Device and method for harness wire transferring

A technology of rotary drive device and heald, applied in healds, textiles and auxiliary equipment for papermaking and weaving, etc., can solve the problems of low degree of automation and low efficiency, and achieve the effect of high degree of automation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

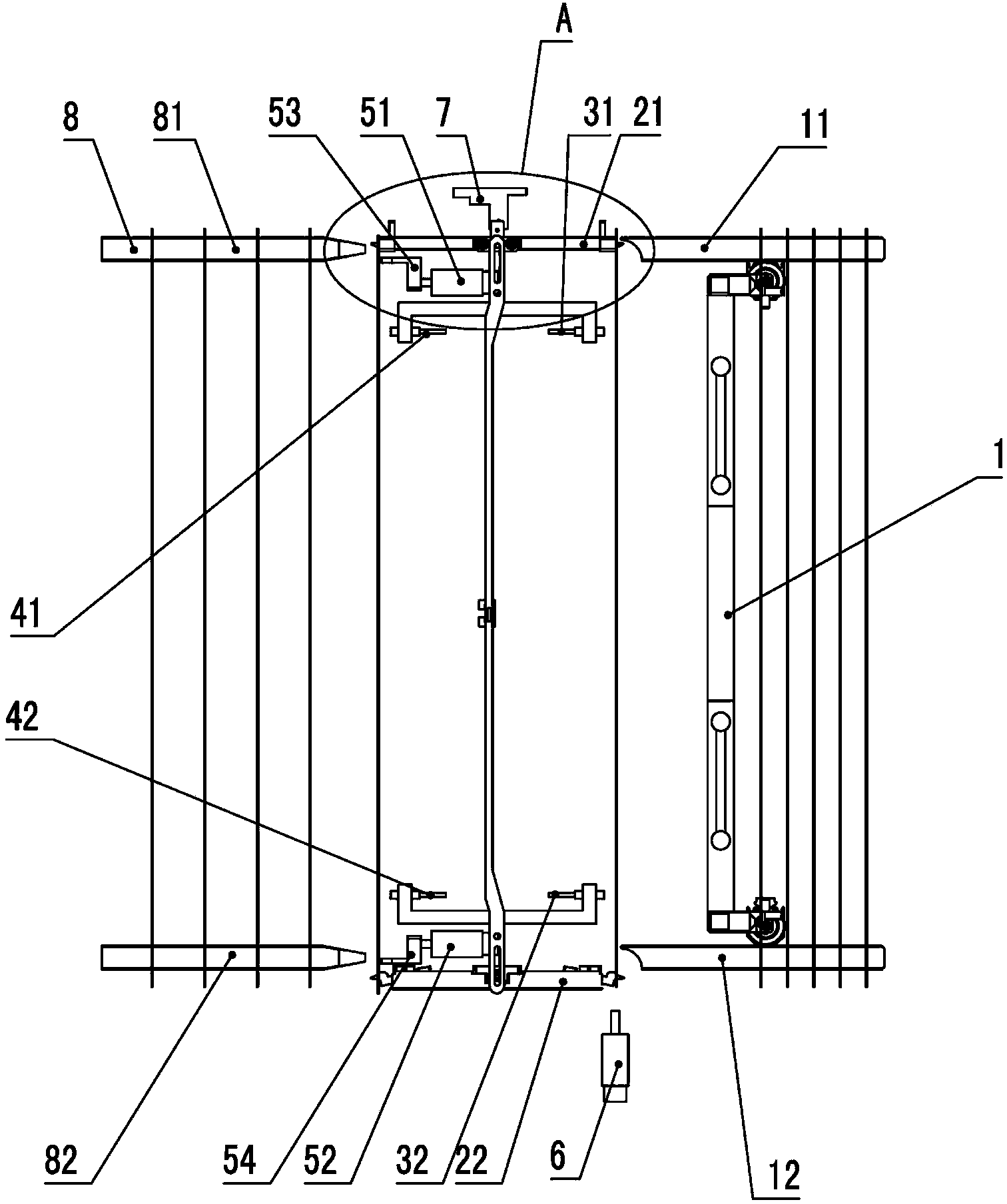

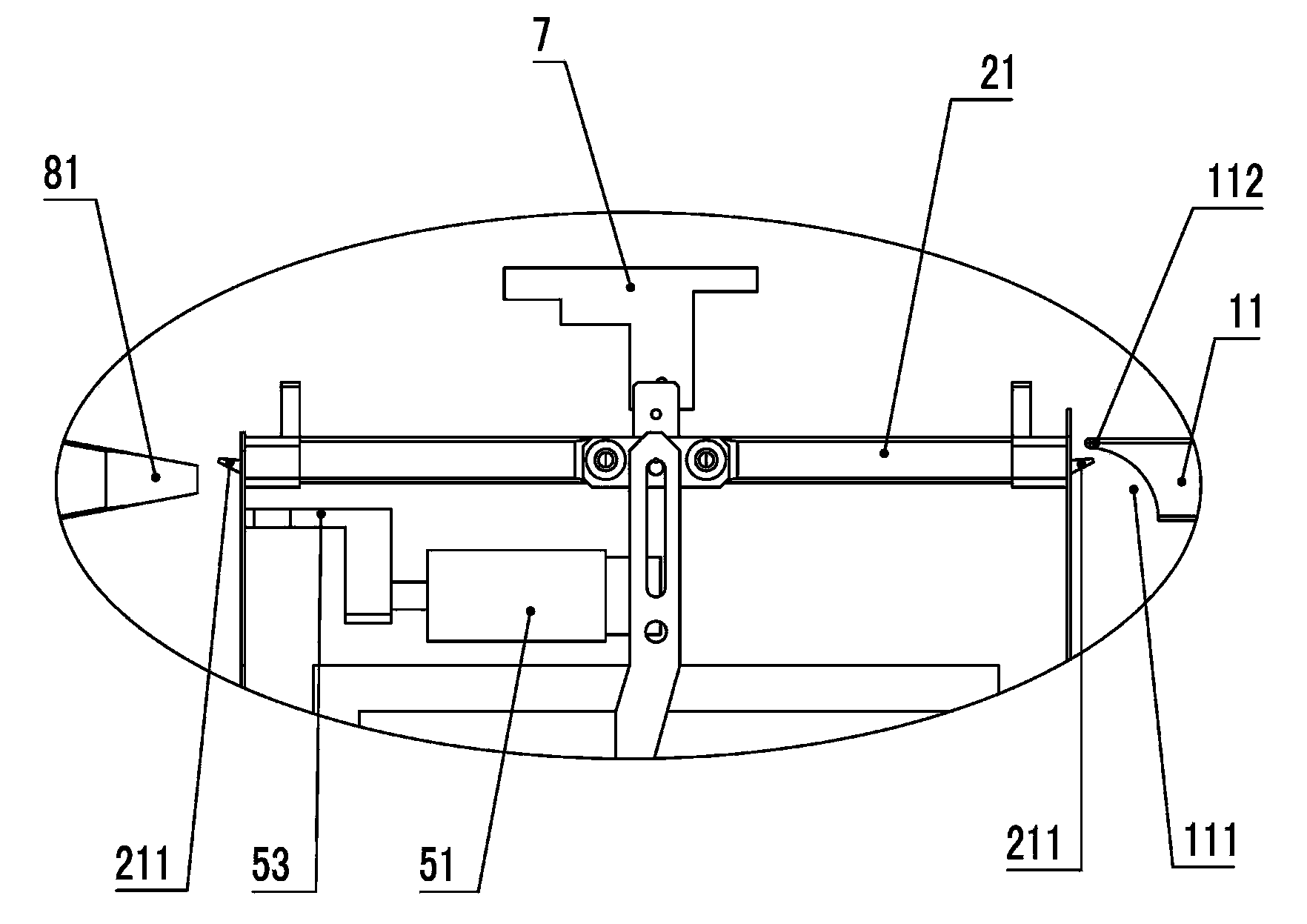

