Fibrous filler modified polycarbonate composite and preparation method thereof

A polycarbonate and fibrous technology, applied in the field of modified polymer materials, can solve the problems affecting the service life of composite materials, narrow processing window, high melt strength, etc., to improve processing fluidity, rigidity and toughness, Effect of High Melt Index

Active Publication Date: 2020-06-26

JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, polycarbonate is characterized by high melt strength, and the addition of filler materials will undoubtedly bring a lot of difficulties to the processing of the composition, especially after adding filler materials, it is necessary to increase the processing temperature and increase the shear to obtain Higher melt flow rate to facilitate dispersion of filler material resulting in a narrower processing window

Moreover, the surface characteristics of the filling material lead to the cracking and degradation of the po

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

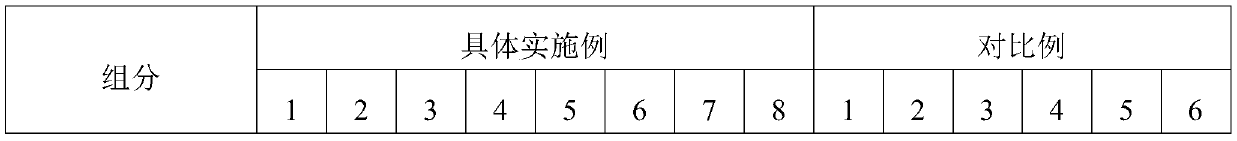

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

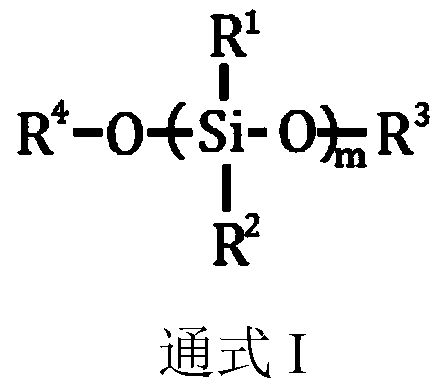

The invention discloses a fibrous filler modified polycarbonate composite and a preparation method thereof. The composite comprises first polycarbonate, second polycarbonate, a fibrous filler and a dispersing agent. The specific dispersing agent and the second polycarbonate are used in a conventional fibrous filler modified polycarbonate system in a matched manner; by utilizing the dispersing agent of which one molecular chain contains two different types of functional groups at the same time, the interface action and dispersion of the filler in the material can be controlled, so that the rigidity and toughness of the material are further improved at the same time; by utilizing the branched polycarbonate with specific branching degree, the dispersion of the fibrous filler in the resin canbe improved, and the processing fluidity of the composite can also be improved, so that the composite has higher melt index and is particularly suitable for preparing thin-wall products.

Description

technical field [0001] The invention relates to a polycarbonate compound and a preparation method thereof, in particular to a glass fiber modified polycarbonate compound and a preparation method thereof, belonging to the technical field of modified polymer materials. Background technique [0002] Polycarbonate is an engineering plastic with excellent performance. It has good comprehensive properties, such as high mechanical strength, good impact toughness, dimensional stability, and good electrical insulation. Therefore, it is widely used in the preparation of various industrial and civil parts. , such as various transparent devices, lampshades, instrument panels, etc. But at the same time, polycarbonate also has the problems of high melt viscosity, poor fluidity, and poor solvent resistance, and it is prone to stress cracking and swelling in solvents and alkaline environments, and is more sensitive to notches, and it is prone to stress cracking during processing. , and the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L69/00C08K7/14C08K5/5435C08K5/5419C08K5/134C08K13/04C08J5/04

CPCC08J5/043C08J2369/00C08J2469/00C08K7/14C08K5/5435C08K5/5419C08K5/1345C08K13/04

Inventor 刘贤文岑茵田征宇董相茂张永

Owner JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com