Worm and screw processing device

A processing equipment and screw technology, applied in the field of screw processing equipment and worms, can solve the problems of affecting the consistency of the processing quality of the worm screw, reducing the processing accuracy of the worm screw, and high equipment cost, and achieving a simple structure and consistent threads. The effect of good sex and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

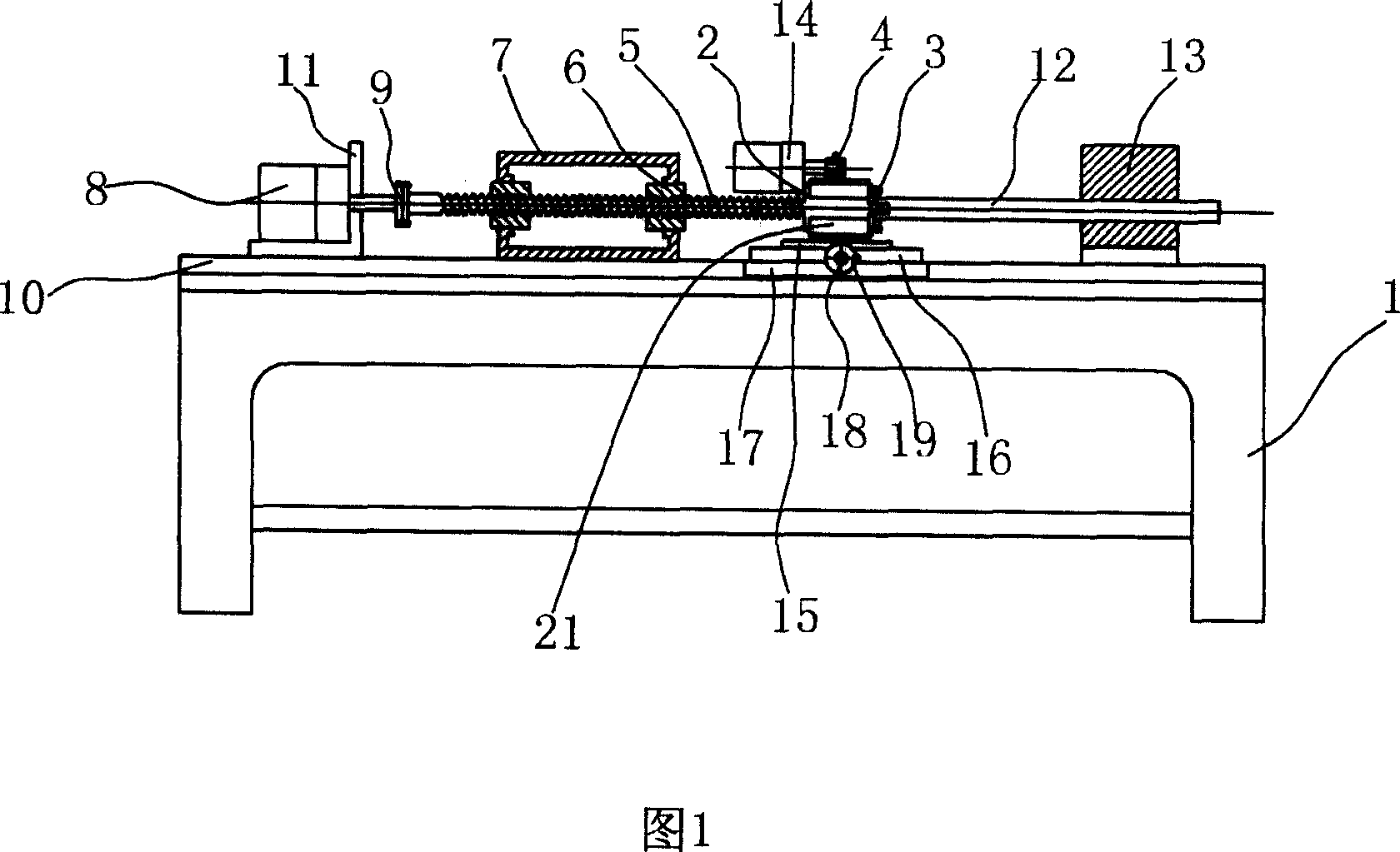

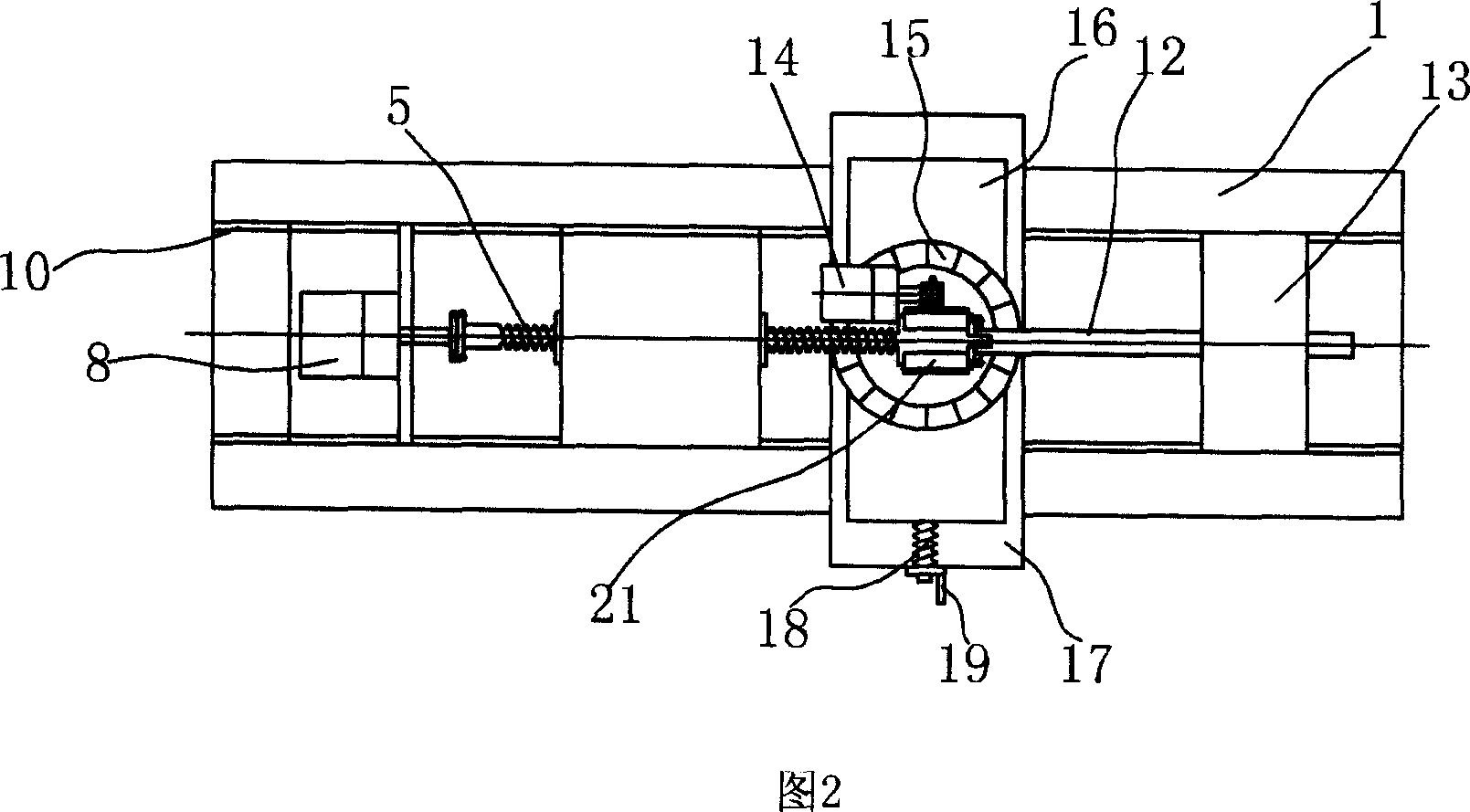

[0020] Embodiment 1: As shown in Figure 1 and Figure 2, a worm screw machining milling machine includes a bed 1, a workpiece fixture composed of a driving chuck 2 and a driven chuck 3 oppositely arranged and corresponding to the workpiece The tool 4 on the side of the workpiece is clamped by the fixture, and the workpiece feed mechanism for driving the workpiece fixture to rotate and axially translate includes a movable threaded body 5 and a static threaded body 6 fixed on the bed 1 that are threaded to each other. The threaded body 5 is represented here as a screw rod, and the static threaded body 6 is represented here as one or two nuts coaxially fixed by the nut base 7 which are matched with the screw thread. The tool 4 is represented here as a circular milling cutter. , One end of the movable threaded body 5 and the output end of the feed power source 8 are drivingly connected through a coupling 9, and the other end of the movable threaded body 5 is fixedly connected with the ...