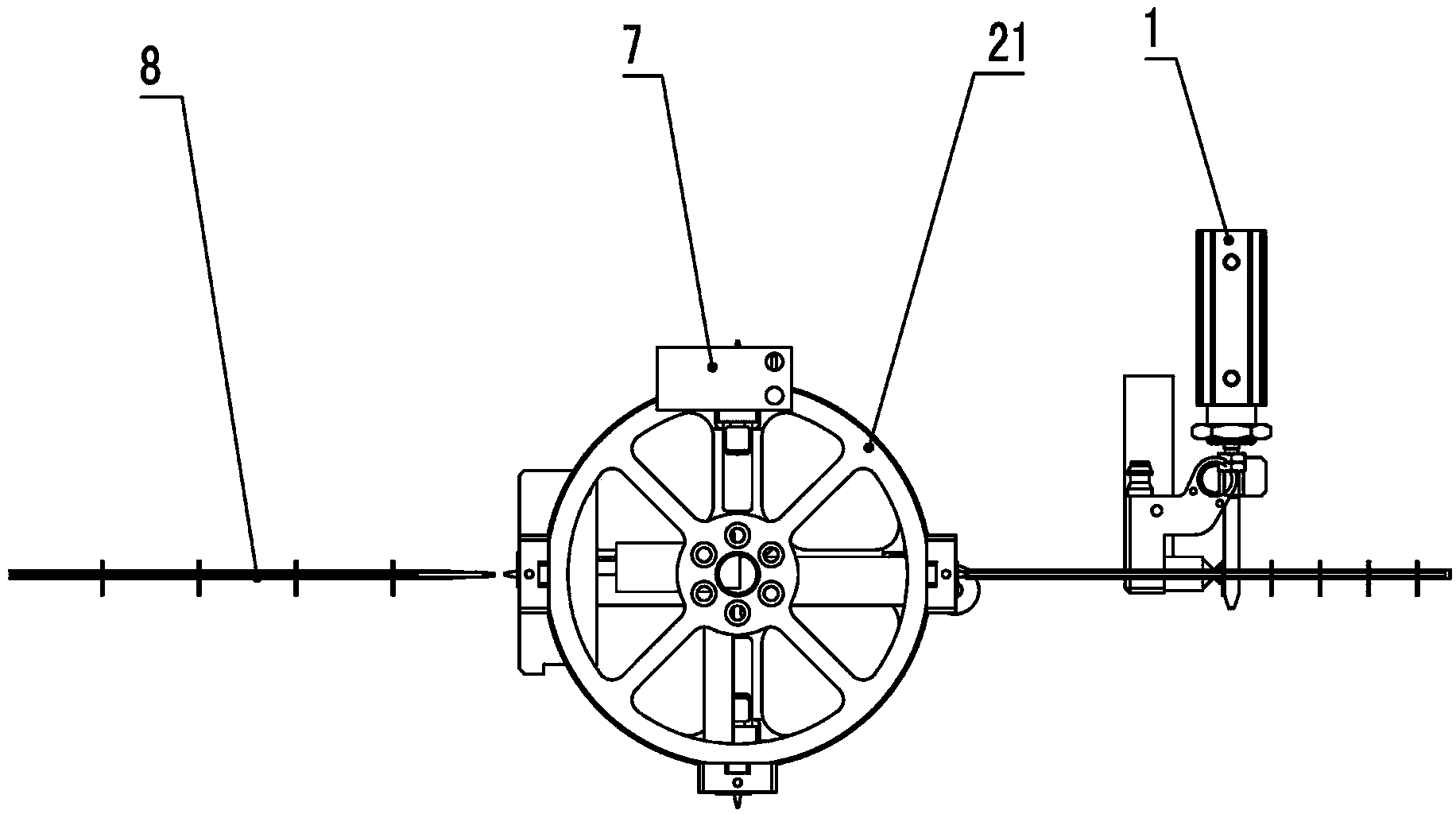

[0031] Figure 1 to Figure 7 The reference numbers in the figure are: heddle separation and conveying device 1; upper stringer 11; upper arc avoidance gap 111; ;; Upper turntable 21; Upper support rod 211; Lower turntable 22; Lower support rod 221; Upper feed detection device 31; Lower feed detection device 32; Upper discharge detection device 41; Bottom discharge detection device 42; upper push cylinder 51; lower push cylinder 52; upper push rod 53; lower push rod 54; elastic rotation tension mechanism 6; spring 61; top tight cylinder 62; distance sensor 7; ; Out of the heald rod 81; out of the heald rod 82; heald element 9; on the perforation 91;

[0032] Such as Figure 1 to Figure 7 As shown, a device for heald transfer includes a base and a controller, the base is provided with a rotary drive device, a coaxially installed upper turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com