Combined throat liner spraying pipe of solid rocket engine and manufacturing method

A solid rocket and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as increased process difficulty and complexity, poor product quality consistency, large dispersion of material strength, etc., to achieve quality consistency Easy to guarantee, reduce the difficulty of production and processing, the effect of uniform carburizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

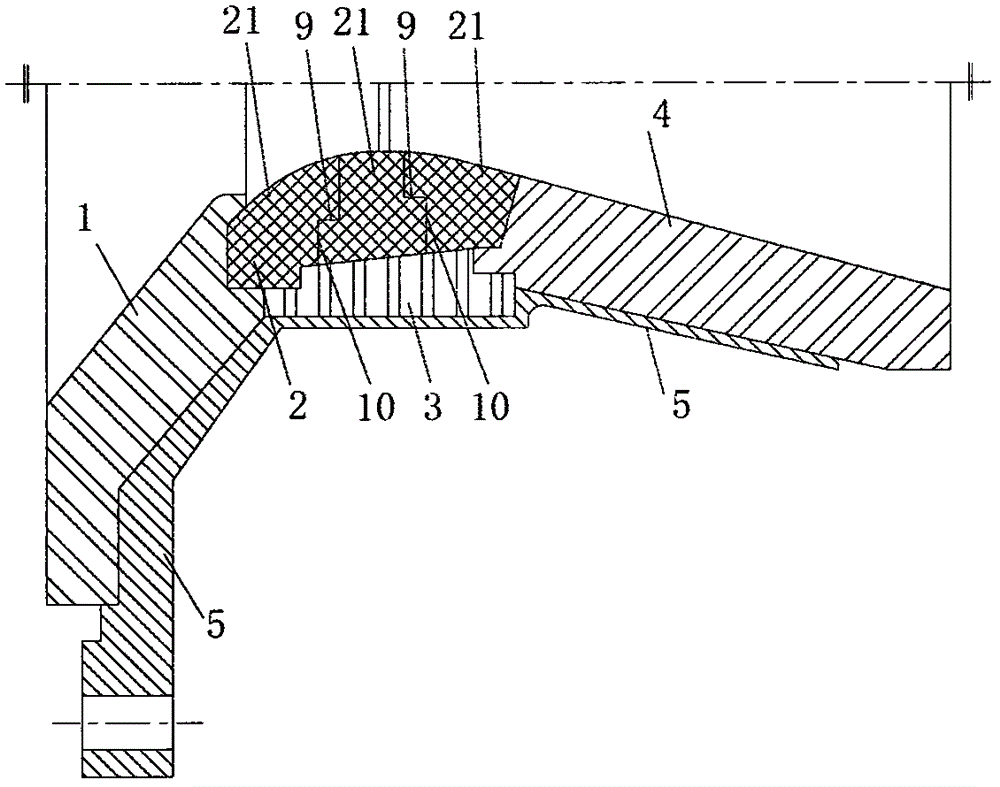

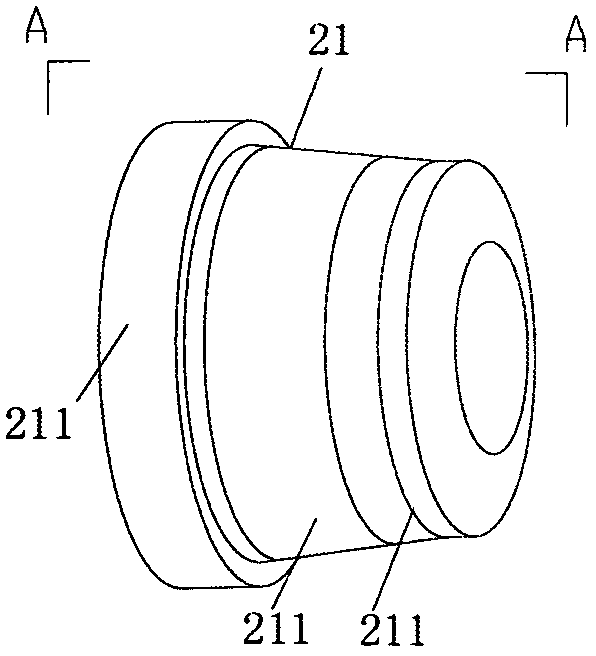

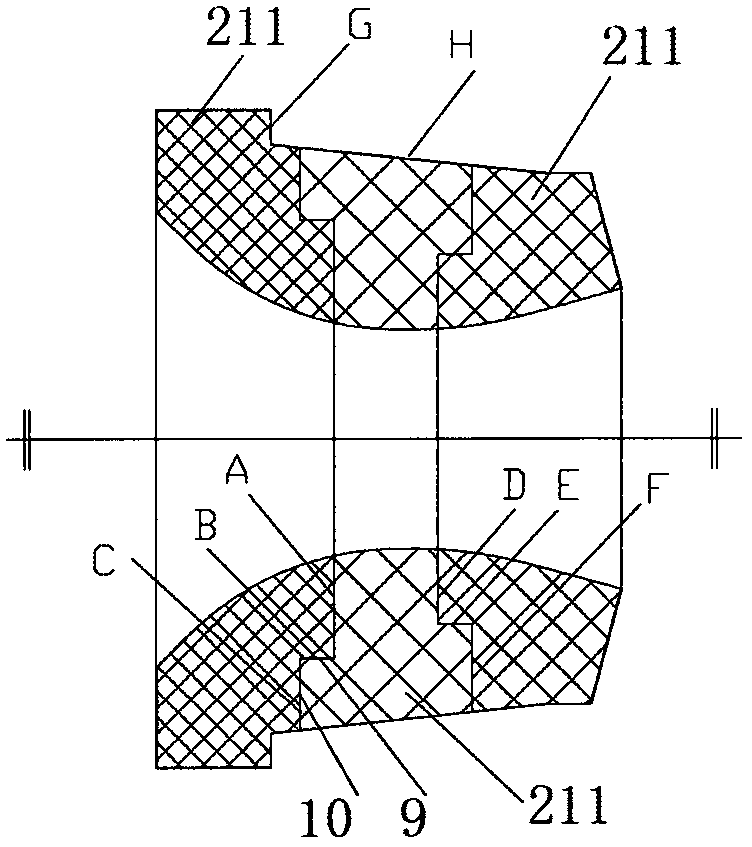

[0033] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a combined throat liner nozzle of a solid rocket motor includes axisymmetric rotary body structural components: a converging section heat insulation layer (1), a throat liner (2), a backing (3), a diffusion section heat insulation layer (4 ), the nozzle casing (5), the steps (9) formed by the axial cylindrical surface and the end surface are connected and sealed to assemble the nozzle between the parts, and the throat liner (2) is a combined throat liner, It is formed by connecting and sealing multiple throat inserts (21) in a stepped (9) style.

[0034] In this embodiment, the throat liner block (21) is an axial throat liner block (211) divided in the axial direction, and the specific number of throat liner blocks (21) can be adjusted according to the actual size and product equipment capacity. The example is 3 pieces; all adopt " L " type step turning bending gap 10 less than 3 times between ...

Embodiment 2

