Chip packaged fixed focus focusing-free imaging module processing method

A technology for chip packaging and camera modules, which is applied in installation, radiation control devices, and printed circuits connected with non-printed electrical components. Achieve the effect of saving product testing equipment and man-hours, improving production efficiency, and improving quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

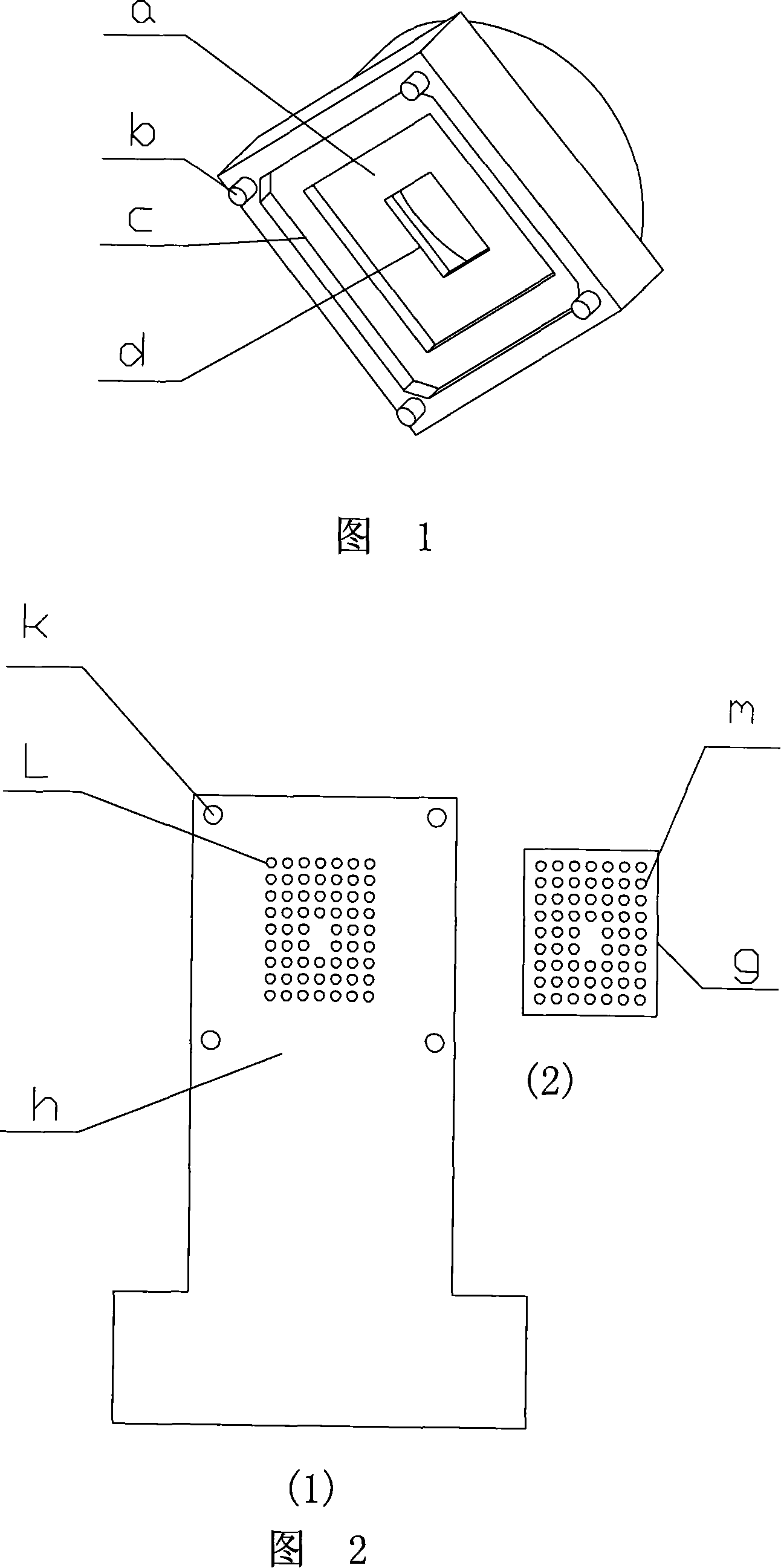

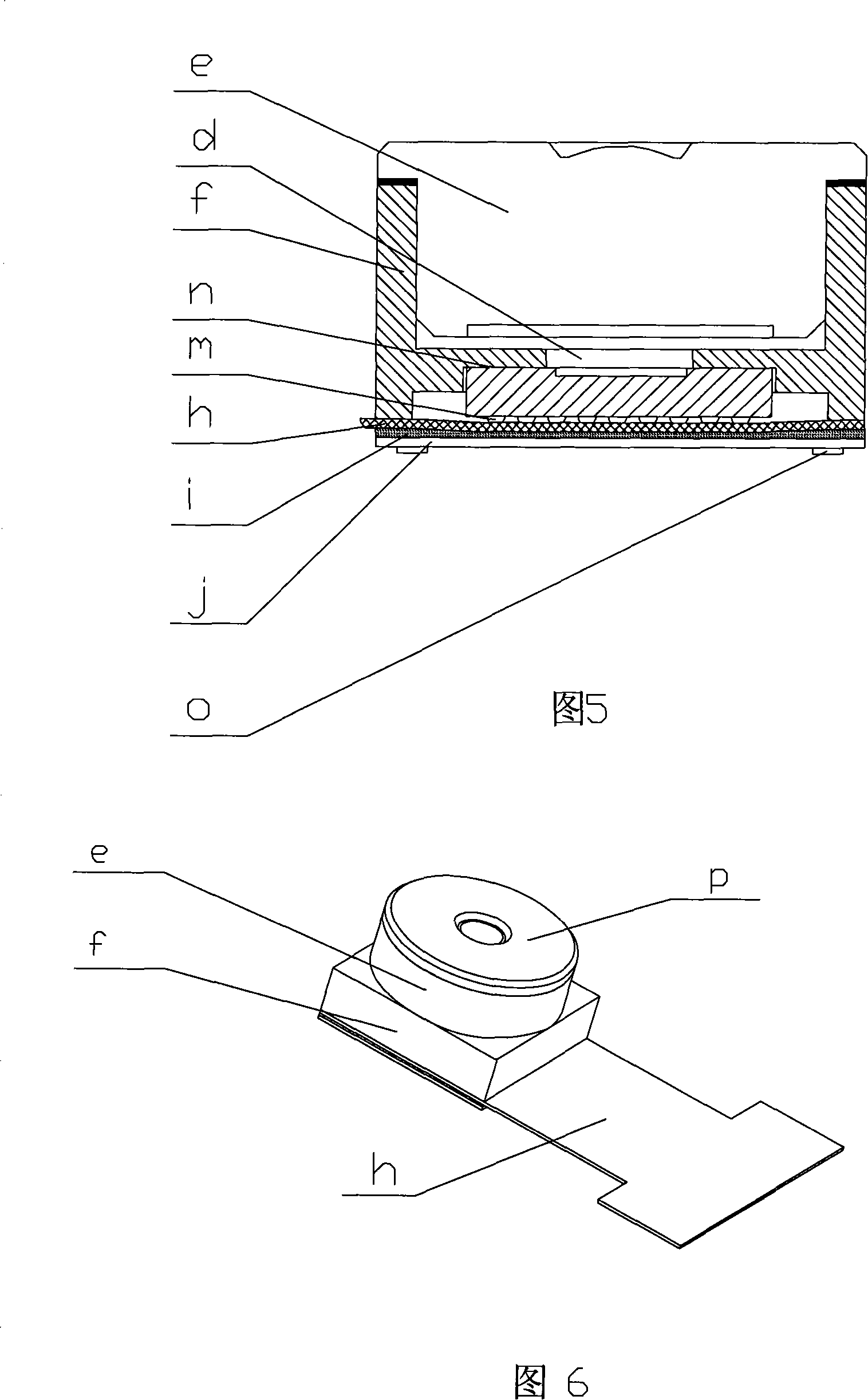

[0029] 1. Prepare lens e: Lens e is wrapped with several lenses inside a plastic shell. Ordinary lens e has threads on the outside, and lens mount f also has threads on the inside. Lens e is screwed in the lens mount f. No need to focus now. The connection between the lens e and the lens holder f is a universal tight-fitting and pressing method. They are pressed together by interference fit. The differences between the lenses are corrected by molds or compensation methods to ensure that the resolution of each lens e is within ± Within 10% error. The lens e has no thread on the outside.

