Organic silicon modified acrylic resin antifouling paint and preparation method thereof

A technology of acrylic resin and antifouling paint, applied in antifouling/underwater paint, coating, paint containing biocide, etc., can solve the problems of poor adhesion between antifouling paint and substrate, high toxicity, etc. The effect of marine organisms attaching, enhancing alkalinity, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

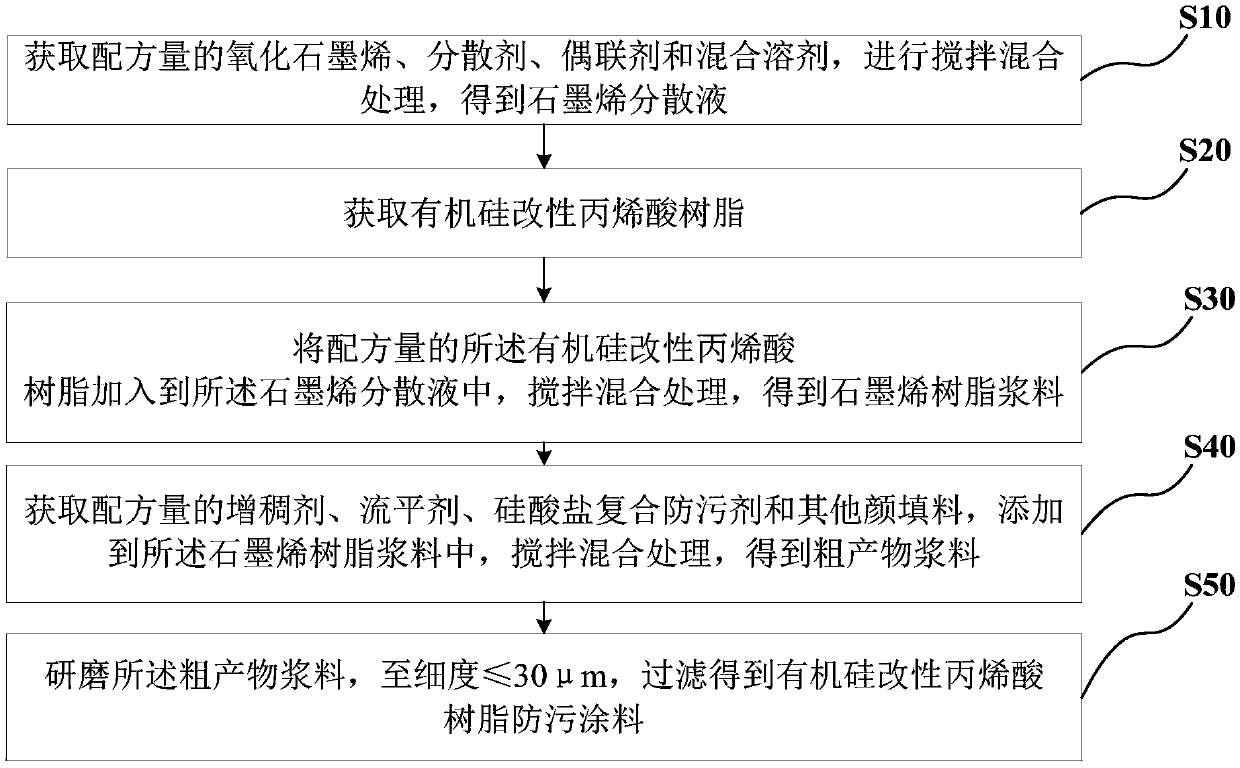

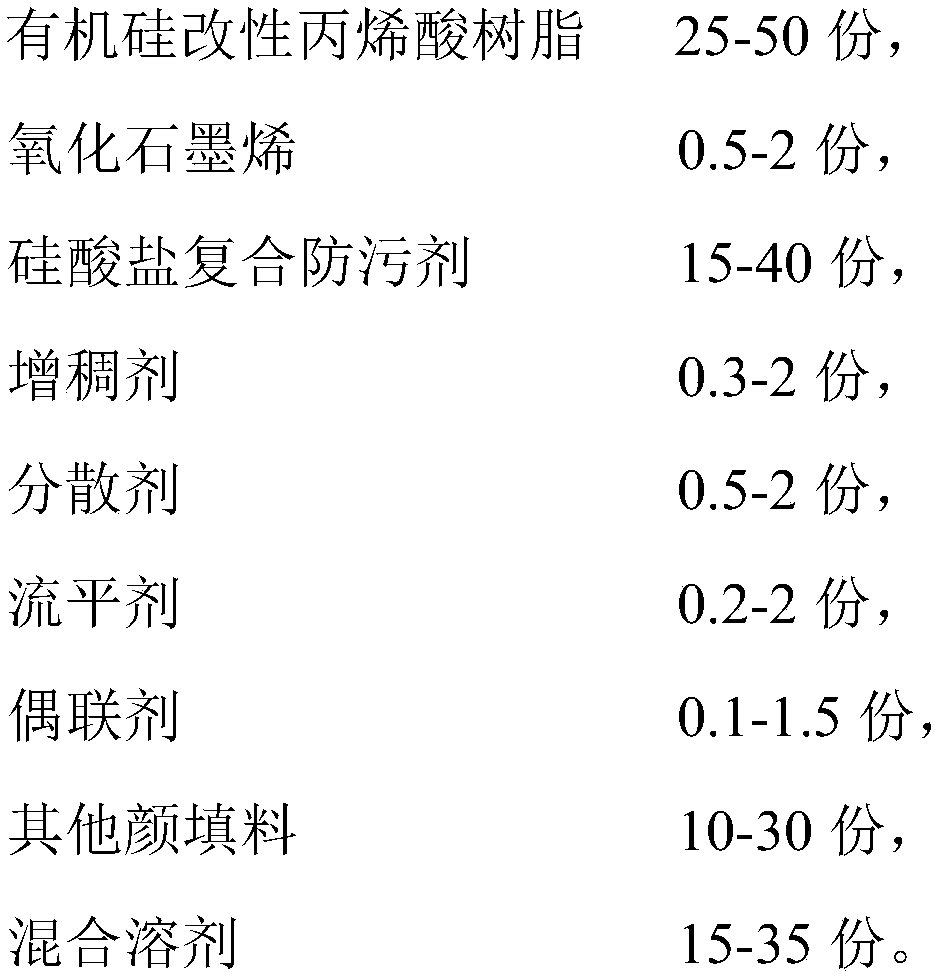

[0057] as attached figure 1 As shown, the preparation method of the silicone-modified acrylic resin antifouling coating described in the embodiments of the present invention may further comprise the steps:

[0058] S10. Obtain the graphene oxide, dispersant, coupling agent and mixed solvent of the formula amount, stir and mix, and obtain the graphene dispersion;

[0059] S20. Obtaining a silicone-modified acrylic resin;

[0060] S30. adding the organosilicon-modified acrylic resin in a formula amount into the graphene dispersion, stirring and mixing to obtain a graphene resin slurry;

[0061] S40. Obtain the thickener, leveling agent, silicate composite antifouling agent and other pigments and fillers of the formula, add them to the graphene resin slurry, stir and mix, and obtain the crude product slurry;

[0062] S50. Grinding the crude product slurry to a fineness of ≤30 μm, and filtering to obtain a silicone-modified acrylic resin antifouling coating.

[0063] The prepar...

Embodiment 1

[0071] A silicone modified acrylic resin antifouling coating.

[0072] S10. Accurately weigh 0.6 parts of graphene oxide, 0.8 parts of dispersant, 0.3 parts of silane coupling agent and mixed solvent (12 parts of xylene and 8 parts of n-butanol), stir and mix, the speed is 500-1000r / min, and the stirring time 15 to 20 minutes to obtain a graphene dispersion;

