Operating device for printing machine

A technology for printing images and camera devices, which is applied to printing machines, general parts of printing machinery, printing, etc., and can solve problems such as incorrect operation of the placed surface and incorrect recognition of the camera

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

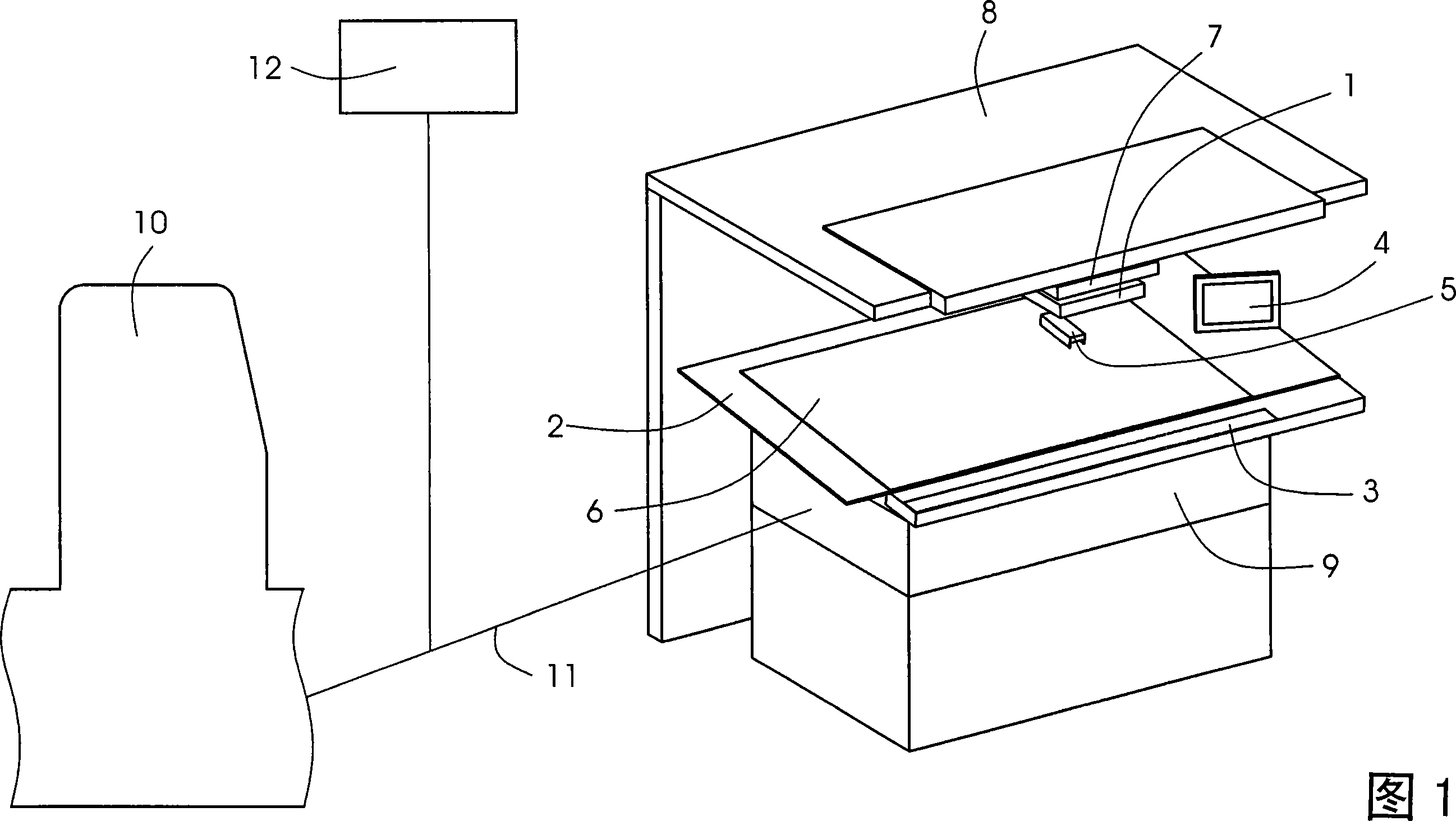

[0021]FIG. 1 shows a control table 8 which has a deposit table 2 for depositing printing materials 6 in the form of sheets. The placing table 2 is inclined slightly forward so that the operator has a good view of the placed sheets 6 . A screen 4 is located in the right area, which is designed as a touch screen and can display and input operating data. This screen 4 is connected to a computer 9 which is located in the lower area of the operating table 8 below the placement table 2 . The computer 9 can communicate with the machine computer of the printing press 10 and with the computer of the pre-printing stage 12 via a communication link 11 . Data from the pre-printing stage 12 and data from the printing press 10 can thus be displayed on the screen 4 . In addition, adjustments to the printing press 10 can also be made via the screen 4 , as well as, for example, during the exposure of the printing plates of the printing stage 12 . Furthermore, the computer 9 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com