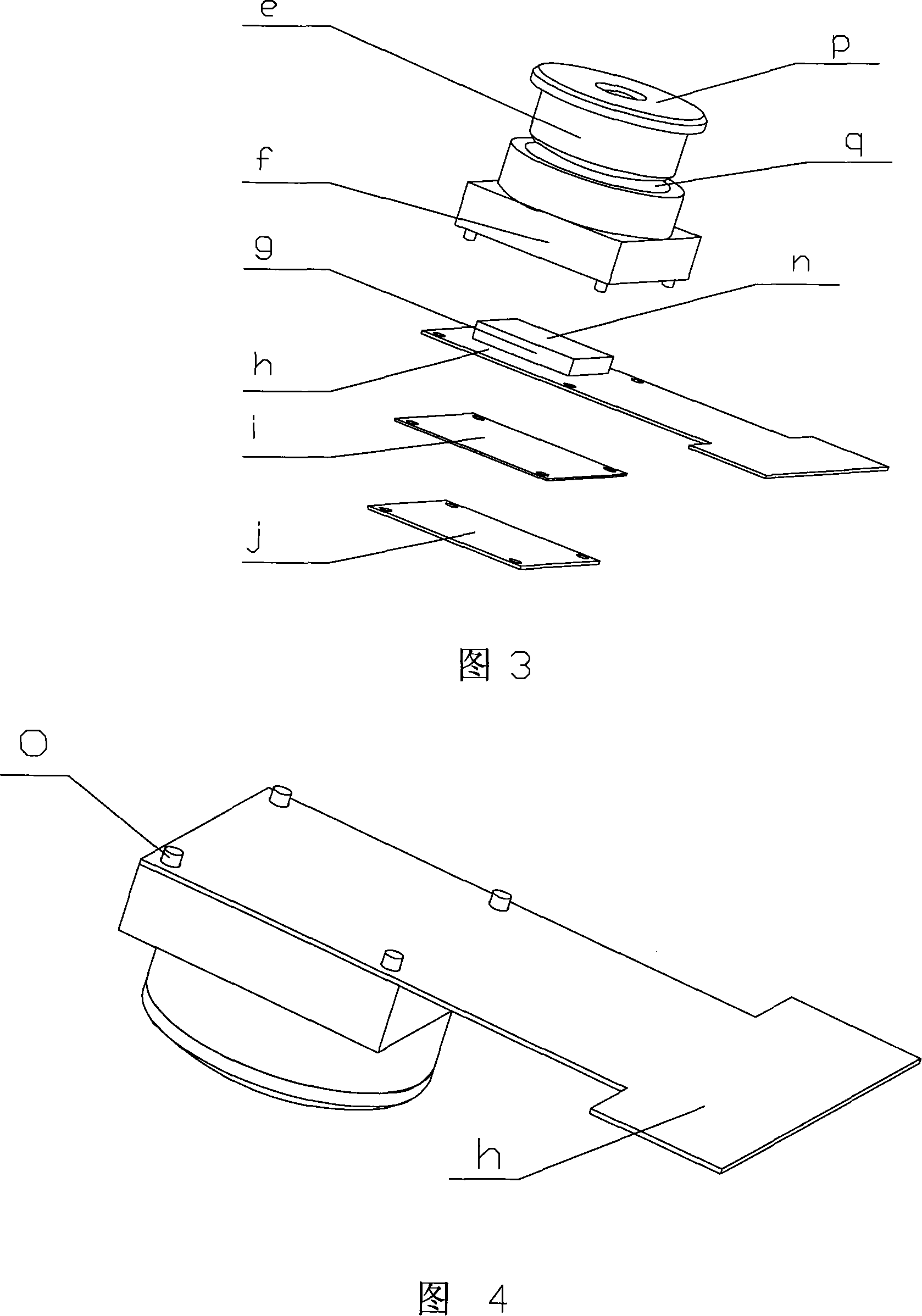

[0030] 2. Prepare the mirror holder f: the bottom surface of the mirror holder f has a positioning surface groove a, and the plane size of the positioning surface groove a is 0.2-0.5mm larger than the image sensor g, so that the image sensor g can be embedded inside, and the image sensor The top of g is just in close contact with the positioning surface groove a of the mirror base f, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com