Heat-resisting liquid silicon rubber with improved strength and interface bonding performance

A liquid silicone rubber and interface bonding technology, which is applied in the field of heat-resistant liquid silicone rubber materials to achieve the effects of easy processing, broad market application prospects and high heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the preparation of the liquid silicone rubber of epoxy resin modification of the present invention

[0026] One, the preparation method of the liquid silicone rubber of epoxy resin modification of the present invention

[0027] 1 Experimental raw materials

[0028]

[0029] 2 Preparation of bisphenol A type epoxy resin-silane coupling agent prepolymer

[0030]

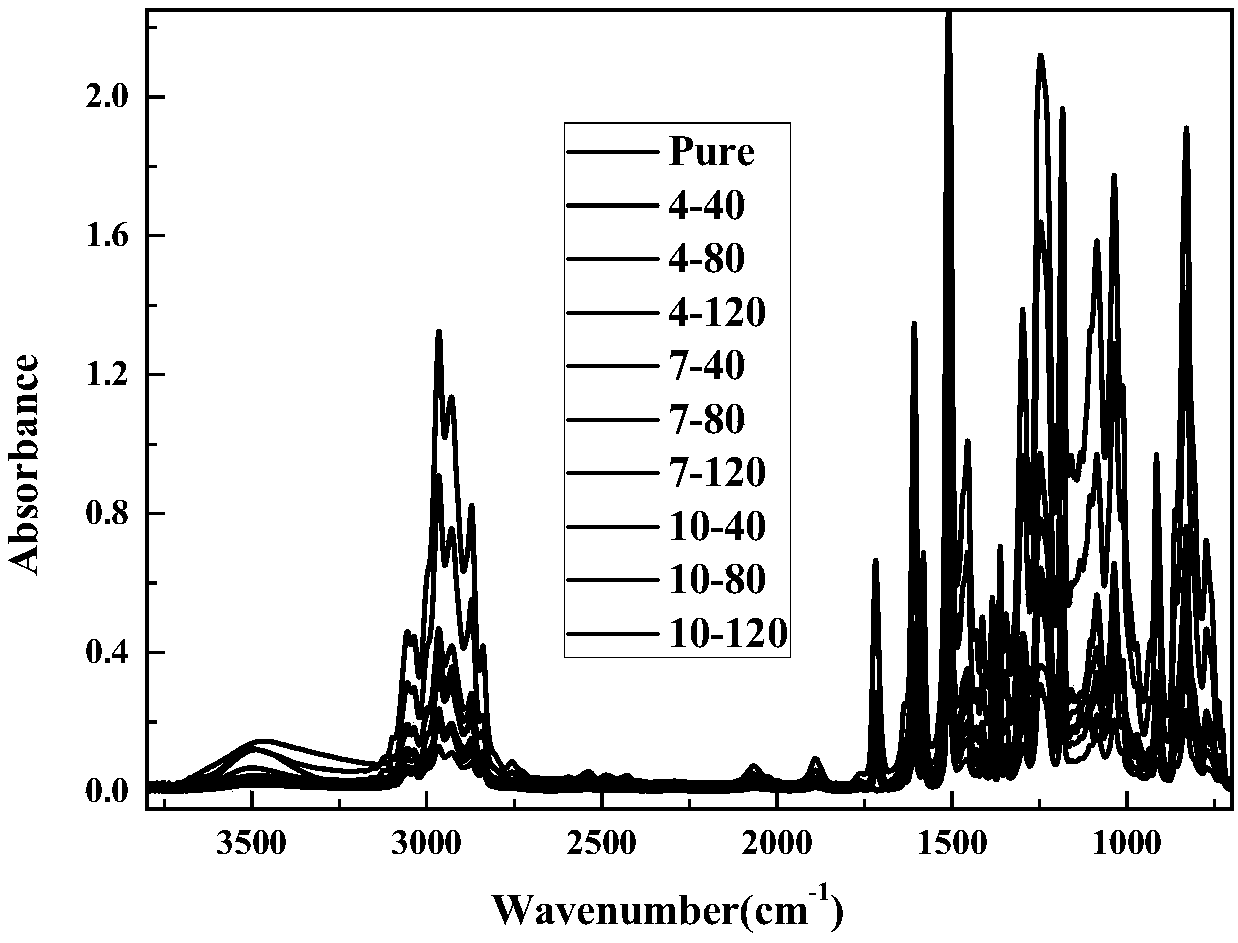

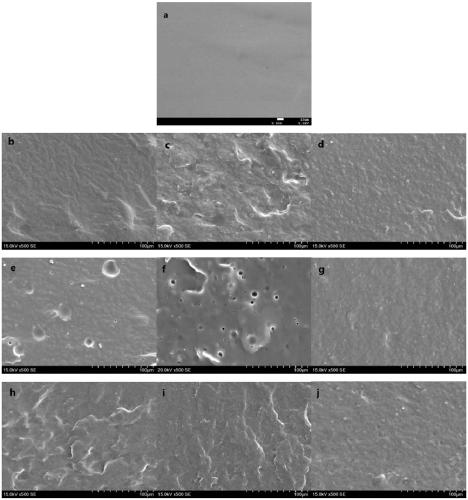

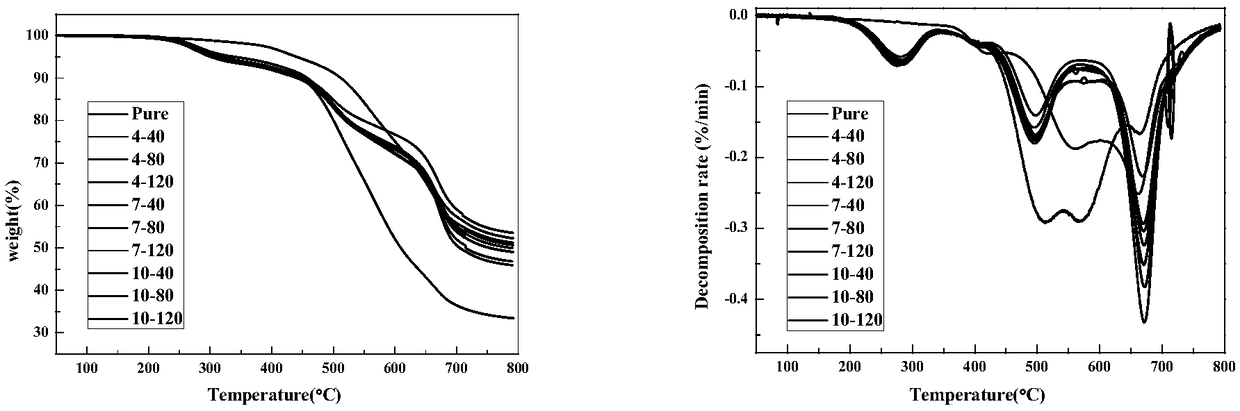

[0031] To a three-necked flask equipped with a thermometer, a mechanical stirrer and a reflux condenser device, an epoxy resin (E44, 50 g) and a silane coupling agent (SCA-L, 13.04 g) were sequentially added in a molar ratio of 1:1 to feed an inert Exhaust the air in the device, raise the temperature to 100°C and keep it constant, start stirring to make the mixture evenly mixed. By changing the time of the prepolymerization reaction and the amount of catalyst (tetraisopropyl titanate) (see Table 1), 9 groups of different primary products were prepared respectively, and the primary products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com