Method and device for preparing synthetic natural gas

A technology for synthesizing natural gas and gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc. It can solve the problem of product gas back-mixing into raw material gas, achieve the effects of reducing high-temperature carbon deposition, convenient operation, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] The present invention will be described in further detail below in conjunction with some specific examples.

[0032] However, this should not be construed as limiting the scope of the above subject matter of the present invention to the following examples.

Embodiment 1

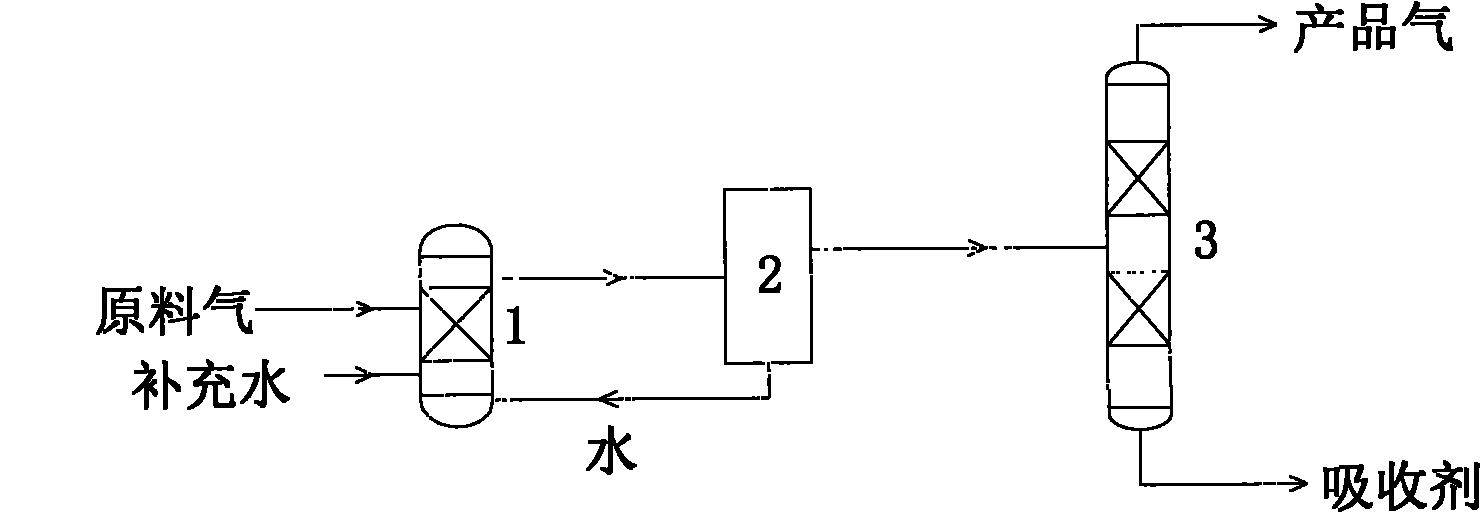

[0034] The crude gas obtained after the Lurgi coal gasifier is used as the raw material, and the main components are shown in the table below. The crude gas enters the reactor 1 (tank reactor) at 1Kmol / hr, the circulation rate of water in the reactor is maintained at 50Kmol / hr, the reaction temperature is 250°C, the pressure is 5.0MPa, and the catalyst is Ni / Al 2 o 3 The methanation catalyst separates water through the condensation separator 2, and removes CO with the CaO removal tower 3 2 The product gas composition and flow rate are shown in the table below:

