A kind of nickel-aluminum co-doped trimanganese tetraoxide and preparation method thereof

A technology of trimanganese tetraoxide and trimanganese tetraoxide material, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of microscopic segregation of nickel and manganese, low capacity, uneven mixing of trimanganese tetraoxide, etc. Achieve the effect of large specific surface area, high activity and accurate stoichiometric ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of nickel-aluminum co-doped trimanganese tetraoxide of the present invention comprises the following steps:

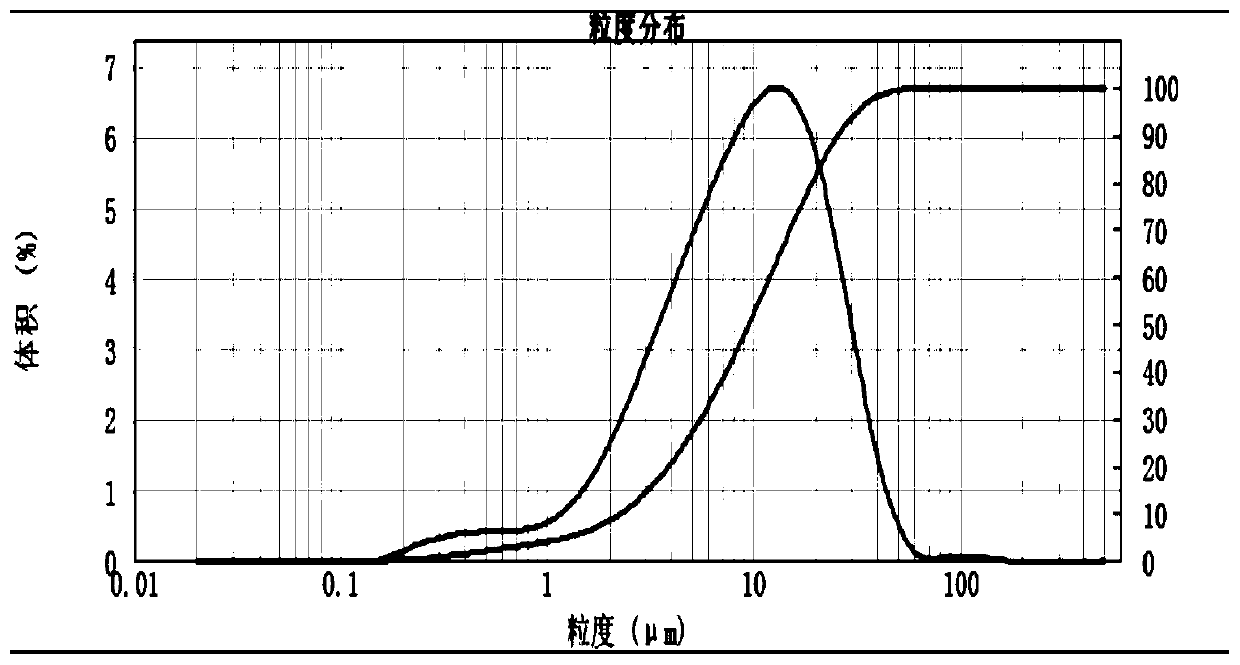

[0045] (1) the particle size D 50 Add manganese metal powder of 200 μm into the aqueous solution to make a slurry, then add nickel sulfate and aluminum chloride, and stir to obtain a mixed slurry; the three raw materials of manganese metal powder, nickel sulfate and aluminum chloride are prepared according to the element molar ratio n(Mn ):n(Ni):n(Al)=0.73:0.25:0.02 for proportioning;

[0046] (2) Add ammonium acetate, sodium hydroxide and ammoniacal liquor to the mixed slurry after step (1) successively, control the stirring speed of the reaction process to be 700rmp, the reaction temperature is 55°C, the reaction time is 20h, and the pH value is controlled at 10.0 , the solid-to-liquid ratio is 1:5, and the manganese hydroxide slurry doped with nickel and aluminum is obtained from the reaction; wherein, the concentration of ammonium aceta...

Embodiment 2

[0051] A preparation method of nickel-aluminum co-doped trimanganese tetraoxide of the present invention comprises the following steps:

[0052] (1) the particle size D 50 Add manganese metal powder of 200 μm into the aqueous solution to make a slurry, then add nickel acetate and aluminum nitrate, and stir to obtain a mixed slurry; the three raw materials of manganese metal powder, nickel acetate and aluminum nitrate are according to the element molar ratio n (Mn): n(Ni):n(Al)=0.75:0.22:0.03 for proportioning;

[0053] (2) Ammonium bicarbonate, sodium hydroxide and ammoniacal liquor are added successively in the mixed slurry after step (1), the stirring speed of controlling the reaction process is 900rmp, the reaction temperature is 70°C, the reaction time is 15h, and the pH value is controlled at 9.0, the solid-to-liquid ratio is 1:4, and the manganese hydroxide slurry doped with nickel and aluminum is obtained from the reaction; among them, the concentration of ammonium bic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com