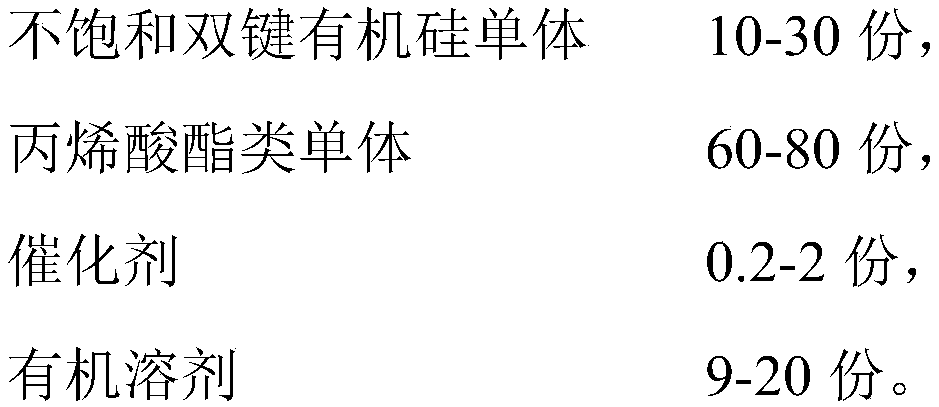

[0073] S20. Accurately weigh 14 parts of unsaturated double-bond silicone monomer, 70 parts of acrylate monomer, and 15 parts of organic solvent. -After dripping within 2 hours, keep warm for another 2-3 hours to obtain a silicone-modified acrylic resin;

[0074] S30. Accurately weigh 38 parts of S20 organosilicon-modified acrylic resin and add them to the S10 graphene dispersion liquid, stir and mix, the stirring speed is 500-2000r / min, and the stirring time is 10-30min, to obtain graphene resin slurry;

[0075] S40. Accurately weigh 0.7 part of thickener organic bentonite, 0.6 part of leveling agent, 21 parts of sili...

Embodiment 2

[0078] A silicone modified acrylic resin antifouling coating.

[0079] S10. Accurately weigh 0.8 parts of graphene oxide, 1 part of dispersant, 0.2 parts of silane coupling agent and mixed solvent (15 parts of xylene and 8 parts of n-butanol), stir and mix, the speed is 500-1000r / min, and the stirring time 15 to 20 minutes to obtain a graphene dispersion;

[0080] S20. Accurately weigh 14 parts of unsaturated double-bond silicone monomer, 70 parts of acrylate monomer, and 15 parts of organic solvent. -After dripping within 2 hours, keep warm for another 2-3 hours to obtain a silicone-modified acrylic resin;

[0081] S30. Accurately weigh 32 parts of S20 organosilicon-modified acrylic resin and add them to the S10 graphene dispersion liquid, stir and mix, the stirring speed is 500-2000r / min, and the stirring time is 10-30min, to obtain the graphene resin slurry;

[0082] S40. Accurately weigh 1 part of thickener fumed silica, 0.5 part of leveling agent, 26 parts of silicate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com