Large free-form surface robot polishing system

A robot and industrial robot technology, applied in the direction of grinding machines, grinding racks, grinding beds, etc., can solve the environment where there is no perfect robot intelligent grinding system solution, grinding pressure and grinding path are difficult to maintain uniformity, and grinding and polishing environment Bad problems, to achieve the effect of ensuring the consistency of grinding quality, ensuring the amount of grinding removal, and realizing real-time communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

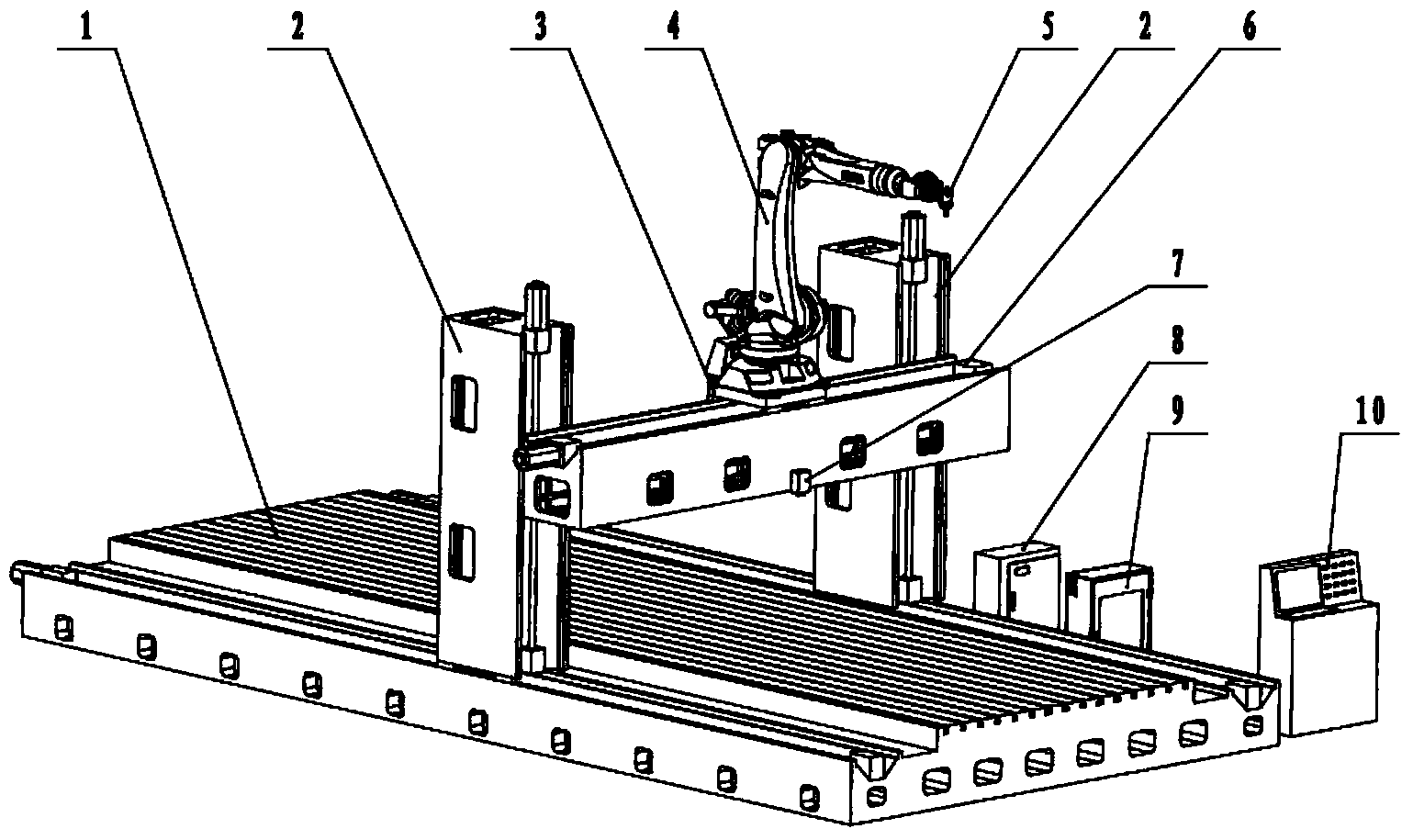

[0022] The invention proposes a large-scale free-form surface robot grinding system, which can realize grinding of large-scale free-form surface parts or batch grinding of multiple parts of the same type by integrating industrial robots, mobile gantry frames and pneumatic grinding heads. Effectively improve production efficiency.

