Low cost hydrogen storage alloy, preparation method and application thereof

A hydrogen storage alloy, low-cost technology, applied in the field of hydrogen storage alloy and its preparation, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

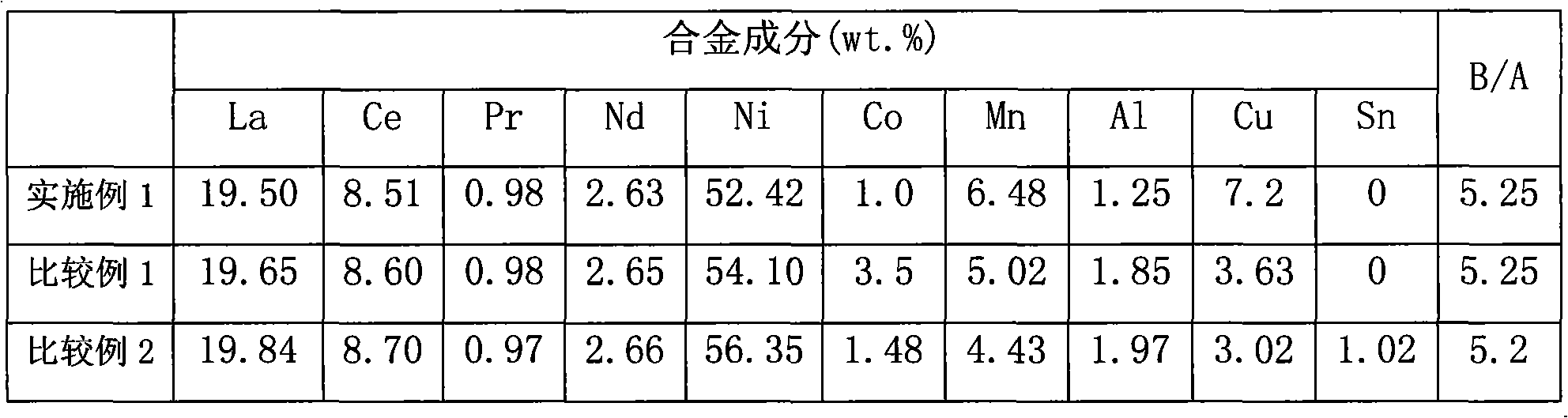

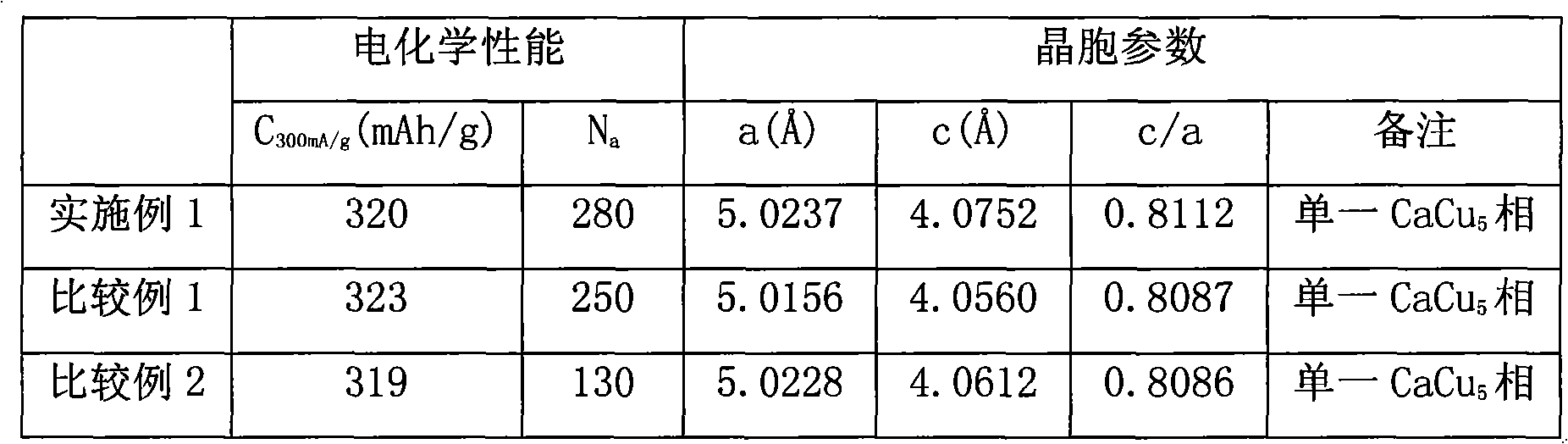

Embodiment 1

[0027] The design composition is La 0.62 Ce 0.27 PR 0.03 Nd 0.08 Ni 3.955 co 0.075 mn 0.52 Al 0.2 Cu 0.5 , according to the weight percentage of the composition shown, the prepared raw materials are placed in a vacuum induction quenching furnace, vacuumed and then filled with argon for protection, and then induction heating and melting is carried out at a melting temperature of 1300-1600 ° C, followed by casting Rapid cooling is carried out on a high-speed rotating copper roller with internal cooling water to obtain alloy flakes with a thickness of 0.1-0.3mm. The obtained alloy flakes are kept at 1000°C for 6.5 hours. After cooling, alloy powders with a particle size of less than 140 mesh are produced.

