Combined device for drying sludge and sludge drying method thereof

A combined device and sludge drying technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of increasing process complexity, energy consumption, and long drying process. , consumption of large energy and other issues, to achieve the effect of eliminating the need for conveying equipment or devices, smooth drying process, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

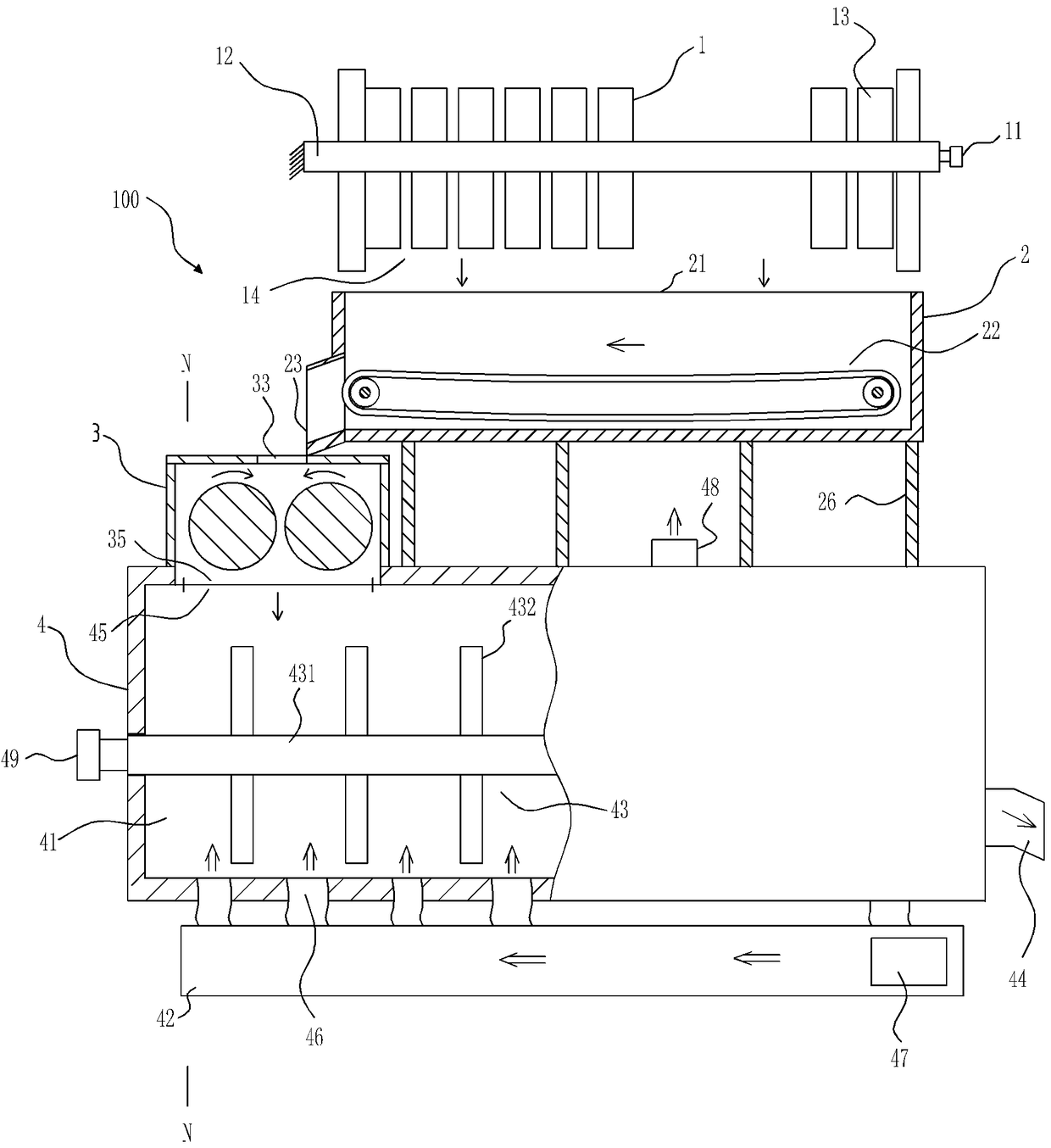

[0016] The following description is merely exemplary in nature and is in no way intended to limit the invention, its application or uses.

