Isothermal methanation process method for coal to substitute natural gas

A technology of coal-to-natural gas and process method, which is applied in the application field of coal-to-natural gas to achieve the effect of reducing operating costs, lowering the maximum operating temperature, and saving equipment construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

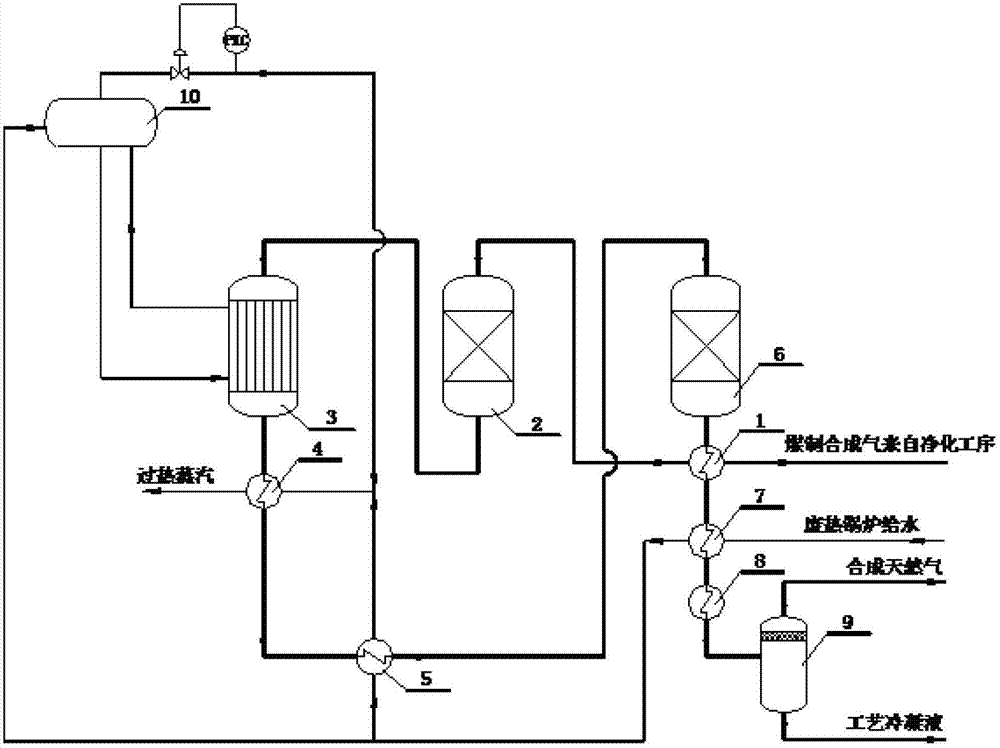

[0040] as attached figure 1 As shown, the method of the embodiment of the present invention is mainly completed by the following system, which mainly includes: (a) a fine desulfurization tank for controlling the total sulfur content in the reaction raw material gas; (b) a preheating tank for the reaction raw material gas Feed gas preheater; (c) an isothermal methanation reactor as the main reactor; (d) a steam superheater for high pressure steam superheating and medium pressure steam for controlling the inlet gas temperature of the second methanation reactor Waste pot; (e) an adiabatic methanation reactor for controlling CO content in product natural gas.

[0041] The isothermal methanation process of coal-to-natural gas is carried out in the following steps:

[0042] The purified synthetic gas from the upstream is sent to the feed gas preheater to exchange heat with the hot gas from the outlet of the adiabatic methanation reactor, and then preheated to 280°C. The preheated g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com