Microporous polyethylene film having excellent physical properties, productivity, and quality consistency, and method of producing same

a technology of microporous polyethylene and physical properties, which is applied in the direction of cell components, cell component details, synthetic resin layered products, etc., can solve the problems of different transverse stretching ratios, patents that do not disclose characteristics, and do not use stretching processes, etc., to ensure the stability of a battery and excellent physical properties. , the effect of excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0087] High density polyethylene having a weight average molecular weight of 2.2×105 was used as component I. A paraffin oil having a kinetic viscosity of 110 at 40° C. was used as component II. Contents of components I and II were 30 wt % and 70 wt %, respectively.

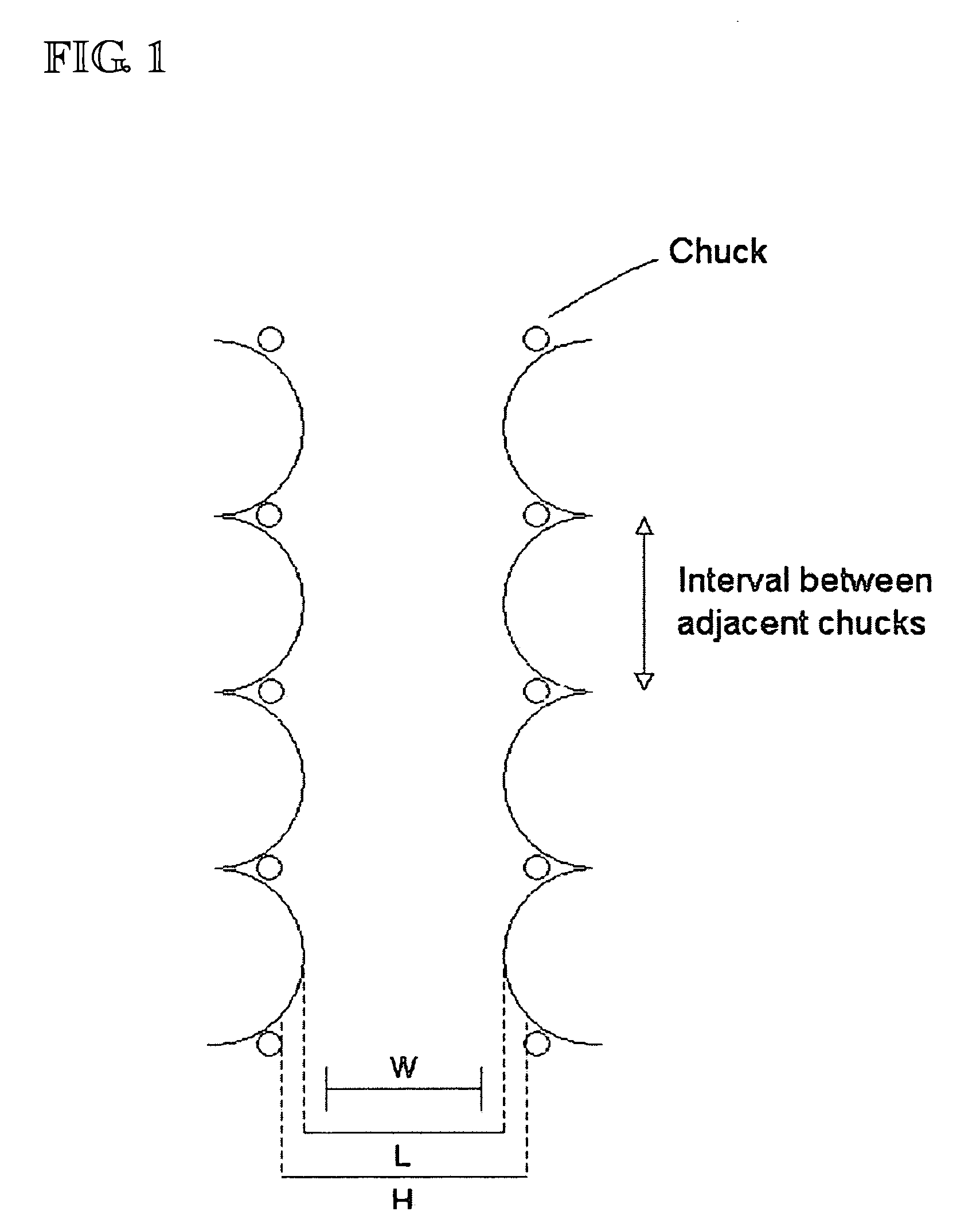

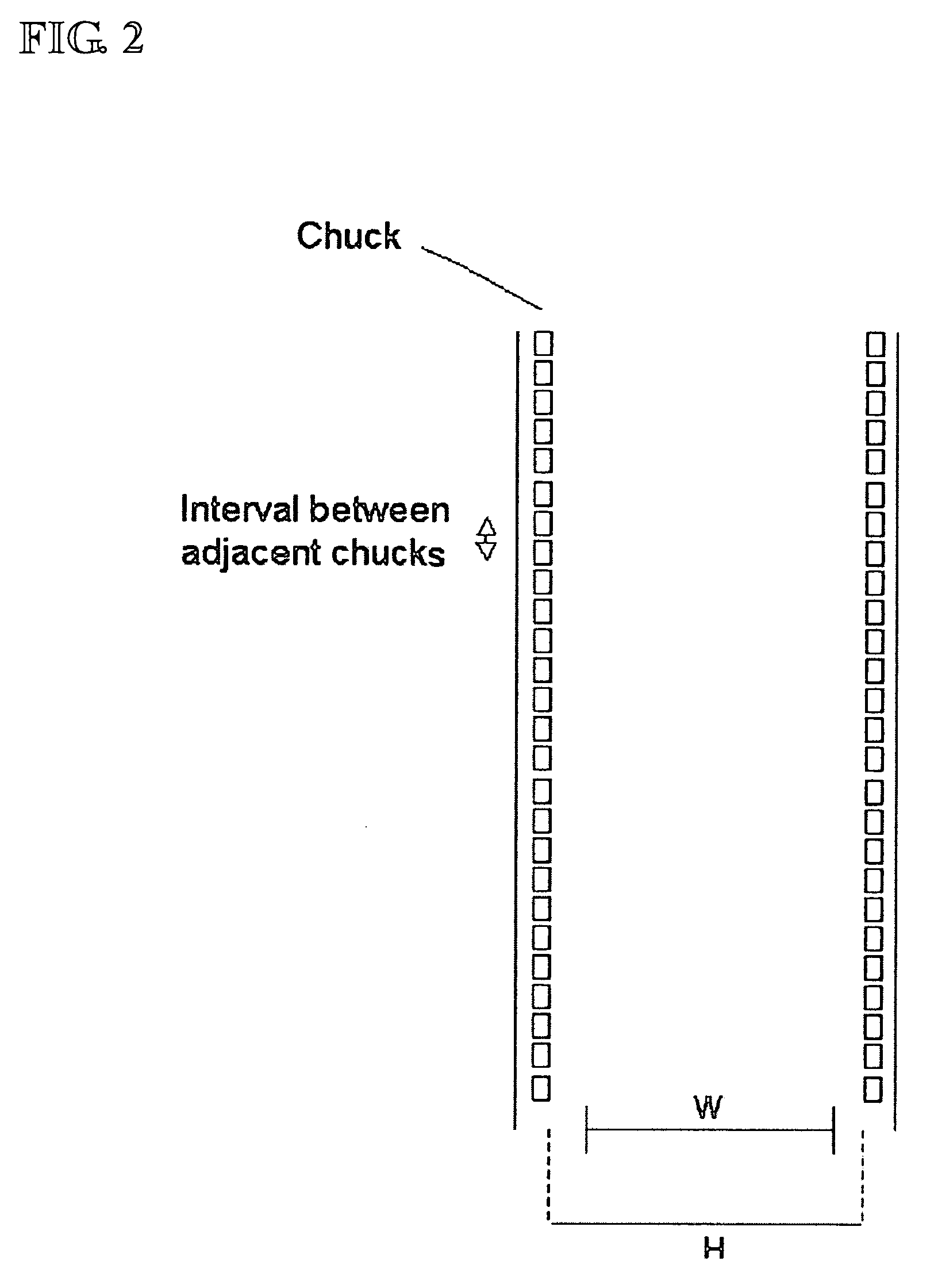

[0088] Stretching was conducted in machine and transverse directions at 118 and 119° C. which corresponded to temperatures at which 50 wt % of a crystalline portion of polyethylene was melted so that machine and transverse direction stretching ratios were 6.1 times and 6 times, respectively. The number of stretching rolls which were used to conduct the stretching in the machine direction was 5. Stretching speed ratios (speed ratio between the adjacent rolls in the front and the rear) of the stretching rolls were set at 1.2-1.5-1.5-1.5-1.5 times. In this case, the speeds of the rolls were increased to be approximately 1.2-1.8-2.74.1-6.1 m / min. Surfaces of the stretching rolls were all coated with chromium so as to have ro...

example 2

[0089] High density polyethylene having a weight average molecular weight of 4.7×105 was used as component I. The remaining conditions were the same as those of example 1.

example 3

[0090] High density polyethylene having a weight average molecular weight of 3.5×105 was used as component I. Contents of components I and II were 10 wt % and 90 wt %, respectively. The remaining conditions were the same as those of example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com