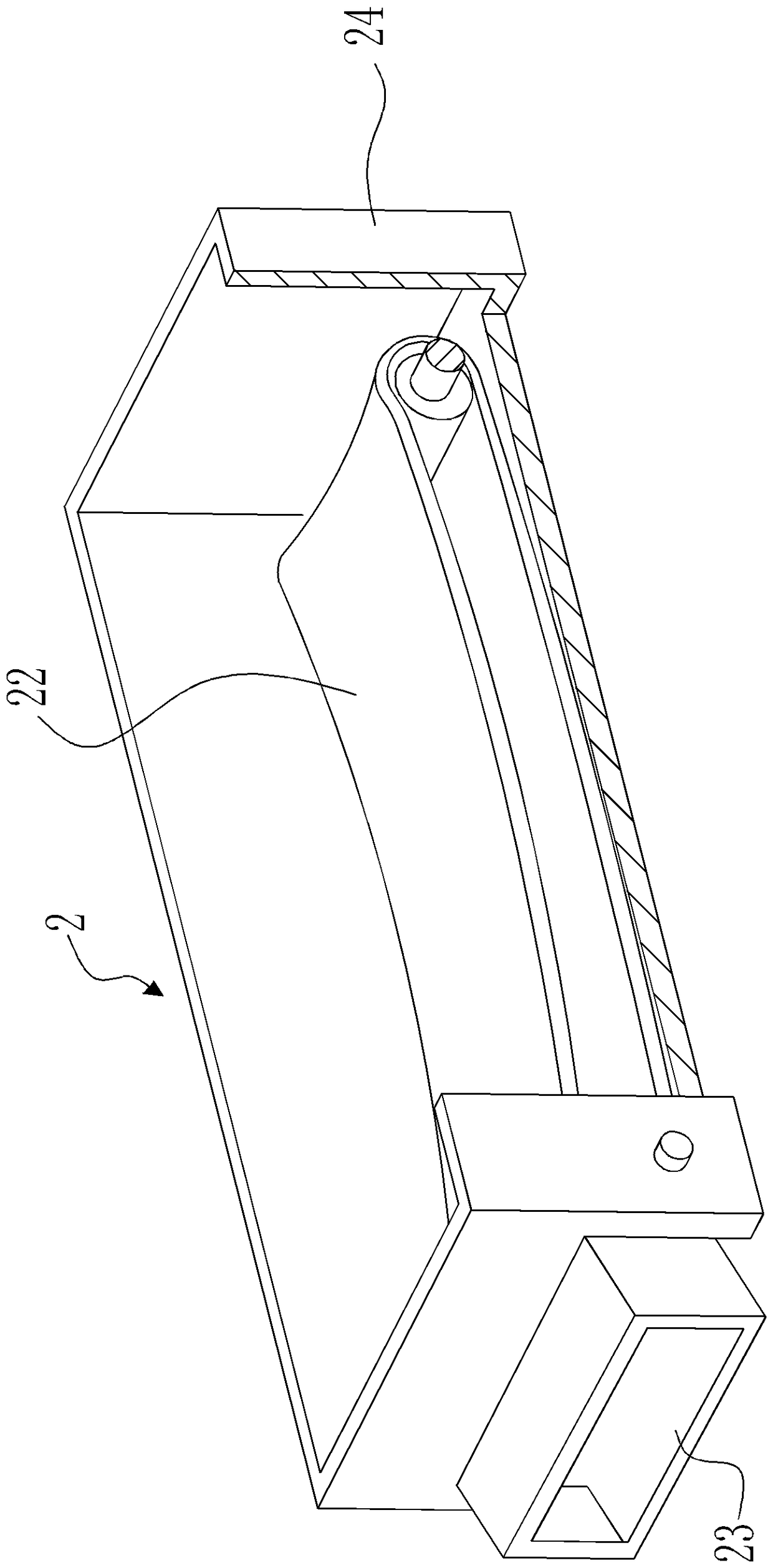

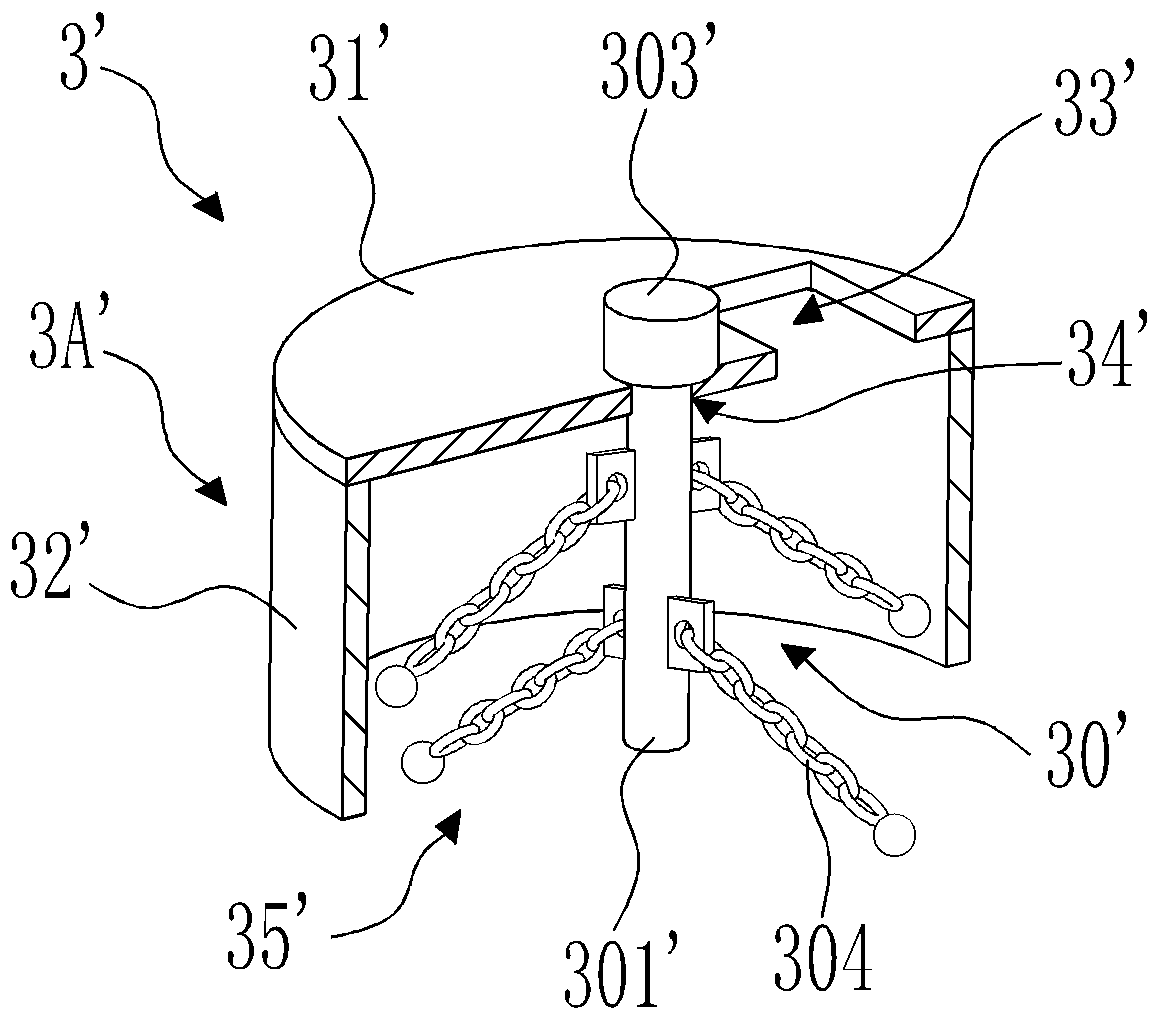

[0017] figure 1 A preferred embodiment of a combined device (or device combination) 100 for sludge drying according to the present invention is shown in a perspective view. The combined device 100 generally includes a dehydration unit, a conveying adjustment unit, a crushing unit and a drying unit. The dehydration unit, the conveying adjustment unit, the crushing unit and the drying unit are generally arranged vertically together, wherein the dehydration unit is arranged at the upper part of the combined device 100, the drying unit is at the lower part thereof, and the conveying adjustment unit and the crushing unit are arranged at the dehydration unit. Between the unit and the drying unit, but the position of the conveying adjustment unit is generally higher than the crushing unit. Generally, the sludge drying process is to turn liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com