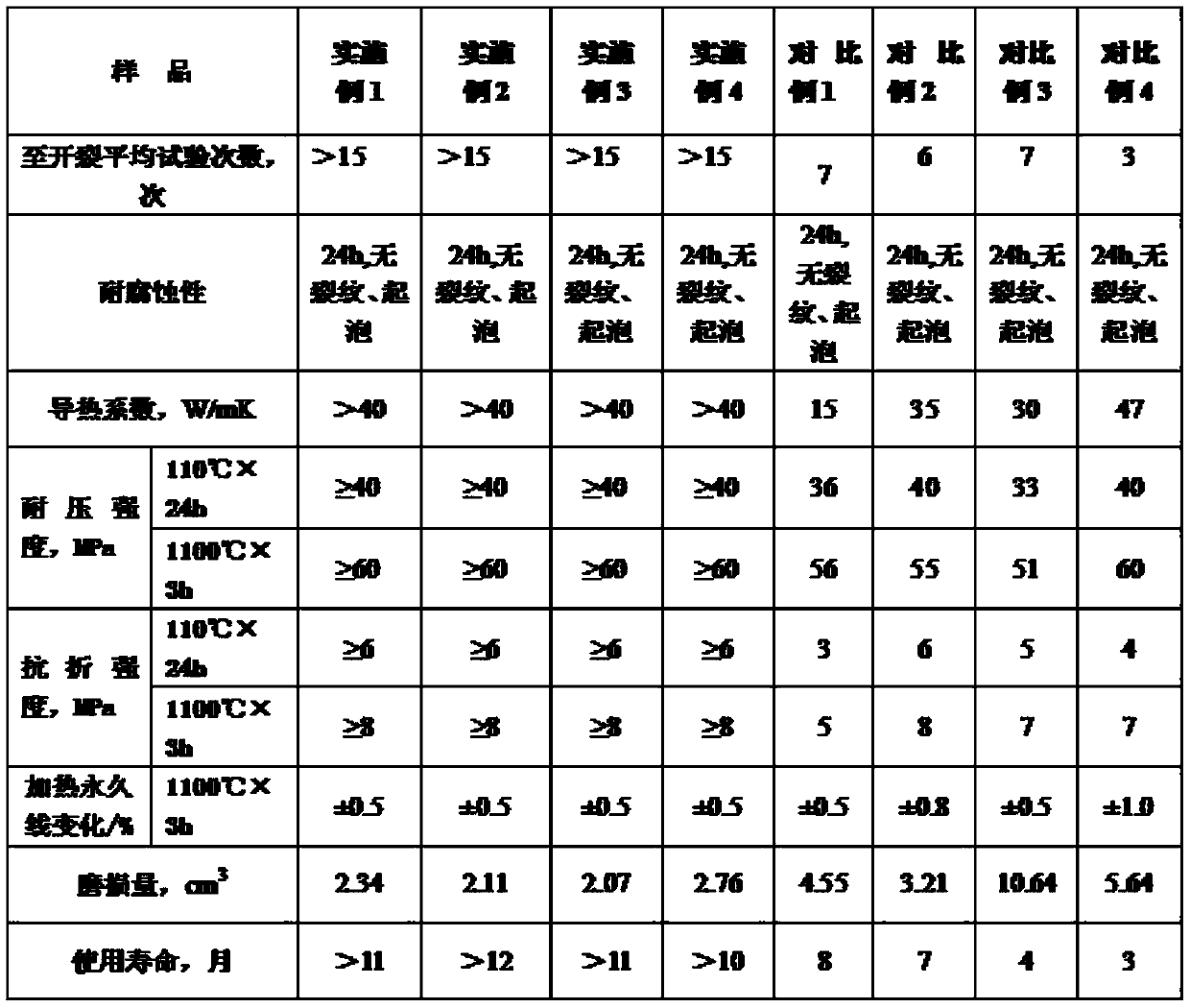

Examples

Embodiment 1

[0036] A prefabricated part with high thermal shock resistance and wear resistance for CDQ coke tanks, which is prepared from the following raw materials in parts by weight:

[0037] Silicon carbide whiskers 20 parts;

[0038] 40 parts of alumina-based homogeneous material;

[0039] 5 parts of silicon dioxide micropowder;

[0040] 1 part of water;

[0041] 0.2 part of polycarboxylate superplasticizer;

[0042] α-Al 2 o 3 15 parts of powder;

[0043] MoSi 2 8 servings of powder.

[0044] The silicon carbide whiskers described herein have a diameter of 0.1-2um, a length of 20-300um, and a powdery appearance.

[0045] The content of aluminum chloride in the bauxite-based homogeneous material mentioned therein is 88wt%, and the bauxite ore green body with 75wt% aluminum chloride content is fired at 1500°C for 4 hours, and the bulk density after firing is 2.92g·cm -3 .

[0046] The particle size of the silicon dioxide micropowder is 50-100nm.

[0047] α-Al described in ...

Embodiment 2

[0054] A prefabricated part with high thermal shock resistance and wear resistance for CDQ coke tanks, which is prepared from the following raw materials in parts by weight:

[0055] Silicon carbide whiskers 25 parts;

[0056] 50 parts of alumina-based homogeneous materials;

[0057] 8 parts of silicon dioxide micropowder;

[0058] 2 parts of water;

[0059] 0.3 part of polycarboxylate superplasticizer;

[0060] α-Al 2 o 3 18 parts of powder;

[0061] MoSi 2 Powder 10 parts.

[0062] The silicon carbide whiskers described herein have a diameter of 0.1-2um, a length of 20-300um, and a powdery appearance.

[0063] The content of aluminum chloride in the bauxite-based homogeneous material mentioned therein is 88wt%, and the bauxite green body with 75wt% aluminum chloride content is fired at 1550°C for 4 hours, and the bulk density after firing is 2.98g·cm -3 .

[0064] The particle size of the silicon dioxide micropowder is 50-100nm.

[0065] α-Al described in 2 o 3...

Embodiment 3

[0072] A prefabricated part with high thermal shock resistance and wear resistance for CDQ coke tanks, which is prepared from the following raw materials in parts by weight:

[0073] Silicon carbide whiskers 28 parts;

[0074] 53 parts of alumina-based homogeneous materials;

[0075] 8 parts of silicon dioxide micropowder;

[0076] 2 parts of water;

[0077] 0.5 part of polycarboxylate superplasticizer;

[0078] α-Al 2 o 3 19 parts of powder;

[0079] MoSi 2 Powder 11 parts.

[0080] The silicon carbide whiskers described herein have a diameter of 0.1-2um, a length of 20-300um, and a powdery appearance.

[0081] The content of aluminum chloride in the bauxite-based homogeneous material mentioned therein is 88wt%, and the bauxite ore green body with 75wt% aluminum chloride content is fired at 1570 ° C for 4 hours, and the bulk density after firing is 3.32g·cm -3 .

[0082] The particle size of the silicon dioxide micropowder is 50-100nm.

[0083] α-Al described in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com