Formula of light castables made of fused silica hollow spheres

A lightweight castable, fused silica technology, which is applied in the formulation field of fused silica hollow ball lightweight castables, can solve the problems of no patents and document reports, and achieve good application prospects, good heat insulation effect, and resistance to rapid cooling and rapid heating good sex effect

Active Publication Date: 2012-10-03

洛阳北苑新材料技术有限公司

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Fused silica hollow sphere lightweight castable, as a light heat insulation product, is made of fused silica hollow spheres, and there is no patent or document report yet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

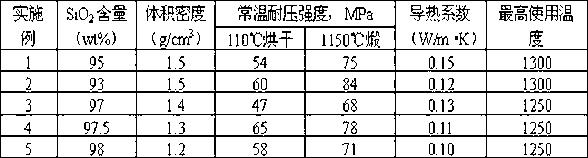

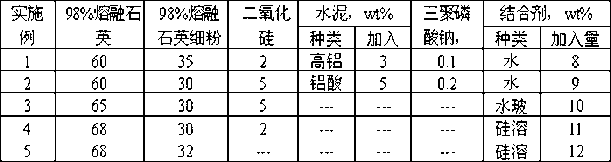

[0028] The proportion of a fused silica hollow sphere castable is shown in Table 1, and the main physical and chemical indicators of the prepared fused silica hollow sphere lightweight castable are shown in Table 2.

[0029] Table 1 Proportion of lightweight castables for fused silica hollow spheres

[0030]

[0031] Table 2 Physical and chemical properties of fused silica hollow sphere lightweight castables

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a formula of light castables made of fused silica hollow spheres. The formula uses the fused silica hollow spheres as aggregates and comprises, by mass, 60-68% of the fused silica hollow spheres, 30-35% of fused silica fine powder, 2-5% of silica micro powder, 0-5% of cement, sodium tripolyphosphate and binding agents, wherein the sodium tripolyphosphate and the binding agents occupy 0-0.2% and 8-12% of the total weight of the fused silica hollow spheres, the fused silica fine powder, the silica micro powder and the cement respectively. The light castables made of the fused silica hollow spheres has the advantages of low volume density, high resistance to thermal shock, high heat insulation performance and chemical stability.

Description

[0001] technical field [0002] The invention relates to the technical field of lightweight fused silica products, in particular to a formulation of a lightweight castable for fused silica hollow spheres. [0003] Background technique [0004] Compared with other refractory insulation materials, fused silica materials, such as SiO 2 The glass ceramics have two remarkable features: 1) The thermal expansion coefficient is very low, its thermal expansion coefficient is only 0.54×10 -6 / °C; 2), the thermal conductivity is very low, and its thermal conductivity is only 2.1W / m·K. Therefore, the fused silica material not only has very good resistance to rapid cooling and heat, but also has very good heat insulation performance. If the fused silica material is processed into a lightweight thermal insulation product, the thermal insulation effect of the lightweight thermal insulation product is unmatched by other refractory lightweight thermal insulation products. [0005] The fu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/26C04B28/24C04B28/06

Inventor 张拯雷复兴孙学义刘广彬

Owner 洛阳北苑新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com