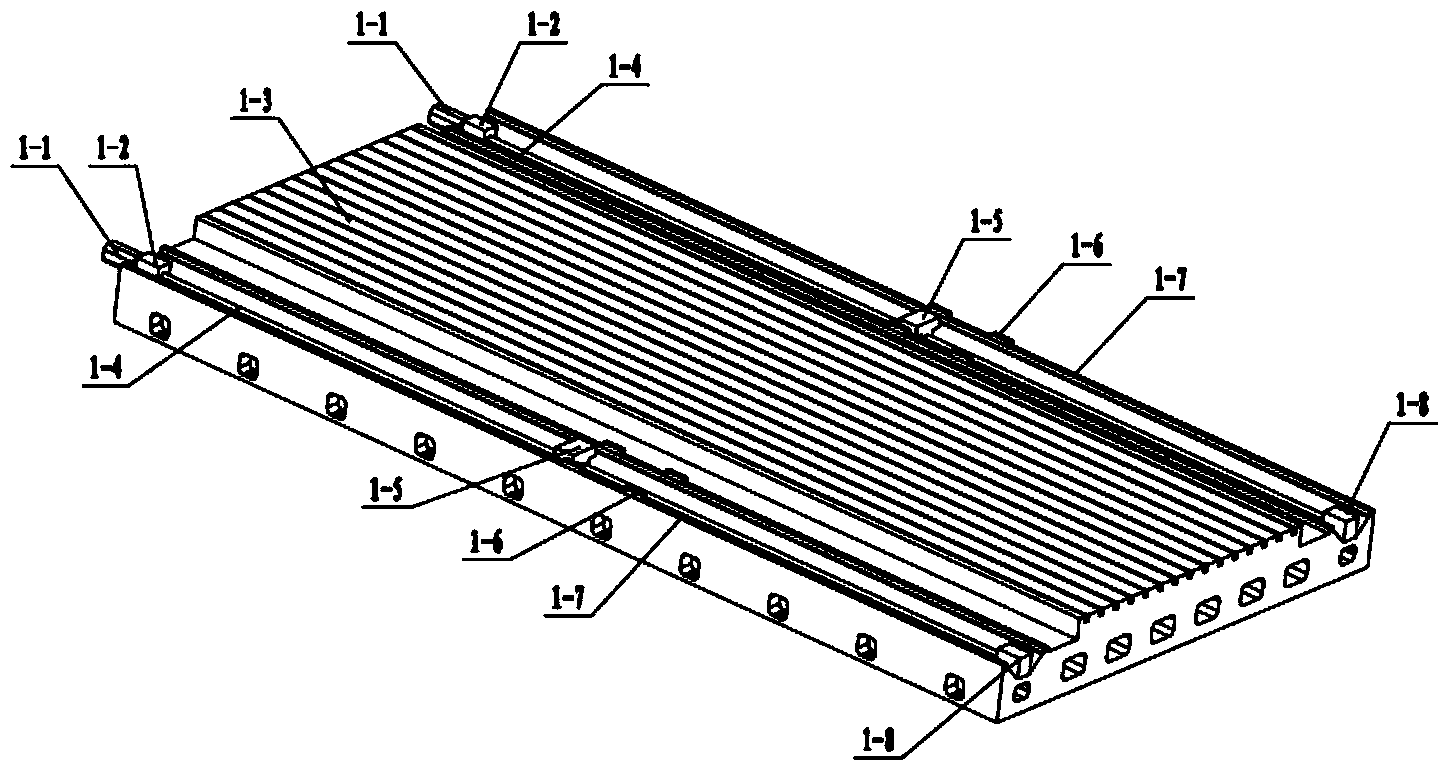

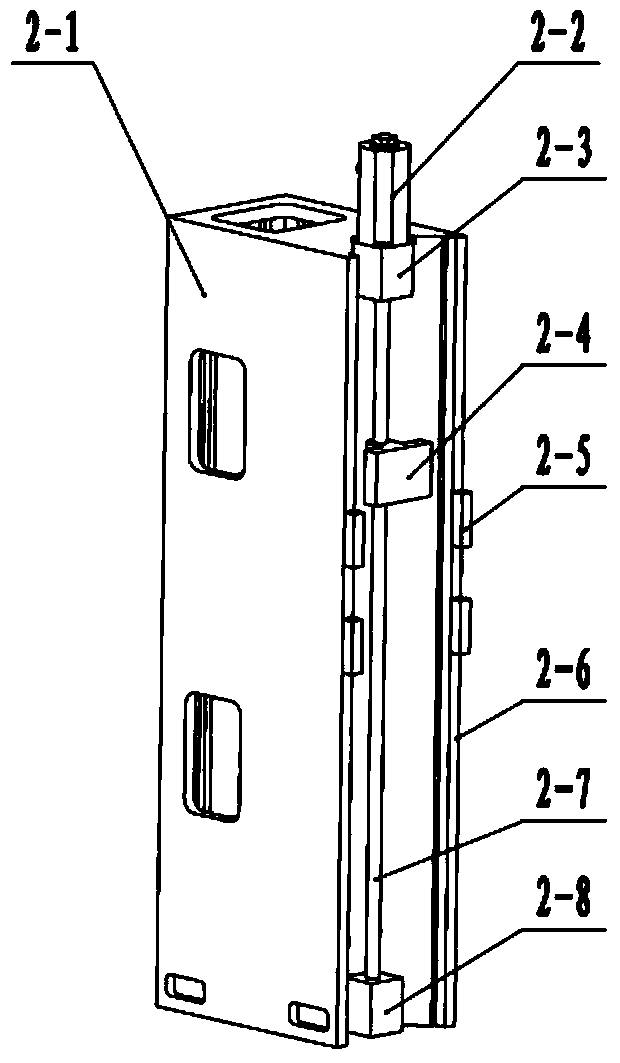

[0023] figure 1 It is a schematic structural diagram of a grinding system according to an embodiment of the present invention, such as figure 1 As shown, according to an embodiment of the present invention, the large-scale free-form surface robot grinding system includes a mobile gantry, an industrial robot 4, a pneumatic grinding head 5, a vision system, a robot control cabinet 8, a pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com