Automatic conveying, taking and supplying system for battery piece baskets

A feeding system and cell technology, applied in the direction of charge manipulation, conveyor objects, furnaces, etc., can solve the problems of increasing production costs, inconvenience, and damage to solar cells, so as to improve work efficiency, avoid damage, and save energy. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

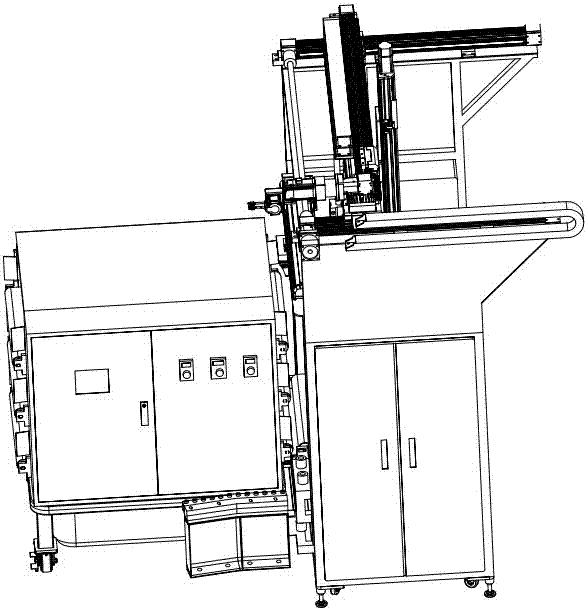

[0022] Such as figure 1 As shown, the present invention is an automatic transfer, retrieving and feeding system for cell flower baskets, including a transfer mechanism, a retrieving mechanism, and a feeding mechanism.

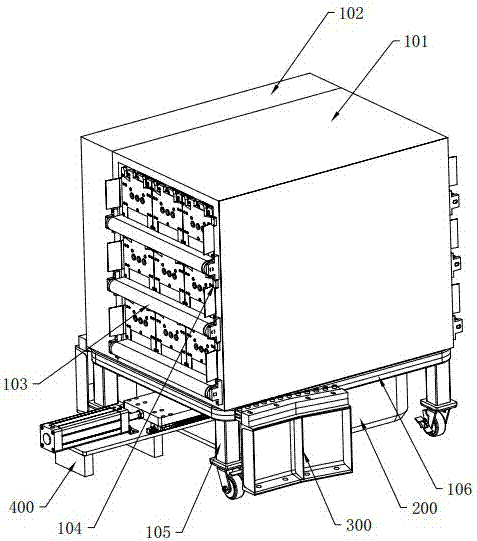

[0023] Such as figure 2 As shown, the transmission mechanism includes a silo, an AGV trolley 200, and a positioning mechanism. The silo includes a silo main body 101 and a universal wheel support frame 105 for supporting the silo main body 101. The silo is provided with three layers of storage Space, the bottom of each storage space is equipped with electric roller conveyor belt Ⅰ103, and the electric roller can rotate in the forward and rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com