Ironing machine drying drum employing gas and infrared ray for heating

An infrared heating and ironing machine technology, which is applied in ironing machines, washing devices, textiles and papermaking, etc., can solve the problems of uneven heating of the flame direct injection drying cylinder, and achieves improved ironing efficiency, improved use environment, and improved use of handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure of the gas-fired infrared heating ironing machine drying cylinder of the present invention will be further described in detail below in conjunction with specific drawings. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

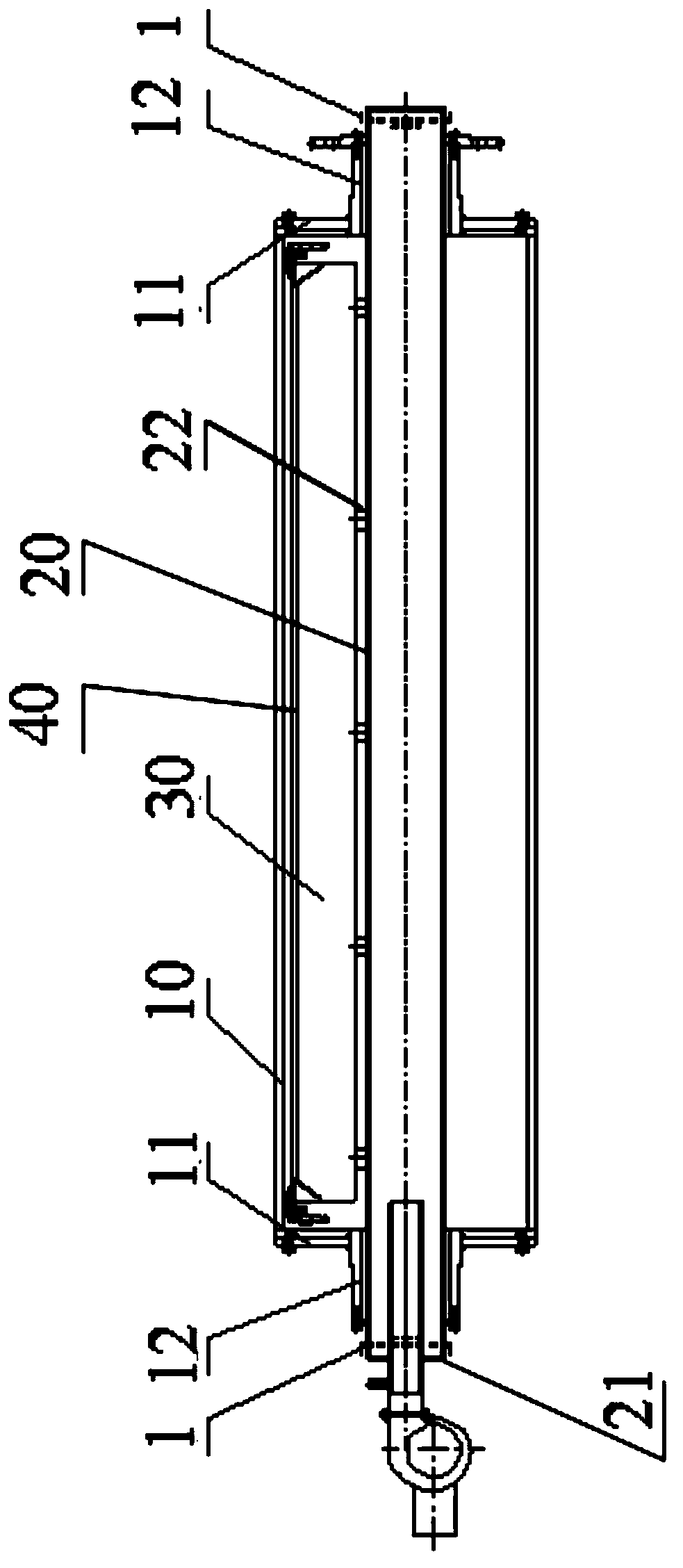

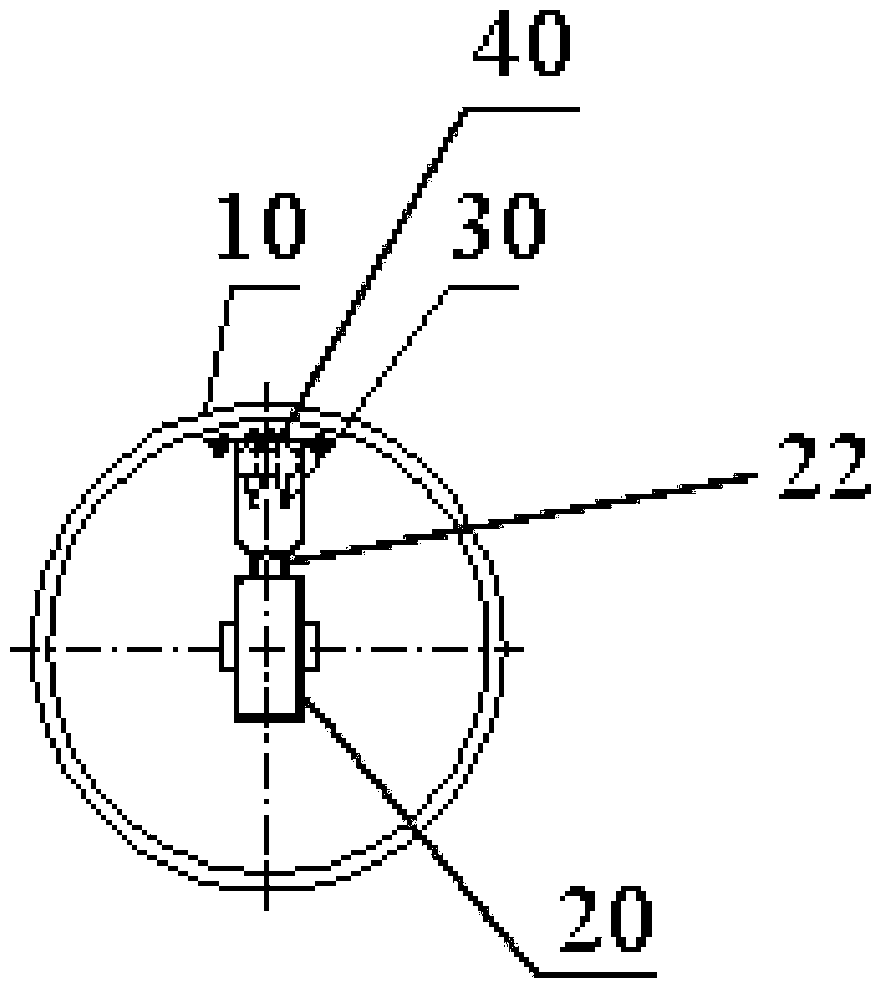

[0020] Such as figure 1 with figure 2 Shown, the ironing machine drying cylinder structure of gas infrared heating of the present invention comprises:

[0021] The cylinder body 10 is provided with connecting flanges 11 and hollow shafts 12 at both ends for supporting the cylinder body 10 and inputting rotational power;

[0022] The air supply square pipe 20 is arranged inside the cylinder body 10, and the two ends protrude from the hollow shaft 12 provided at the two ends 21 of the cylinder body 10, and is fixed on the ironing machine frame (not shown) through the support plate 1 ;

[0023] The infrared burner 30 is suspended i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com