Multi-unit ultrasonic welding machine

An ultrasonic welding and multi-unit technology, which is applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems that weldments are difficult to achieve machine welding, etc., to ensure consistent quality, improve work efficiency, improve service life and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be explained below with reference to the drawings.

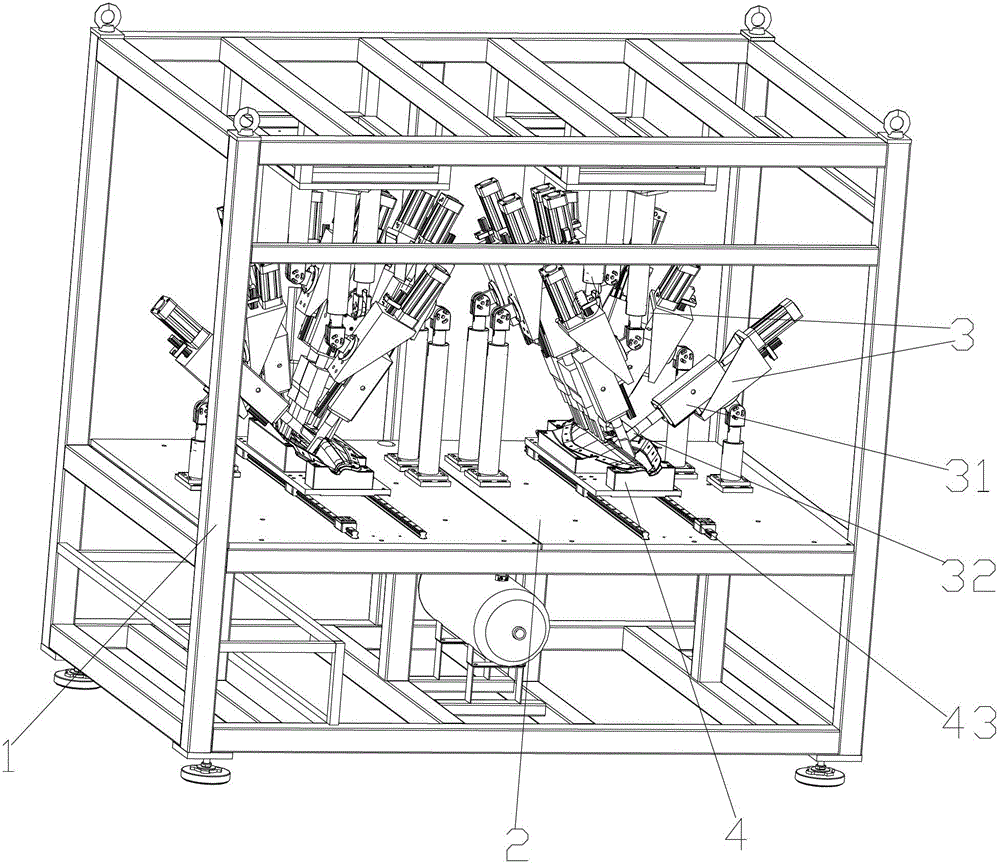

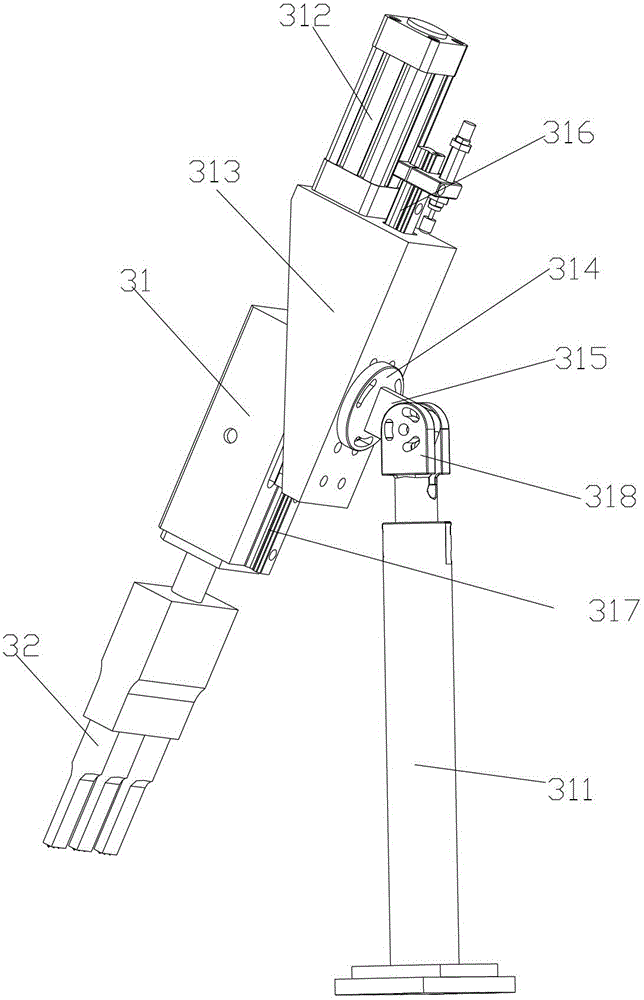

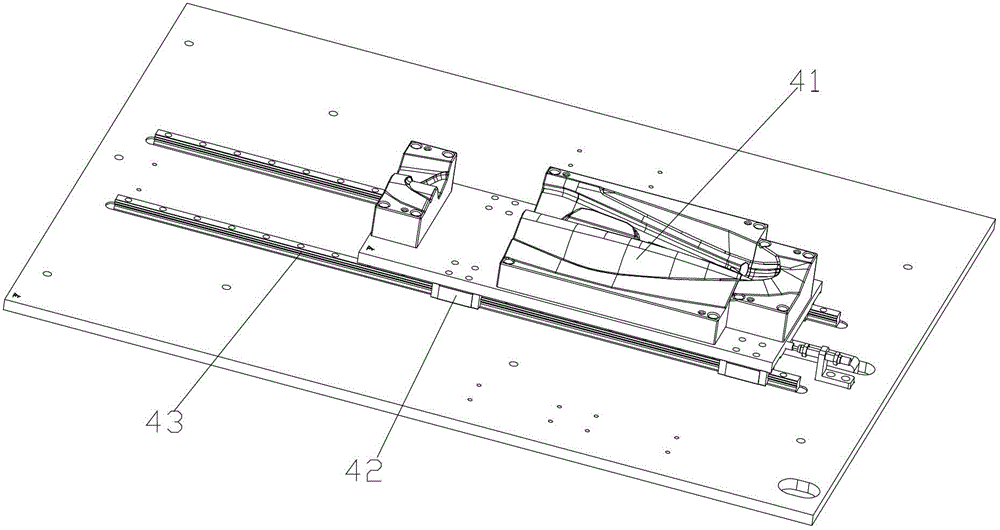

[0016] Attached Figure 1-4 It is a multi-unit ultrasonic welding machine according to the present invention, including a frame 1, on which a workbench panel 2 is provided, and at least a set of ultrasonic waves are respectively provided on the top of the frame 1 and the workbench panel 2 Welding device 3, in actual use, the number of sets of ultrasonic welding device 3 units can be determined according to the welding points of the weldment, and the ultrasonic welding device 3 units placed on the table panel 2 can be determined according to the actual use area of the workbench panel 2. The number of units of the ultrasonic welding device 3 hung upside down on the top of the frame 1; the workbench panel 2 is also provided with a fixed mold transmission device 4; the ultrasonic welding device 3 unit includes an ultrasonic welding control host 31, ultrasonic The welding head 32; the ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com