Label paper cutting equipment

A technology of cutting equipment and label paper, applied in metal processing and other directions, can solve the problems of complicated operation process, complicated rotation process of rotating parts, and large labor consumption, etc., to achieve the effect of convenient operation and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

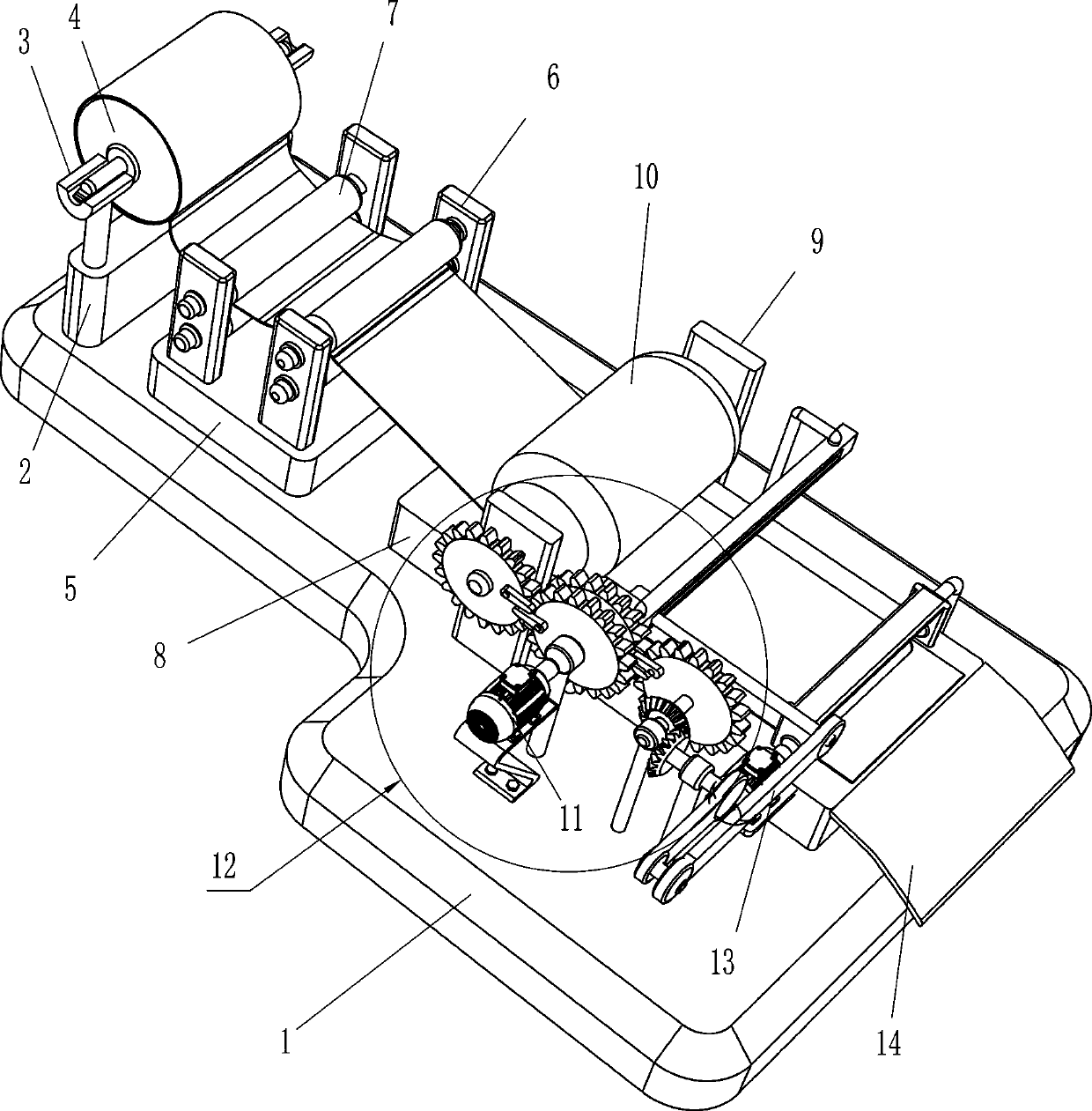

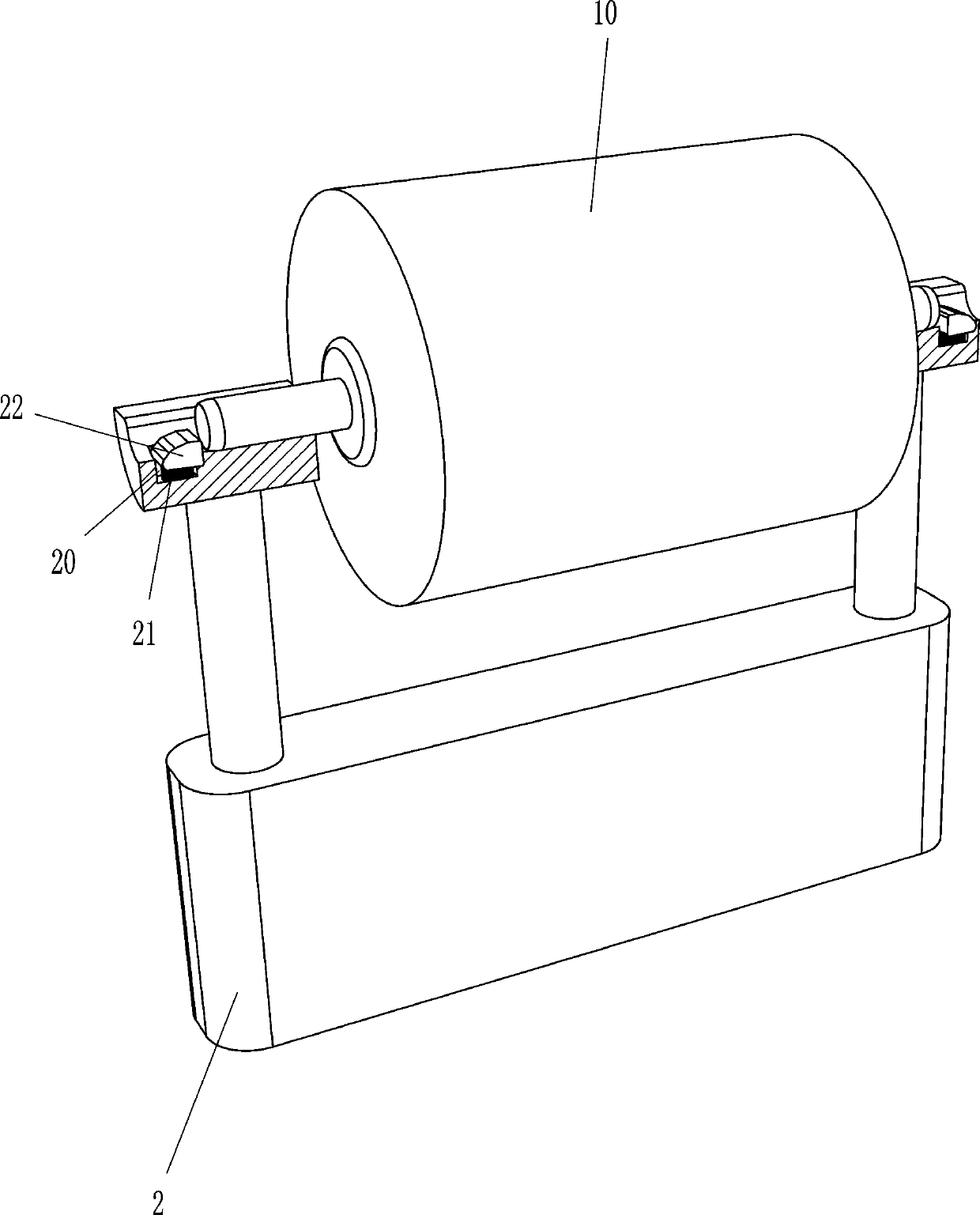

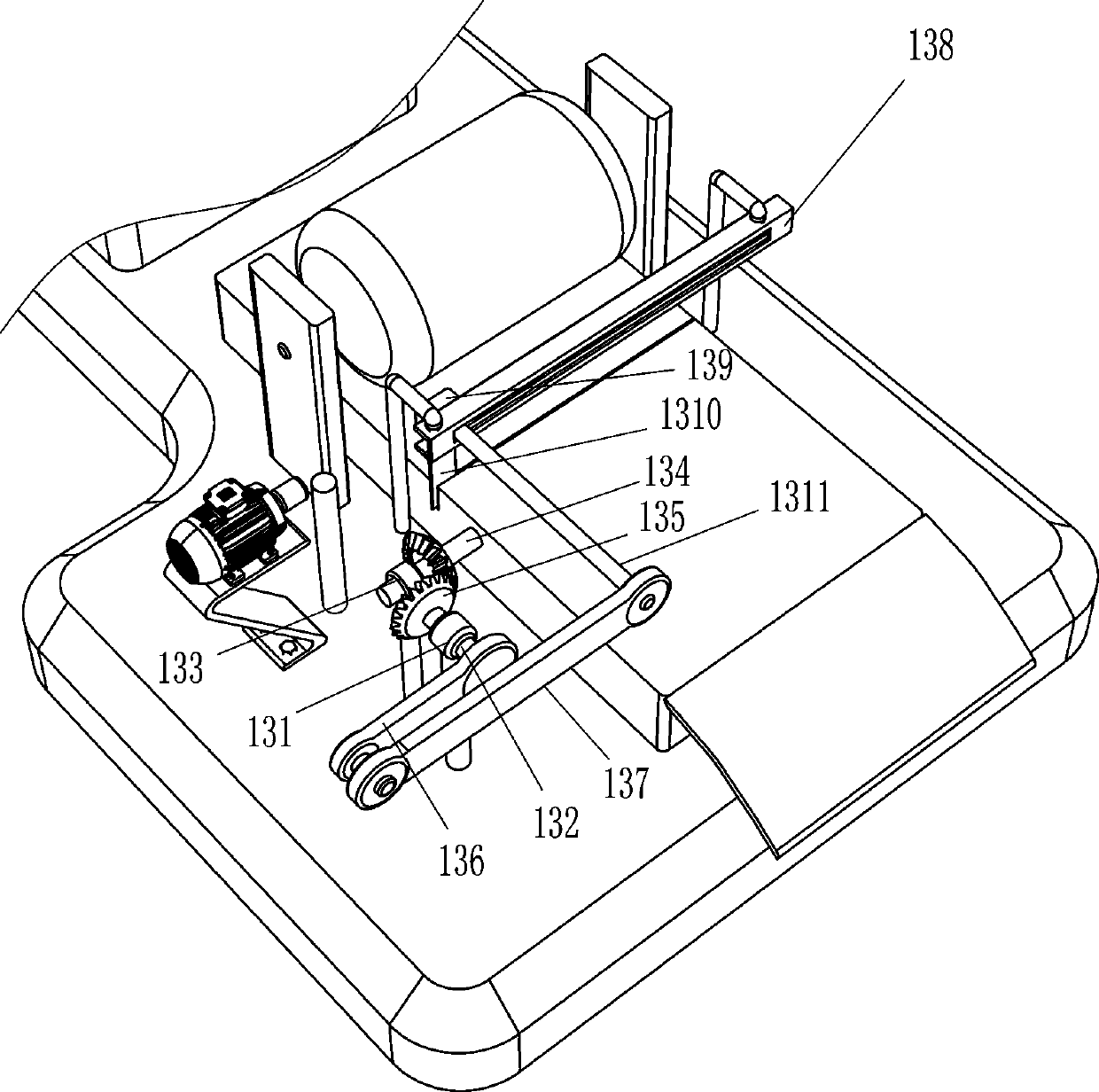

[0022] like Figure 1-5 As shown, a label paper cutting equipment includes a bottom plate 1, a fixed seat 2, a half-ring placement block 3, a roll material drum 4, a mounting seat 5, a mounting frame 6, a transmission roller 7, a workbench 8, and a first bearing seat 9. Rolling cylinder 10, servo motor 11, intermittent transmission mechanism 12 and