Ethernet-based redundancy control system and control method

A redundant control and control system technology, applied in general control systems, control/regulation systems, program control, etc., to achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

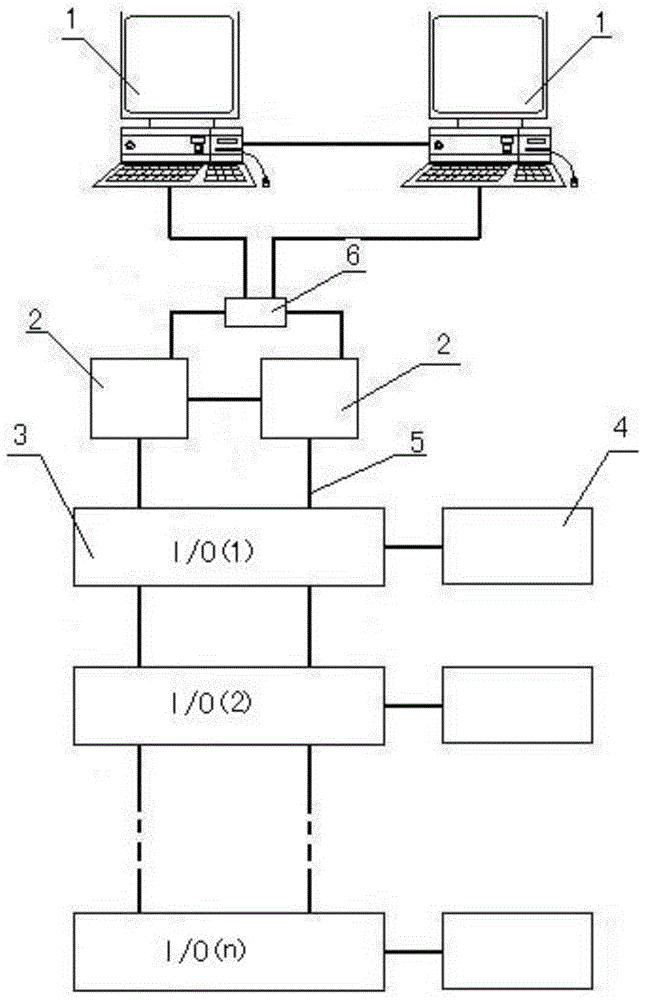

[0029] Such as figure 1 As shown, an Ethernet-based redundant control system includes a host system, a control system and an execution system;

[0030] The host system includes two industrial computers 1, each of which is equipped with configuration software, and the two industrial computers 1 form a local area network through a standard network card, and realize timely data update and exchange between the two industrial computers 1 through the local area network; If the industrial computer 1 fails, it will not affect the other one to continue to work;

[0031] The control system includes two sets of PLC systems 2 both equipped with software. The PLC system 2 includes power supply modules, redundant CPUs and Ethernet communication modules for redundant CPU communication. The redundant CPUs in the two sets of PLC systems 2 use Optical fiber connection to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com