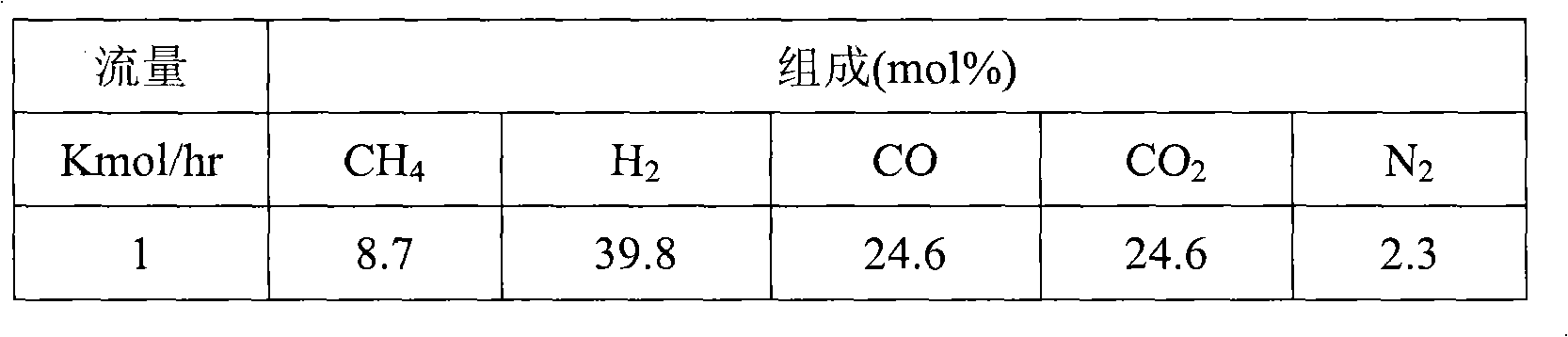

[0035] Table 1 Composition table of feed gas

[0036]

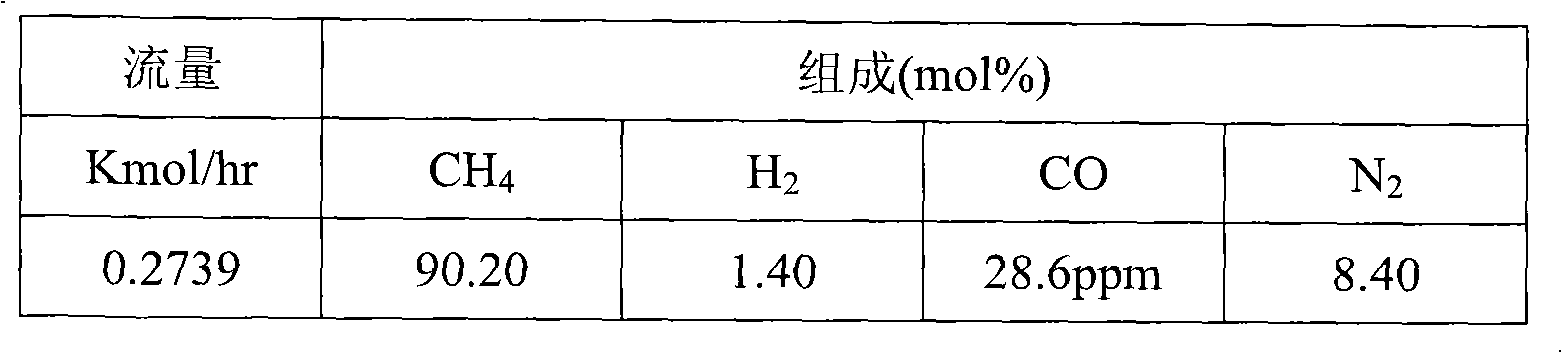

[0037] Table 2 Product Gas Composition Table

[0038]

Embodiment 2

[0040]The crude gas obtained after the Shell coal gasifier is used as the raw material, and the main components are shown in the table below. The raw gas is passed into the reactor 1 at a rate of 1Kmol / hr, the circulation rate of water in the reactor is maintained at 60Kmol / hr, the reaction temperature is 255°C, and the pressure is 5.5MPa. All the other conditions are as shown in Example 1. After separating water and removing CO 2 The product gas composition and flow rate are shown in the table below:

[0041] Table 3 Feed gas composition table

[0042]

[0043] Table 4 Product Gas Composition Table

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com