Ammonium salt-containing tobacco leaf reproduced by means of rolling

A technology of reconstituted tobacco leaves and rolling method, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of flat aroma, uncomfortable aftertaste, bitter and spicy tongue, etc., to achieve clean mouth, improve sensory quality, and improve aftertaste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

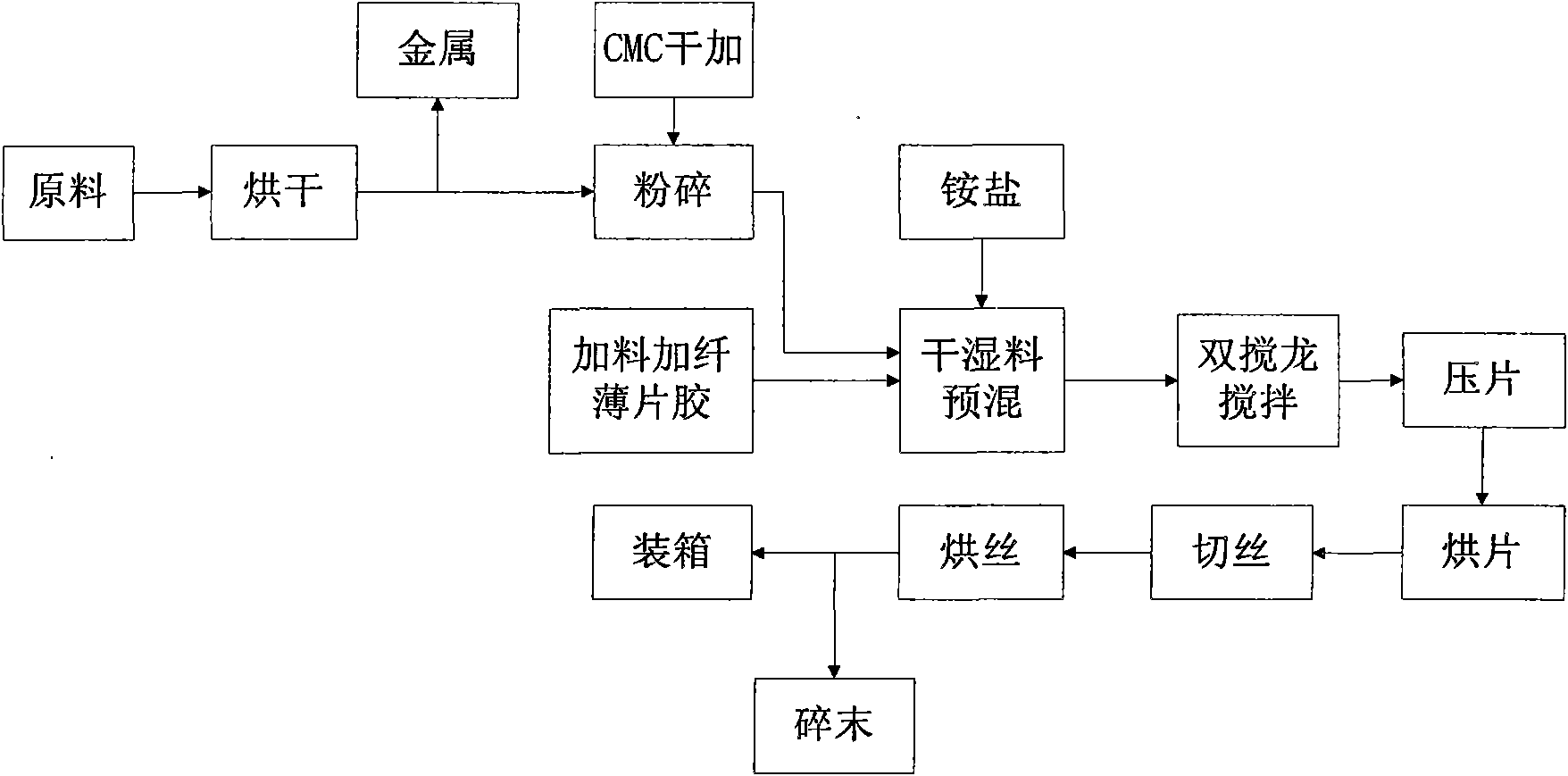

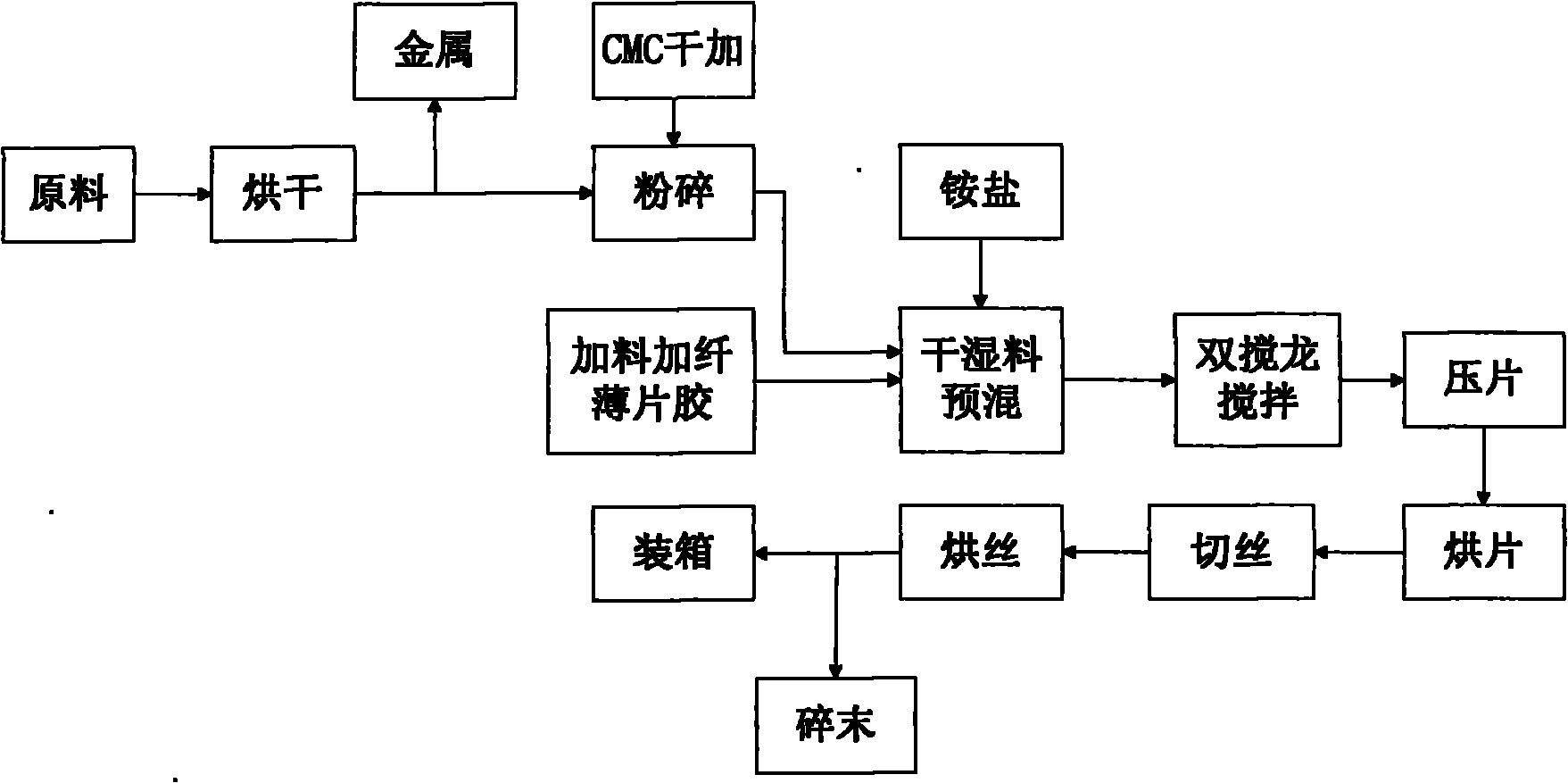

Method used

Image

Examples

Embodiment 1

[0024] A preparation of ammonium salt-containing reconstituted tobacco leaves by rolling method:

