Environment-friendly rice husk ash porcelain blank and preparation method

A technology for husk ash and ceramic blanks, applied in the production of ceramic materials, clay products, other household appliances, etc., can solve problems such as loss of market competitiveness, achieve high use value, save resources, and maintain ecological balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: according to the preparation method of aforementioned environment-friendly chaff ash ceramic blank, make according to the following steps:

[0026] ① Weigh 30 parts of kaolin, 10 parts of feldspar, 35 parts of quartz and 50 parts of chaff ash and mix them to obtain product A;

[0027] ②According to product A: grinding ball: water = 1: 1.8: 0.7 weight ratio, enter ball mill and ball mill for 28 hours, let the slurry go, pass through a 180 mesh sieve, and then remove iron to obtain slurry, which is product B;

[0028] ③ Press filter dehydration of product B to make a mud cake with a moisture content of 21%.

Embodiment 2

[0029] Embodiment 2: according to the preparation method of aforementioned environment-friendly chaff ash ceramic billet, make according to the following steps:

[0030] ① Weigh 45 parts of kaolin, 15 parts of feldspar, 25 parts of quartz and 25 parts of chaff ash and mix them to obtain product A;

[0031] ②According to product A: grinding ball: water=1: 1.8: 0.7 weight ratio, put into ball mill and ball mill for 32 hours, release the slurry, pass through a 180 mesh sieve, and then remove iron to obtain slurry, which is product B;

[0032] ③ Press filter dehydration of product B to make a mud cake with a moisture content of 25%.

Embodiment 3

[0033] Embodiment 3: according to the preparation method of aforementioned environment-friendly chaff ash ceramic billet, make according to the following steps:

[0034] ① Weigh 38 parts of kaolin, 13 parts of feldspar, 29 parts of quartz and 38 parts of chaff ash and mix them to obtain product A;

[0035] ②According to product A: grinding ball: water=1: 1.8: 0.7 weight ratio, put into ball mill and ball mill for 30 hours, let out the slurry, pass through a 180 mesh sieve, and then remove iron to obtain slurry, which is product B;

[0036] ③ Press filter dehydration of product B to make a mud cake with a moisture content of 23%.

[0037] The prepared mud cake is used in the next process after the mud is refined or pulped.

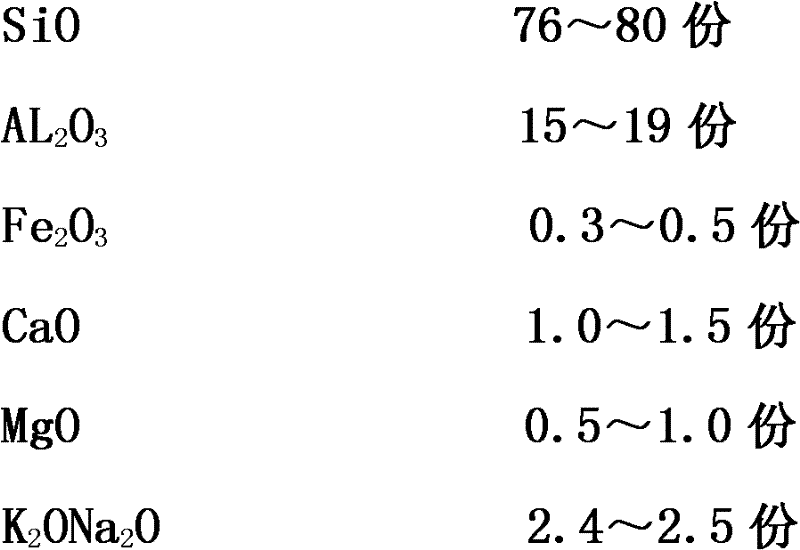

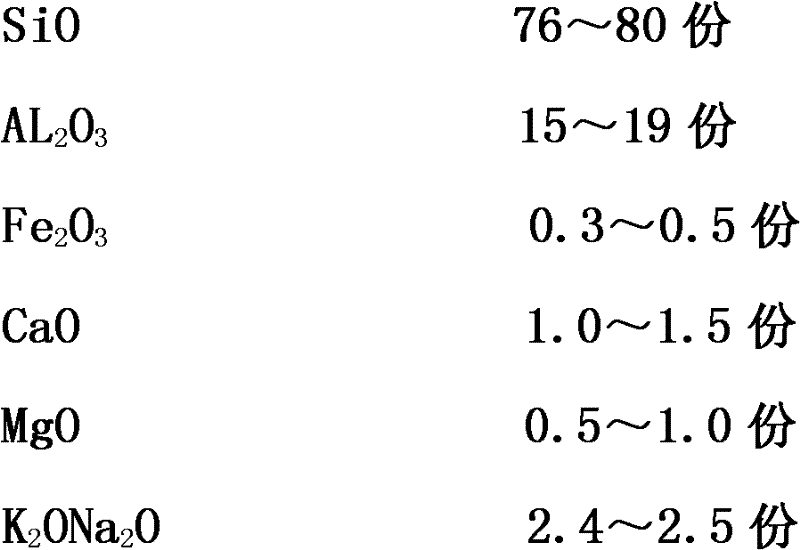

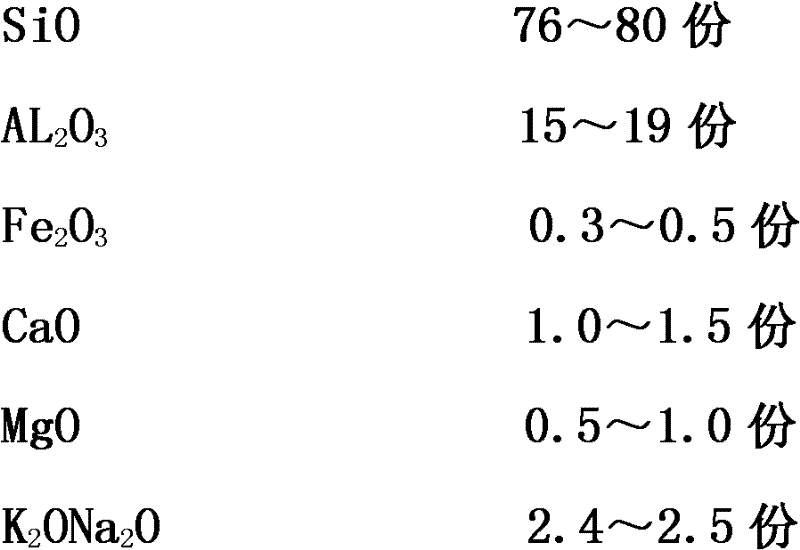

[0038] Four kinds of raw materials of kaolin, feldspar, quartz and chaff ash in the described embodiment can adopt the raw material of following table chemical composition weight percent;

[0039] raw material name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com