Boiler

A boiler and squatting technology, applied in the field of squatting boilers, can solve the problems that the heat exchange area cannot be too large, the volume of the horizontal boiler is large, and the degree of automation is low, and achieves the effects of small size, low labor intensity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

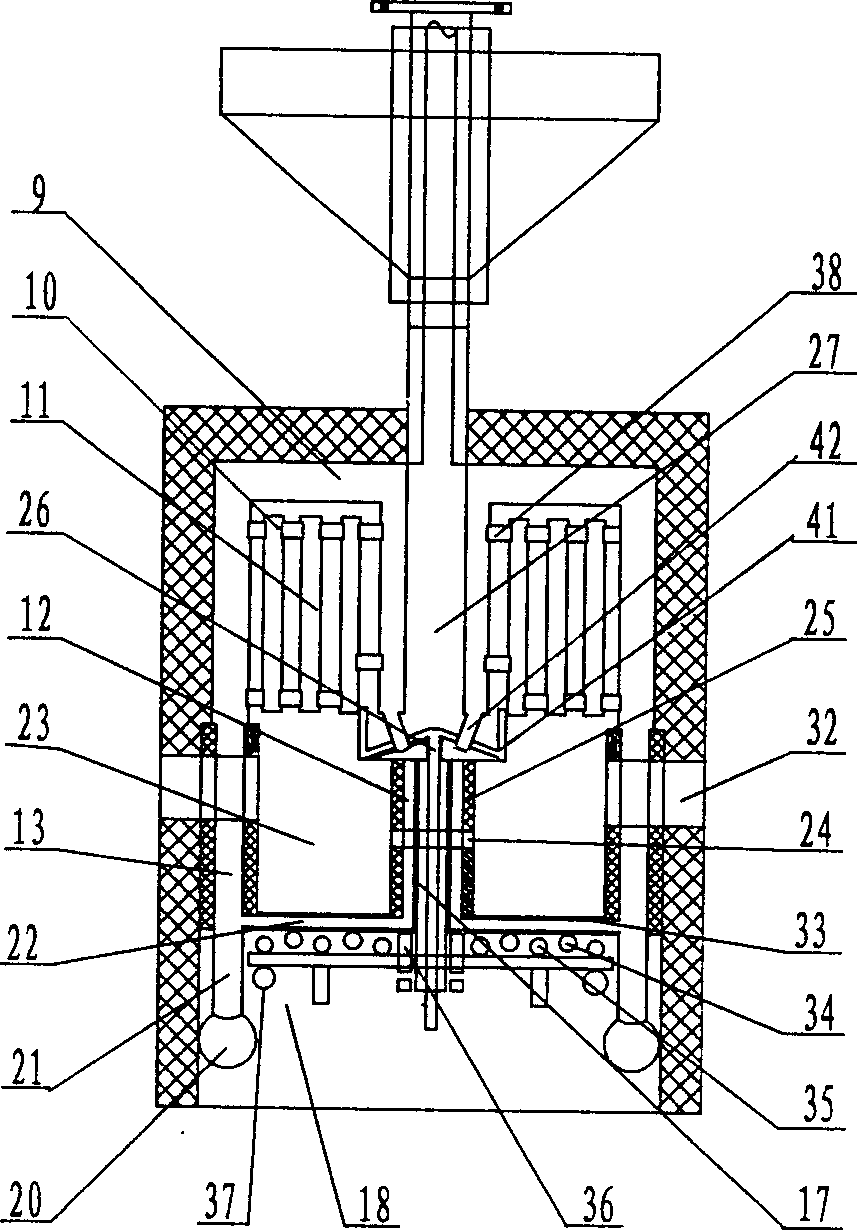

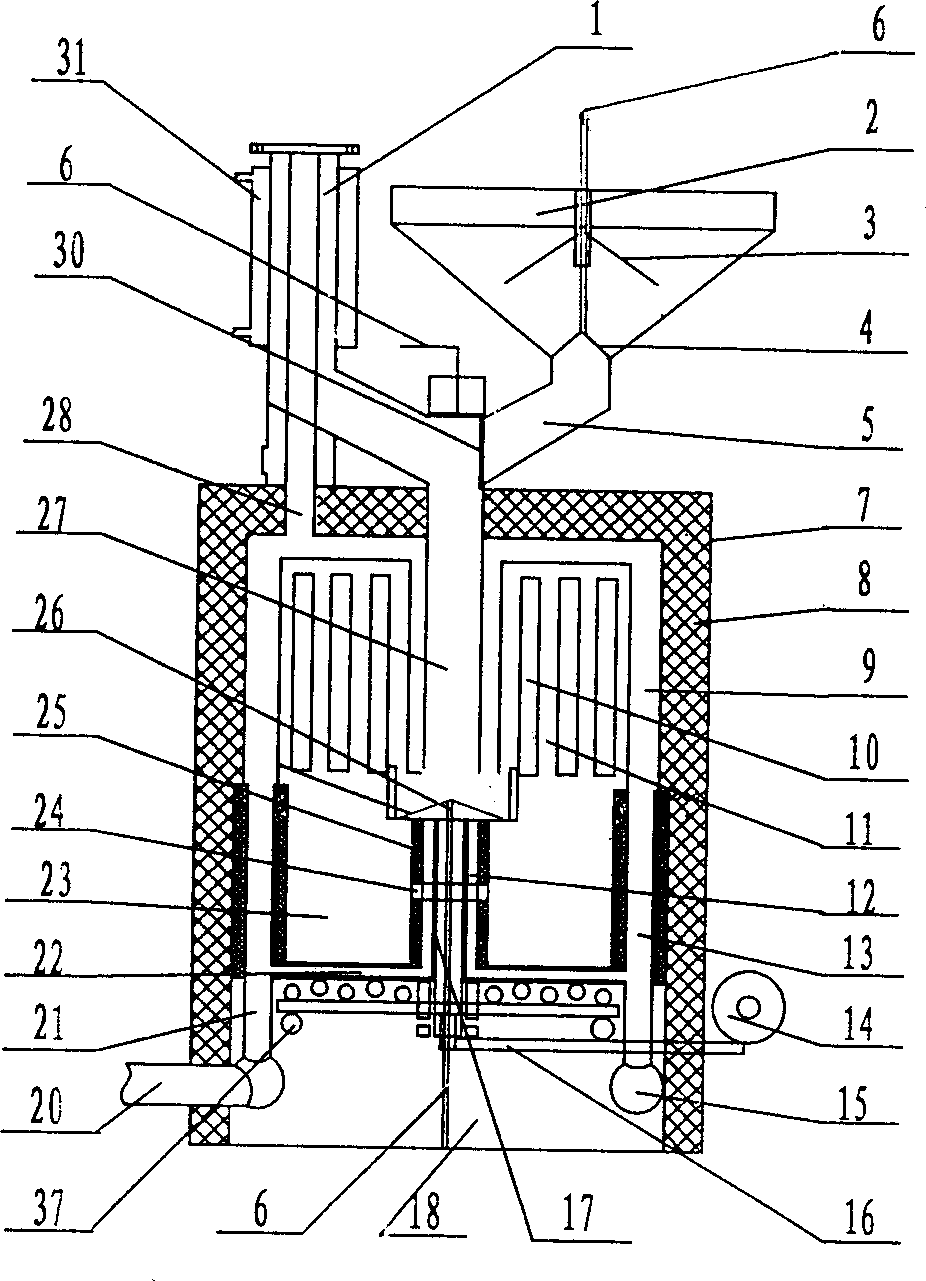

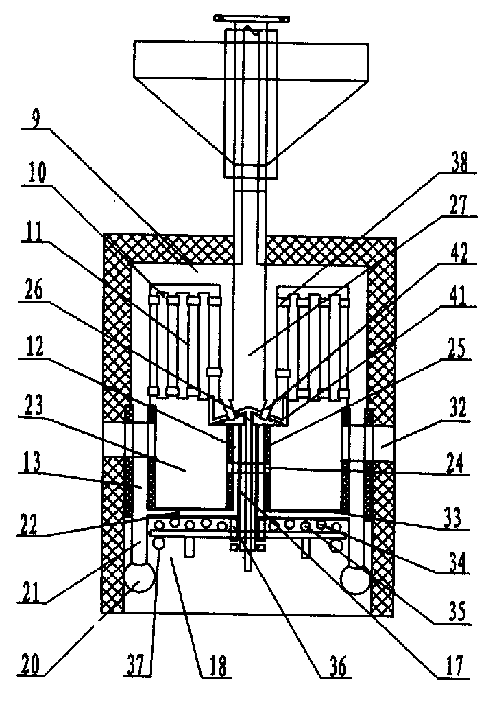

[0019] Embodiment one: if figure 1 with figure 2 As shown, a squatting boiler includes a chimney, a furnace body, a furnace, a coal feeding device, an ash removal device, and a power device for controlling coal feeding and ash removal. It is characterized in that the coal feeding device is located at the top of the furnace body, and the furnace The outer layer is the furnace shell 7, inside the shell is the insulation material 8, the middle is the furnace, the upper part of the furnace is the upper heat exchange chamber 11, the lower part is the combustion chamber 23, and the center of the upper heat exchange chamber 11 is hollow for smoke exhaust and coal supply. The common channel 27 is composed of an inverted U-shaped water jacket 9, a heat exchange tube water jacket 10 and a water pipe 38 connecting the two; the combustion chamber 23 is an outer water pipe 13 connected to the outside of the U-shaped water jacket 9, located in The inner water pipe 12 under the common chan...

Embodiment 2

[0021] Embodiment 2: The rest is the same as Embodiment 1. There is a turbulence barrier 26 at the top of the inner water pipe 12, which is used to increase the resistance of the flue gas, prolong the residence time of the hot flue gas, and increase the heat transfer effect. The middle part has a combustion-supporting Vents 24 are formed.

Embodiment 3

[0022] Embodiment 3: The rest is the same as Embodiment 1. The ash removal device is composed of fixed furnace teeth 34, movable furnace teeth 35, ash removal rocker lever 16, central axis tube 17, bracket 18, and ash removal transmission rod 16. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com