[0036] Example 2, such as Figure 5 , Figure 6 , Figure 7 As shown, a combined throat liner nozzle of a solid rocket motor includes axisymmetric rotary body structural components: a converging section heat insulation layer (1), a throat liner (2), a backing (3), a diffusion section heat insulation layer (4 ), the nozzle casing (5), the steps (9) formed by the axial cylindrical surface and the end surface are connected and sealed to assemble the nozzle between the parts, and the throat liner (2) is a combined throat liner, It is formed by connecting and sealing multiple throat inserts (21) in a stepped (9) style.

[0037] In this embodiment, the throat lining block (21) is a radial throat lining block (212) divided in the radial direction, and the specific number of throat lining blocks (21) can be adjusted according to the actual size and product equipment capacity. For example, there are 3 pieces; the radial throat liner blocks (212) are connected and sealed by "L"-shape...

Embodiment 3

[0039] Example 3, such as Figure 5 , Figure 6 , Figure 7 As shown, a combined throat liner nozzle of a solid rocket motor includes axisymmetric rotary body structural components: a converging section heat insulation layer (1), a throat liner (2), a backing (3), a diffusion section heat insulation layer (4 ), the nozzle casing (5), the steps (9) formed by the axial cylindrical surface and the end surface are connected and sealed to assemble the nozzle between the parts, and the throat liner (2) is a combined throat liner, It is formed by connecting and sealing multiple throat inserts (21) in a stepped (9) style.

[0040] In this embodiment, the throat lining block (21) is a two-way throat lining block (213) that is divided axially or radially. The specific number of throat lining blocks (21) can be determined according to the actual size and product equipment capacity The situation is adjusted, and the present embodiment has 9 pieces, which are divided into 3 sections in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com