cutting mechanism 13, the top left side of the bottom plate 1 is provided with a fixed seat 2 and a mounting seat 5, the mounting seat 5 is located on the right side of the fixed seat 2, and the front and back of the fixed seat 2 are symmetrical A half-ring placement block 3 is provided, and the two half-ring placement blocks 3 are used to place the roll material cylinder 4. Two mounting frames 6 are symmetrically arranged on the front and rear sides of the top of the mounting seat 5, and the mounting frames 6 on the front and rear sides are all rotatable. Two drive rollers 7 are provided, a workbench 8 is provided on the top right ...

Embodiment 2

[0027] On the basis of Example 1, such as Figure 1-5 As shown, it also includes a slide plate 14, an N-shaped frame 15, a rotating shaft 16, a rolling roller 17, a rotating motor 18 and a button 19, the right side of the workbench 8 is provided with a slide plate 14, and the right side of the bottom plate 1 is provided with an N-shaped frame 15 , the N-shaped frame 15 is located directly above the workbench 8, the N-shaped frame 15 is rotatably provided with a rotating shaft 16, the rotating shaft 16 is provided with a rolling roller 17, and the right part of the front side of the bottom plate 1 is provided with a rotating motor 18, and the rotating motor 18 The output shaft and the front end of the rotating shaft 16 are connected by coupling transmission, and the front and rear sides in the slide rail 138 are all provided with buttons 19, and the buttons 19 are connected with the rotary motor 18 by lines. When the slider 139 drives the cutting knife 1310 to move backward to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com