Pneumatic quick swing type workpiece transfer device

A pneumatic and fast technology, applied in the direction of conveyor objects, transportation and packaging, which can solve problems such as accelerated wear of hinge points, limited rotation speed of four-bar linkage, structural damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

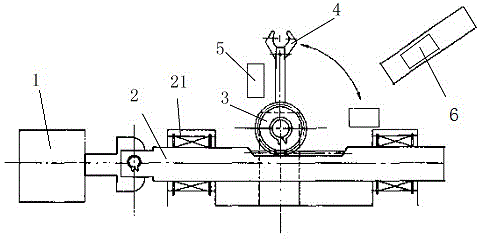

[0011] like figure 1 As shown, the electromagnetic fast swing back device of the present invention, the cylinder 1 and the support, and the cylinder 1 and a rack 2 are riveted together. The tooth bar 2 is fixed on the support by the guide bearing 21, and a gear 3 is meshed on the tooth bar 2, and the rotating shaft of the gear 3 is hinged on the support, and the bar head of the jaw 4 is fixed on the gear 3.

[0012] When in use, due to the use of the cylinder 1 as the power device, the expansion and contraction of the piston rod of the cylinder 1 drives the rack 2 to move back and forth on the support, because a gear 3 is engaged on the rack 2, and the rotating shaft of the gear 3 is hinged on the support. In this way, driven by the reciprocating motion of the rack 2, the fixed jaw 4 on the gear 3 will swing around the gear 3, and can freely move between the feeding position of the workpiece 5 and the discharging position of the workpiece 5. swing. Moreover, the expansion an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com