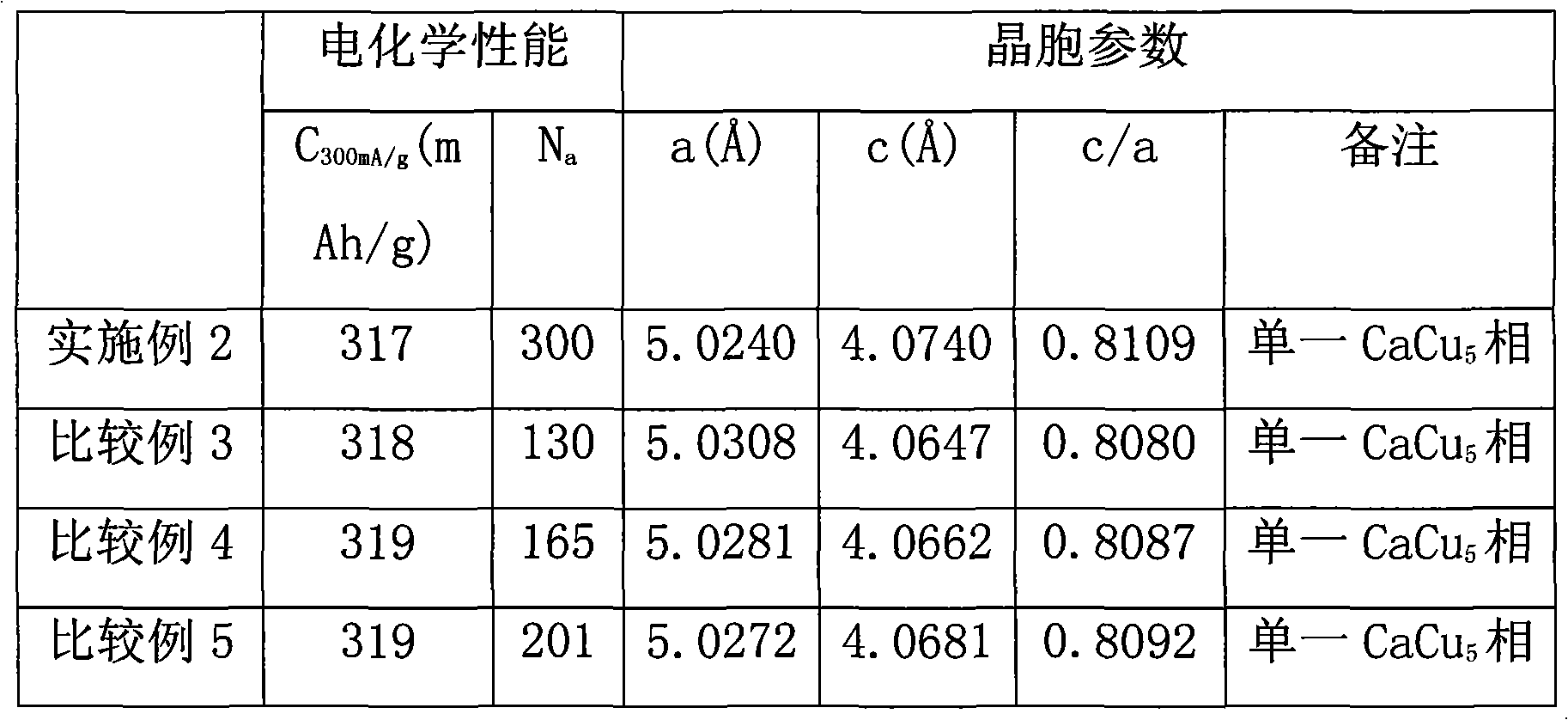

Embodiment 2

[0044] The design composition is La 0.634 Ce 0.257 PR 0.027 Nd 0.082 Ni 3.805 co 0.075 mn 0.52 Al 0.25 Cu 0.6 , except that the design components are different from embodiment 1, other are the same as embodiment 1.

Embodiment 3

[0056] The design composition is La 0.634 Ce 0.257 PR 0.027 Nd 0.082 Ni 3.675 co 0.075 mn 0.65 Al 0.05 Cu 0.8 , heat treatment process is 960 ℃ of insulation 6.5 hours, except that, others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com