Non-sticky steel converter oxygen lance and manufacturing method thereof

The technology of a converter oxygen lance and its production method is applied in the direction of manufacturing converters, etc., which can solve the problems of adverse effects of smelting time, ineffectiveness, inconvenient operation, etc., achieve great economic benefits and use value, reduce the number of replacements, reduce The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

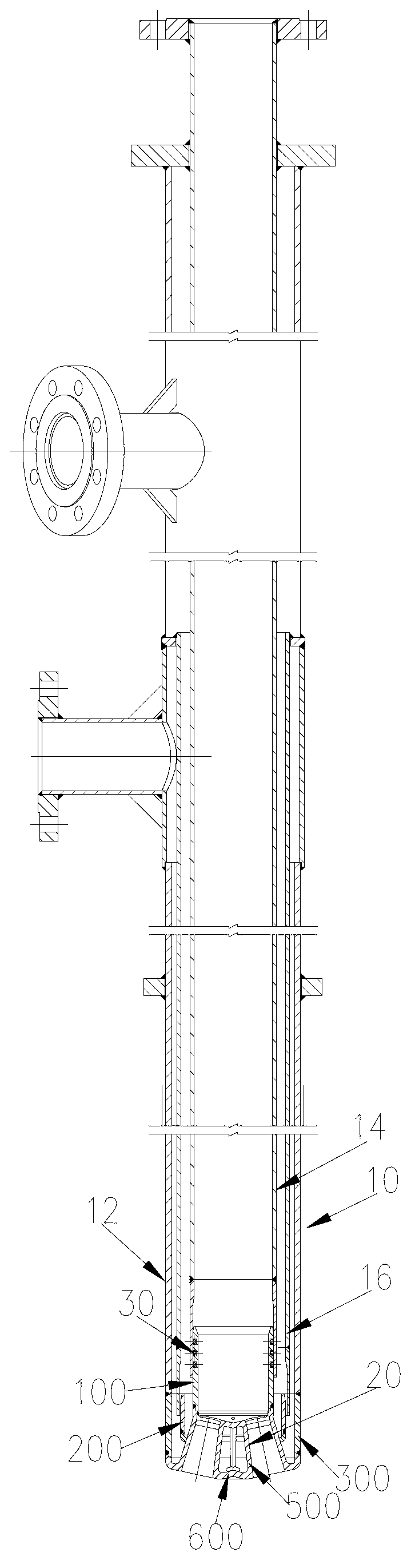

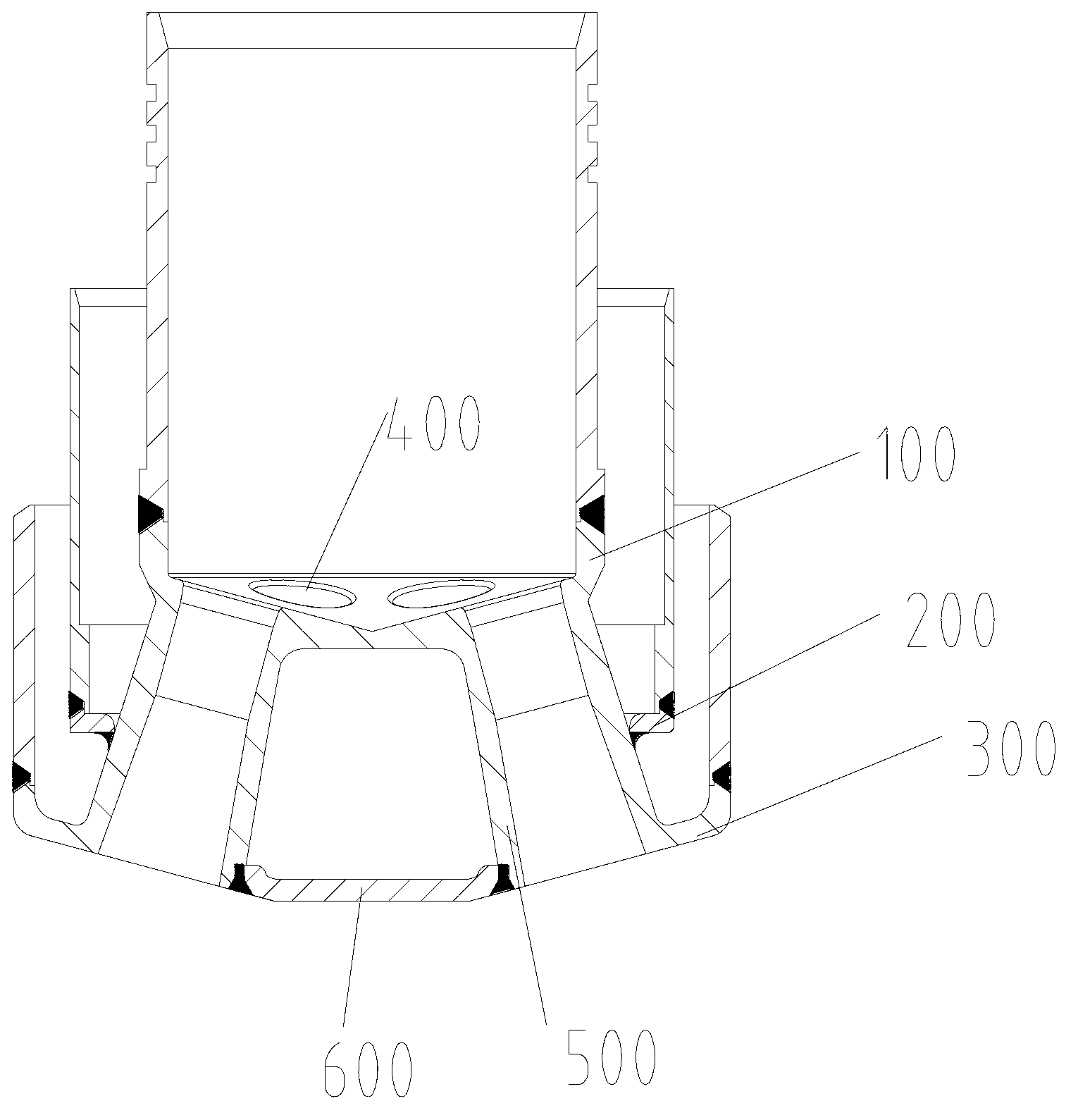

[0019] Example: such as Figure 1-2 As shown, the present invention provides a specific embodiment of a non-stick steel converter oxygen lance, which includes an oxygen lance adapter 10 and an oxygen lance nozzle 20 positioned at the bottom of the oxygen lance adapter 10, wherein the oxygen lance adapter 10 or the oxygen lance nozzle 20 There is a composite coating on the outside, and the composite coating at least includes an adhesive layer attached to the outside of the oxygen lance nozzle 10 or the oxygen lance nozzle 20, a high temperature resistant layer, and a non-stick layer on the outside. The composite coating has sufficient refractoriness and high temperature stability, and has good viscosity and thixotropy to ensure a smooth coating surface after spraying; it has good suspension and storage properties to ensure that the coating does not delaminate within a specified time , no precipitation, agglomeration, stable performance and no deterioration; abundant raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com