Preparation method of hollow tubular lithium-rich manganese-based positive electrode material

A lithium-rich manganese-based, cathode material technology, used in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of cumbersome particle collection process, inability to meet industrial production requirements, etc., achieve excellent cycle performance, and facilitate industrialization. Production, stoichiometric accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

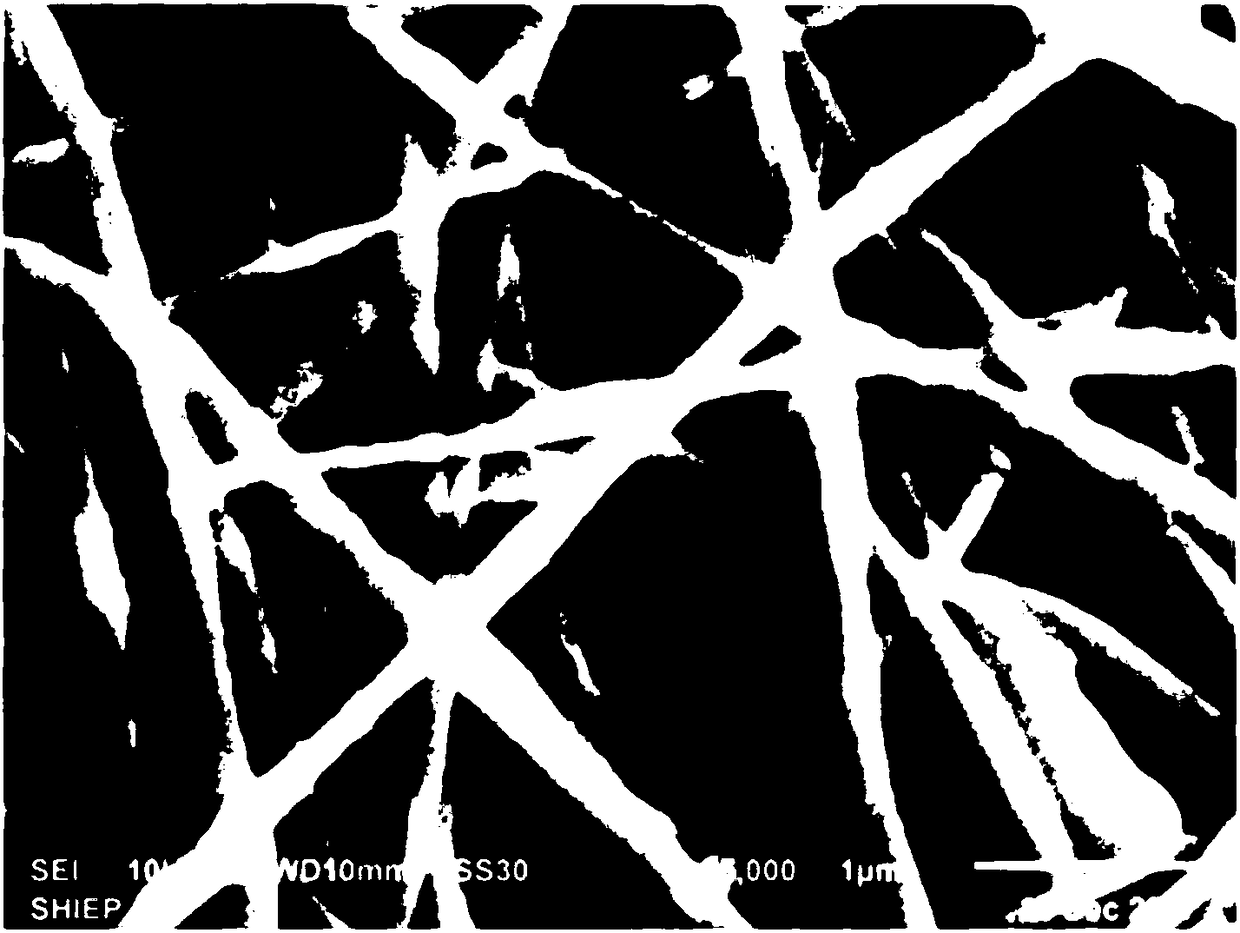

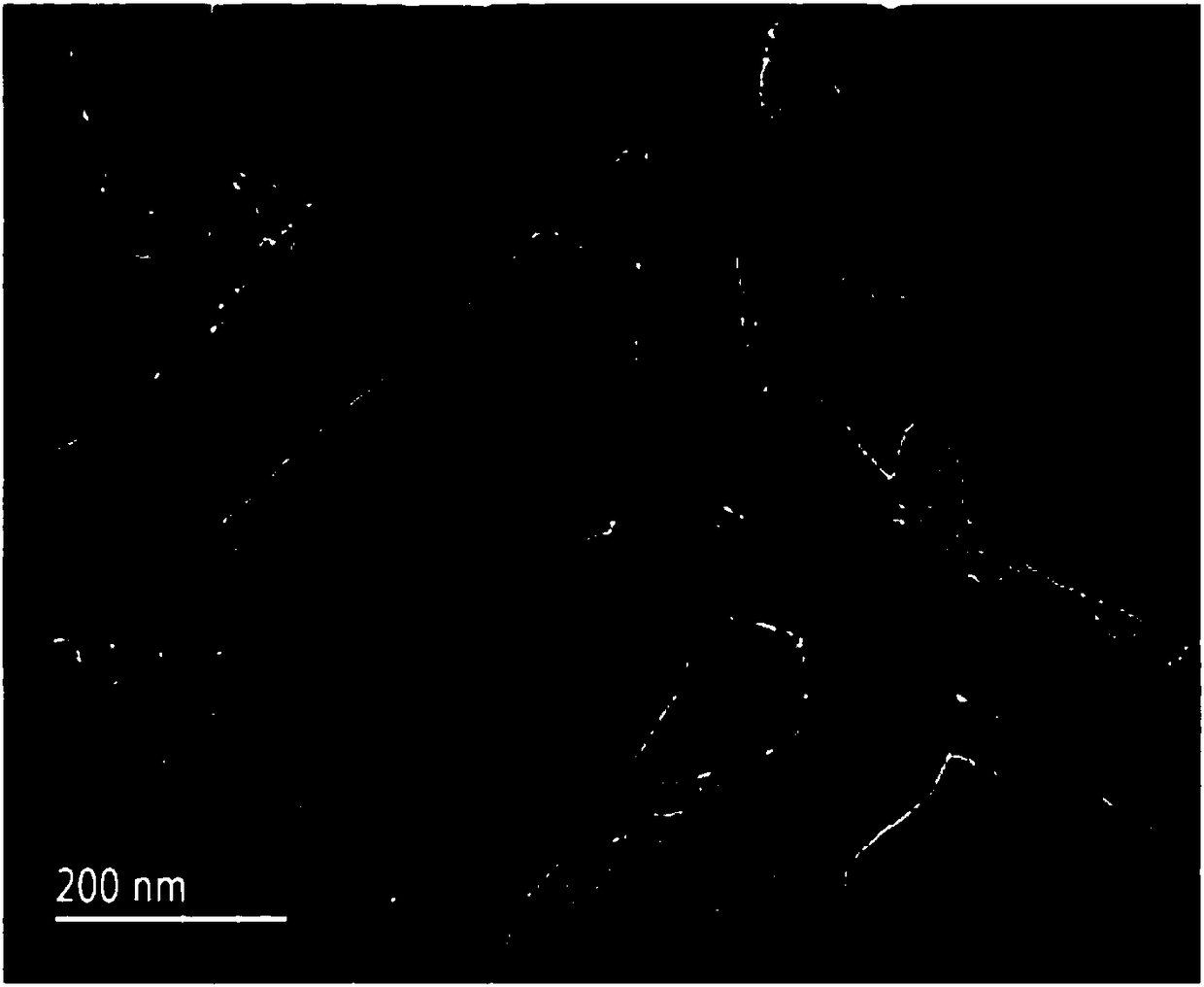

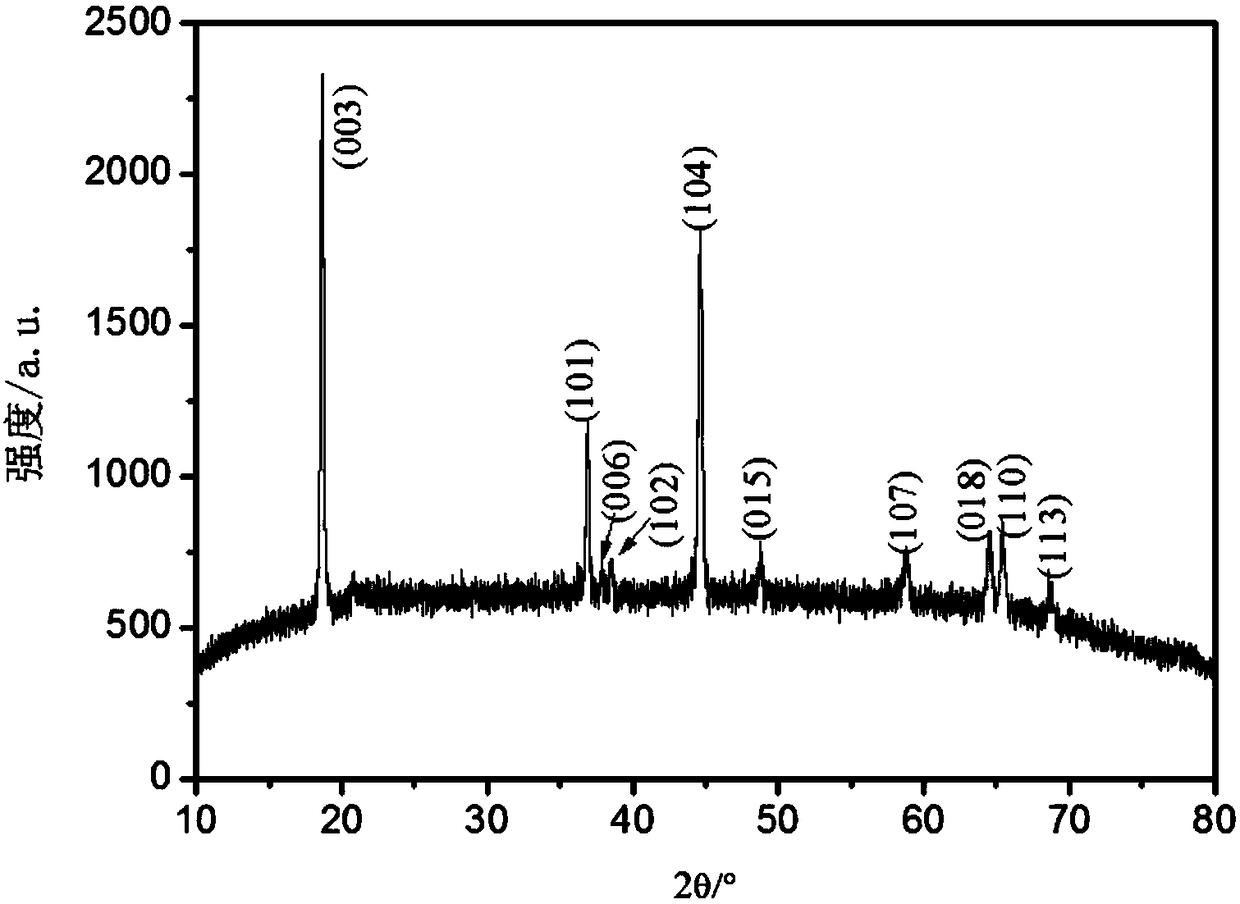

[0039] A method for preparing a hollow tubular lithium-rich manganese-based positive electrode material, the lithium-rich manganese-based positive electrode material contains Li, Mn, Ni, Co and O elements, and its molecular formula is Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 .