Embodiment 2

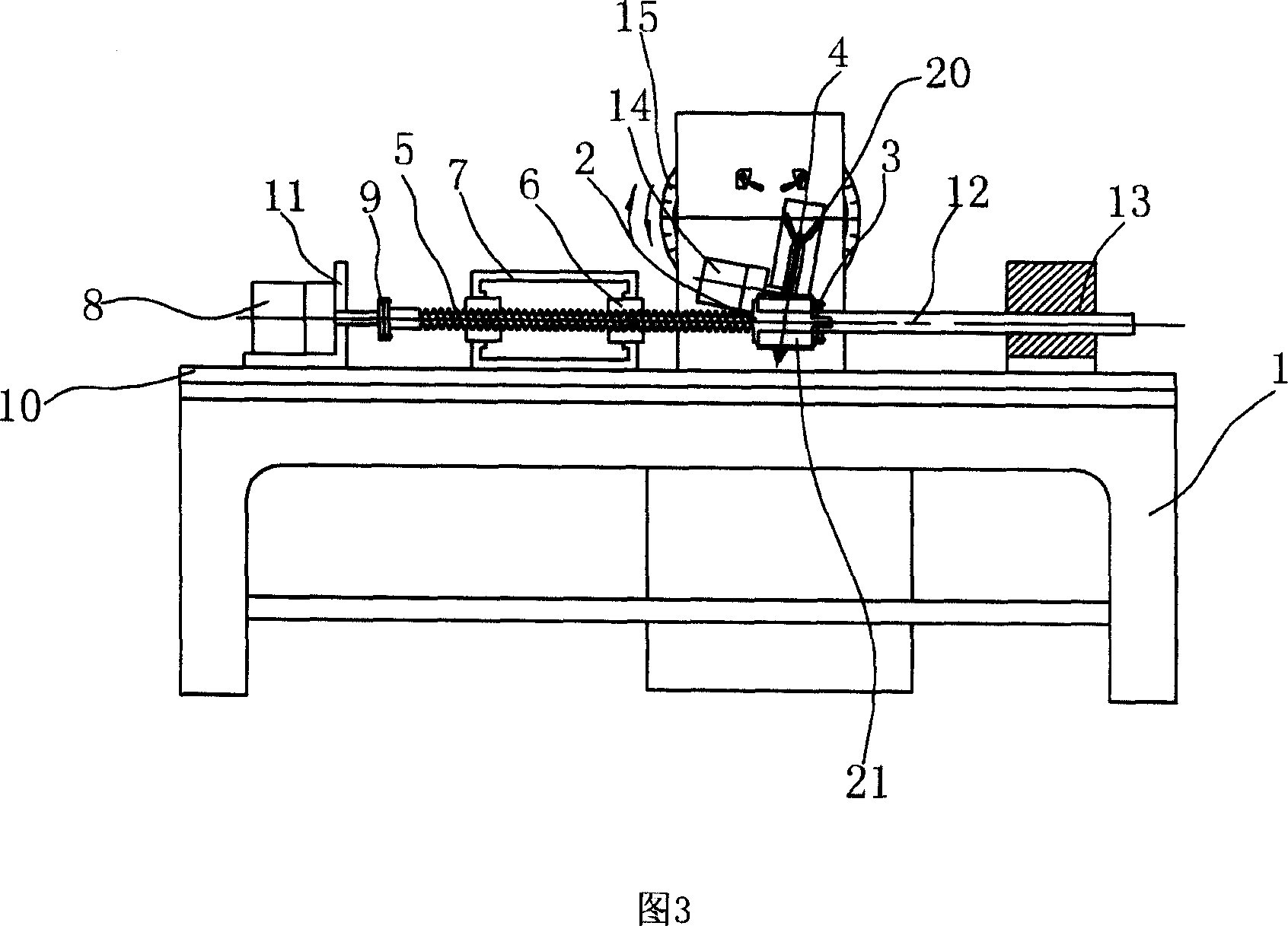

[0023] Embodiment 2: As shown in Figures 3 and 4, a worm screw machining grinder includes a bed 1, a workpiece fixture composed of a driving chuck 2 and a driven chuck 3 oppositely arranged and corresponding to the workpiece The tool 4 on the side of the workpiece is clamped by the fixture, and the workpiece feed mechanism for driving the workpiece fixture to rotate and axially translate includes a movable threaded body 5 and a static threaded body 6 fixed on the bed 1 that are threaded to each other. The threaded body 5 is represented here as a screw rod, and the static threaded body 6 is represented here as one or two nuts coaxially fixed by the nut base 7 which are fitted with the screw rod. The tool 4 is represented here as a circular grinding wheel. Diamond pens 20 for repairing the grinding wheel are respectively provided on both sides of the circular grinding wheel. One end of the movable threaded body 5 is connected to the output end of the feed power source 8 through a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com