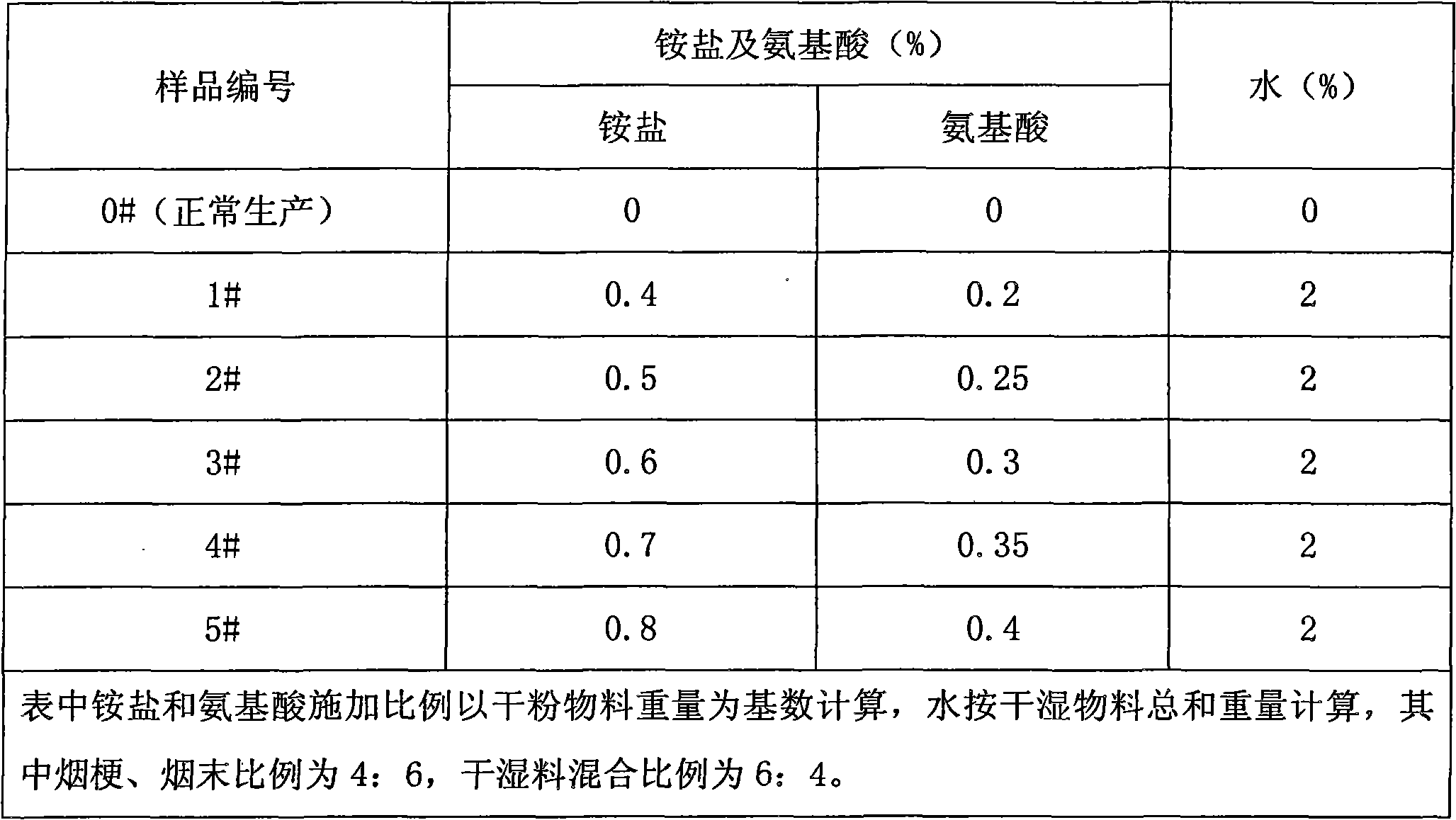

[0025] 1) Mix ammonium salt and amino acid (see Table 1 for details of materials), dissolve and dilute with 2% water (calculated based on the total weight of dry and wet materials), and stir evenly to prepare an ammonium salt solution;

[0026] 2) Feed the mixing tank. The weight ratio of dry and wet materials mixed is 6:4. When the materials reach the required weight, stop feeding the dry and wet materials;

[0027] 3) Add the prepared ammonium salt solution evenly into the dry and wet material mixing tank, and fully stir. After the dry and wet materials and the ammonium salt solution are mixed evenly, perform tablet production. After drying, shredding, and drying processes, Obtain the finished reconstituted tobacco leaves.

[0028] Dry material: pretreated tobacco stems and tobacco powder (produced by Qingzhou Cigarette Factory, the weight ratio is 4:6) and CMC (Shandong Yutai...

Embodiment 2

[0039] The preparation of the reconstituted tobacco leaf of rolling method that contains ammonium salt: method is the same as embodiment 1, difference is used

[0040] Ammonium salt: 15 parts by weight of ammonium dihydrogen phosphate, 19 parts by weight of diammonium citrate, 15 parts by weight of ammonium carbonate, 18 parts by weight of ammonium acetate, 15 parts by weight of ammonium phosphate, 15 parts by weight of ammonium tartrate, 19 parts by weight of ammonium citrate mixture.

[0041] The amino acid is a mixture of 44 parts by weight of glutamic acid, 31 parts by weight of alanine, and 41 parts by weight of asparagine.

Embodiment 3

[0043] The sensory comparison and smoking evaluation was carried out between the samples of the roll-pressed reconstituted tobacco leaves containing ammonium salts and the normal production samples. Sensory evaluation method:

[0044] After the sample was rolled, it was balanced for 48 hours at a temperature of 22° C. and a relative humidity of 60%, and then sensory evaluation was carried out. The sensory evaluation adopted a paired comparison test method. The sample cigarettes obtained in the present invention and the cigarettes normally produced in the prior art comparing. After sensory evaluation, the sample of reconstituted tobacco leaves with ammonium salt added by roller pressing method has a stronger smell, natural smoke aroma, no miscellaneous gas and prickly feeling, the smoke has a sweet and moist feeling, the mouth is clean, and it enters the throat smoothly. (See Table 3 for the evaluation results)

[0045] Table 3 Sensory quality evaluation report

[0046]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com