Automatic control system for moderate-thickness plate roller quenching machine

An automatic control system, thick plate roll technology, applied in quenching devices, heat treatment process control, manufacturing tools, etc., can solve the problems of low automation level and poor control accuracy, reduce manual intervention, improve production efficiency, save money cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

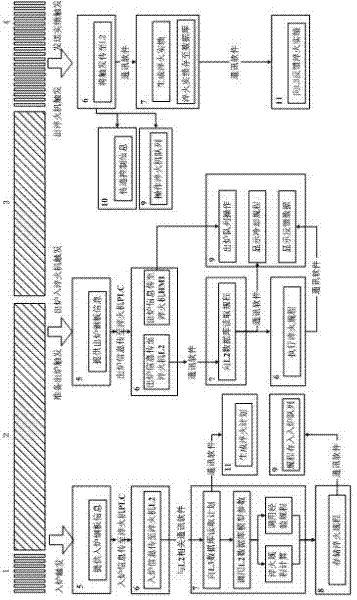

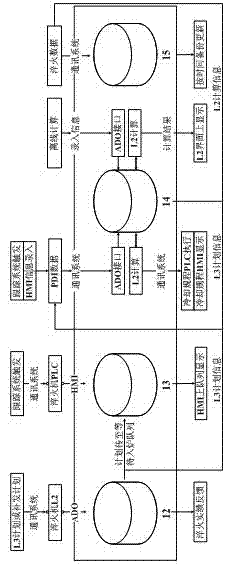

[0031] The technical scheme of the automatic control system of the plate roller quenching machine in the quenching (solution) heat treatment mode and the continuous production mode.

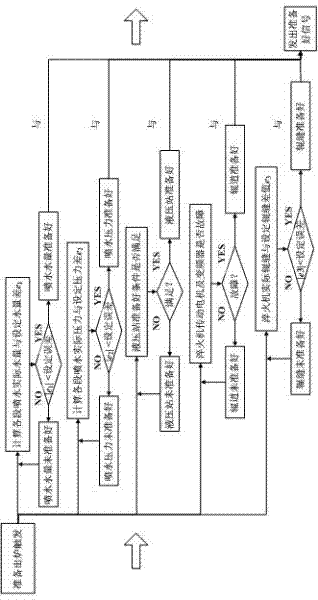

[0032] Such as Figure 1~3 As shown, when the PLC system 5 of the heat treatment furnace receives the furnace entering signal, the signal is transmitted to the quenching machine PLC6 through the PLC communication between equipments, and the number of the steel plate entering the furnace is also transmitted at the same time. Quenching machine PLC6 passes the steel plate number into the furnace to quenching machine L27, and the latter inquires the plan information of the steel plate into the furnace from L311 by virtue of the plate number, and stores the information in the quenching machine plan and performance database 12. The quenching machine L27 queries the quenching machine model database 14 for physical property parameters, model parameters and default values based on the steel type, alloy ...

Embodiment 2

[0034] The technical scheme of the automatic control system of the plate roller quenching machine in the normalizing or annealing heat treatment mode and the empty production mode.

[0035] The trigger mode, communication mode, tracking system operation mode, and database reading mode of this example are the same as those of the previous example, and will not be repeated here. The difference is that if the heat treatment mode in the steel plate information obtained by the quenching machine L27 is normalizing or annealing, the calculation of the quenching schedule is not performed, and the air cooling schedule is directly formulated, and the schedule is saved in the queue database 13 of the quenching machine. The air cooling procedure is: the frame of the quenching machine is raised to 400mm, the speed of the quenching machine is 0.6m / s, the upper nozzles of all quenching sections are closed, and the lower nozzles are kept at 50m for each quenching section 3 / h Constant running ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com