Marine low-speed machine air valve welding robot work station control system

A welding robot and robot control cabinet technology, applied in the field of welding processing, can solve problems such as difficult equipment perfect coordination, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

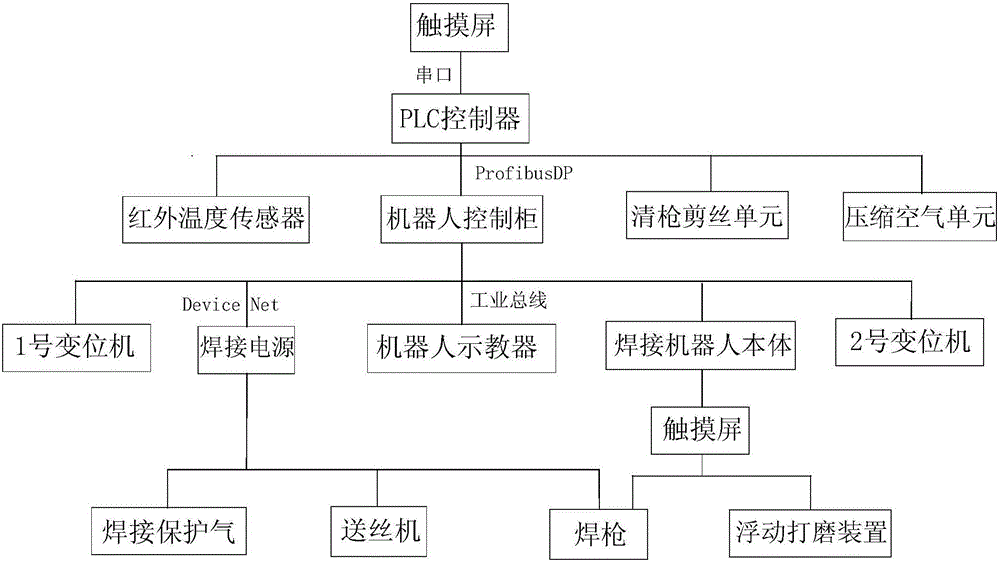

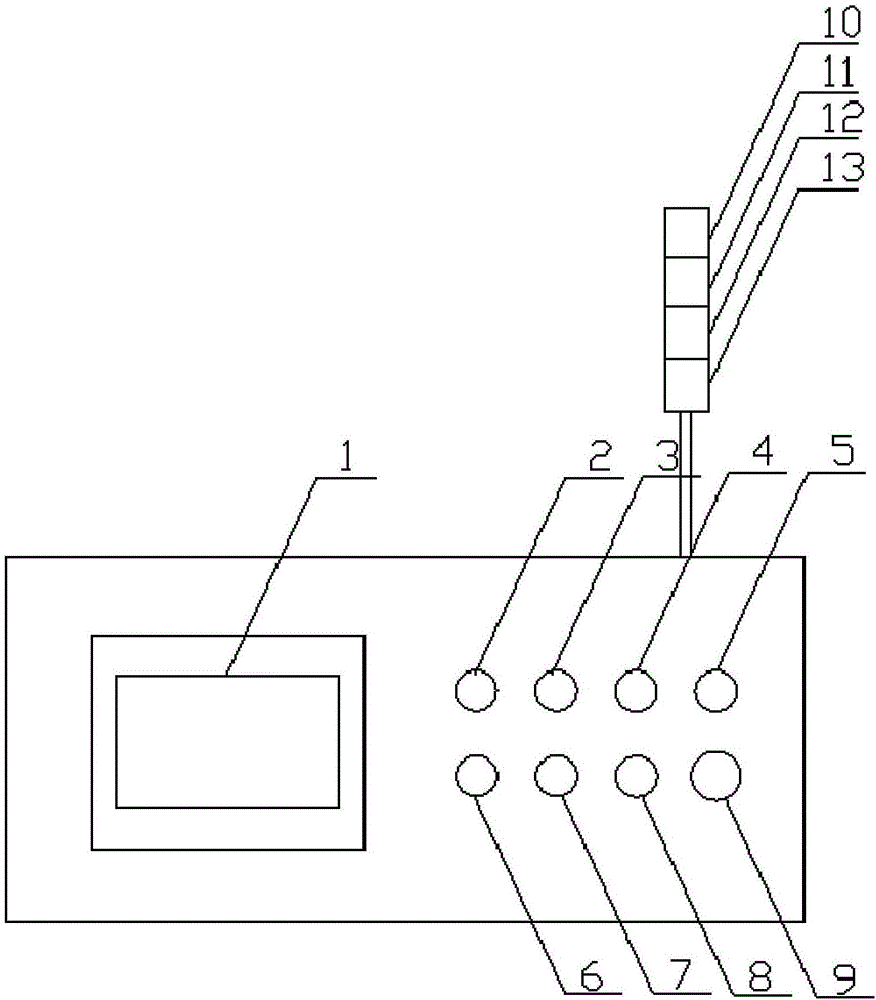

[0024] This embodiment provides a control system for a marine low-speed machine gas valve welding robot workstation, such as figure 1 As shown, including the central control system, robot control system, welding control system and sensor detection system. Among them, the central control system includes the main controller of the robot, which communicates with the robot control system through the Profibus DP bus to realize mutual information interaction, and obtains sensing information through the I / O module to control the action of the welding robot. The robot control system includes a robot control cabinet, a robot teaching device, controls the movement of the robot body and positioner in the workstation, and communicates with the welding power supply through the Devicenet bus to control the work of the welding system. The sensor detection system includes an infrared temperature sensor installed on the welding torch, a pressure switch and a cylinder magnetic switch. Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com