Wafer-level packaging method of image sensor chips

An image sensor and wafer-level packaging technology, applied in the semiconductor field, can solve problems such as fragile, dust pollution, and increase packaging costs, and achieve the effects of avoiding cutting, high reliability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

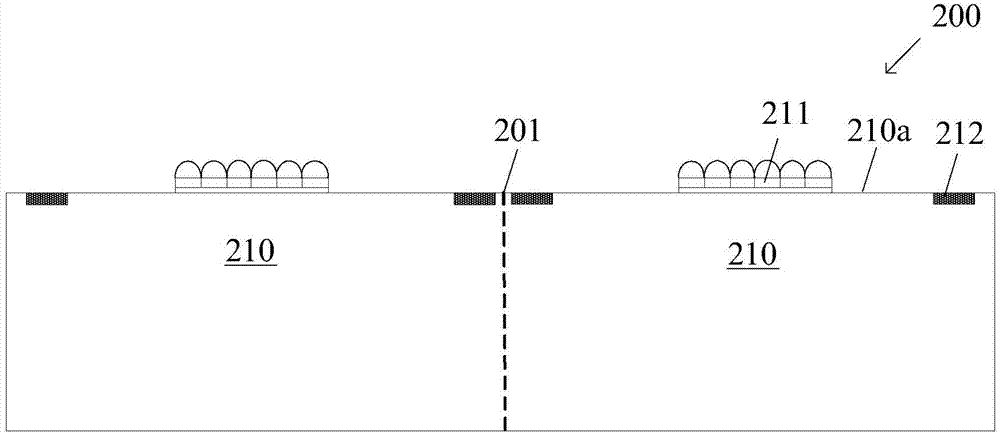

[0097] In the wafer-level packaging method of the image sensor chip provided in the second embodiment, a wafer, a mixed substrate and a carrier are also provided, and the wafer, the mixed substrate and the carrier can refer to the related content of the first embodiment, and, In this embodiment, similarly, the wafer, the hybrid substrate and the carrier are sequentially stacked and bonded together.

[0098] Same as the first embodiment, in this embodiment, the hybrid substrate and the carrier board are fixed together by spot glue. However, different from Embodiment 1, in this embodiment, after the redistribution line process and solder bump manufacturing process are performed on the wafer, and before the wafer and the mixed substrate are cut along the dicing line, the viscosity of the dispensing glue is reduced. In particular, the carrier is separated from the hybrid substrate, after which the wafer and hybrid substrate are diced.

[0099] Since this embodiment does not cut t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com