Outer burner cap with flame avoiding and flame propagation properties

A technology for an outer fire cover and a burner, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of reducing the CO content of the combustion exhaust, insufficient flame combustion, and long flame propagation, so as to reduce the CO content. , The ignition performance is reliable, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

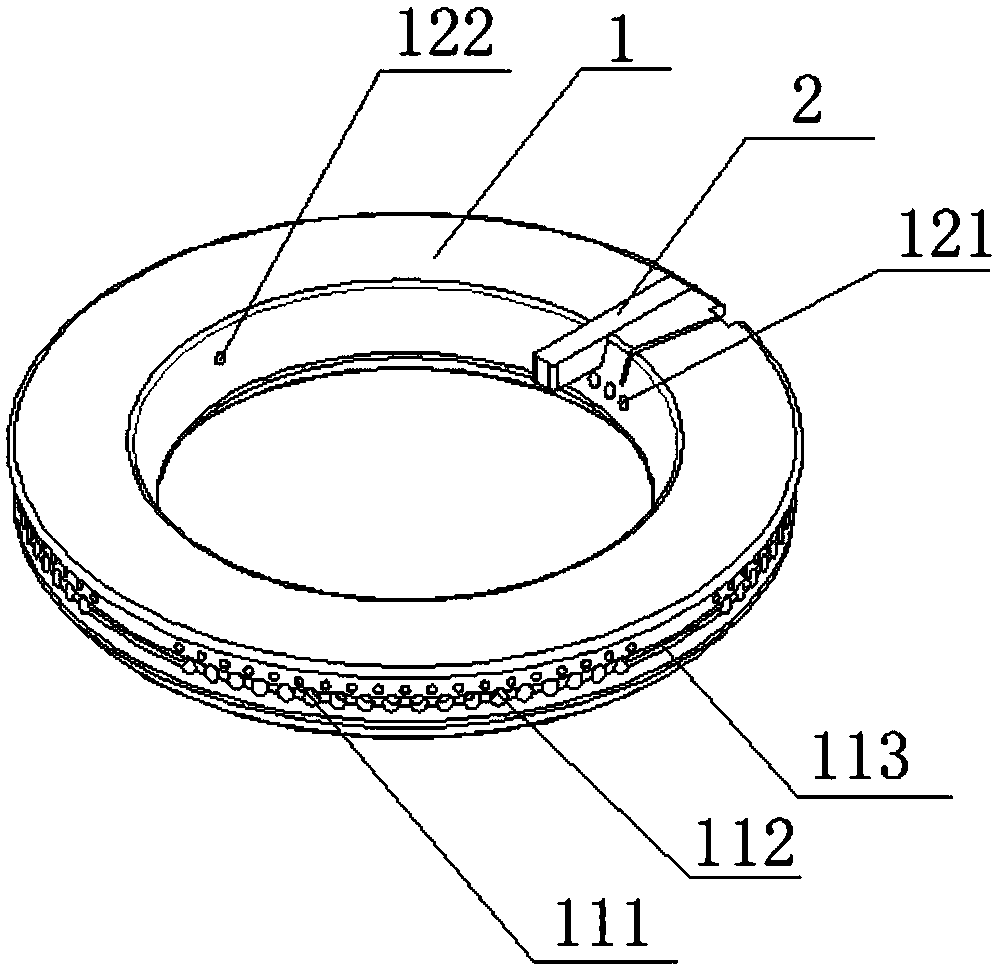

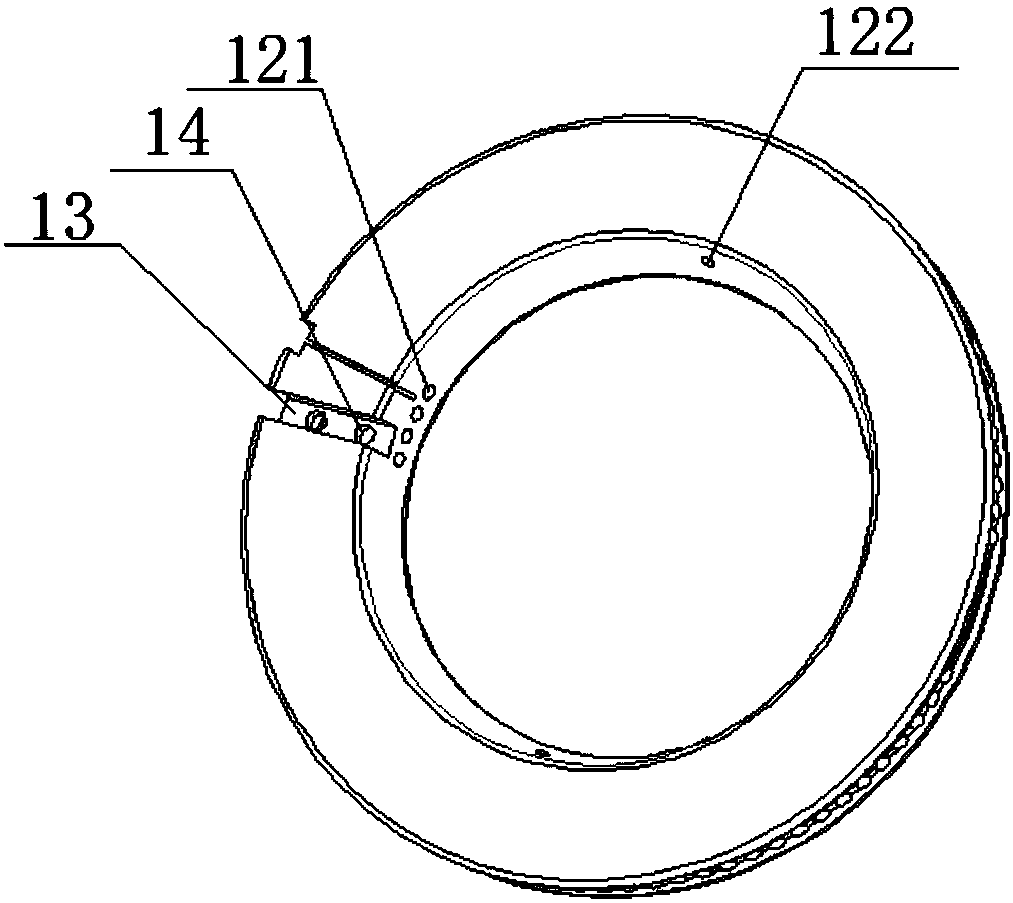

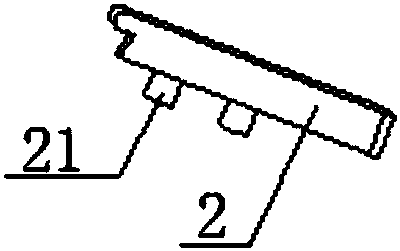

[0021] see Figure 1-4 As shown, a burner outer fire cover with fire avoidance and fire transfer performance provided by this embodiment includes an outer fire cover body 1 and a fire plate 2, and the outer fire cover body 1 includes an outer fire cover outer ring 11 and The inner ring 12 of the outer fire cover, the outer ring 11 of the outer fire cover is provided with upper and lower rows of fire through holes, the diameter of the upper row of fire through holes 111 is smaller than the diameter of the lower row of fire through holes 112, so The lower row of fire holes 112 are the main combustion fire holes, the upper fire hole 111 is the main fire steady flame hole, and the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com