[0040] The preparation method of the above-mentioned lithium-rich manganese-based positive electrode material specifically includes the following steps:

[0041] 1) Dissolve 4g of polymethyl methacrylate in 10mL of N,N-dimethylformamide, stir and dissolve in a water bath at 50°C to obtain spinning solution A;

[0042] 2) Dissolve 2g of polyacrylonitrile in 10mL of N,N-dimethylformamide, stir and dissolve at room temperature, and dissolve soluble 1.2855g of lithium acetate, 1.3235g of manganese acetate, 0.3235g of nickel acetate and 0.3238g of cobalt acetate in In N,N-dimethylformamide, after the two solutions are mixed, spinning solution B is obtained;

[0043] 3) Adopt the coaxial electrospinning proc...

Embodiment 2

[0059] A method for preparing a hollow tubular lithium-rich manganese-based positive electrode material, the lithium-rich manganese-based positive electrode material contains Li, Mn, Ni, Co and O elements, and its molecular formula is Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 .

[0060] The preparation method of the above-mentioned lithium-rich manganese-based positive electrode material specifically includes the following steps:

[0061] 1) Dissolve 4g of polymethyl methacrylate in 10mL of N,N-dimethylformamide, stir and dissolve in a water bath at 50°C to obtain spinning solution A;

[0062] 2) Dissolve 2g of polyacrylonitrile in 10mL of N,N-dimethylformamide, stir and dissolve at room temperature, and dissolve soluble 1.2855g of lithium acetate, 1.3235g of manganese acetate, 0.3235g of nickel acetate and 0.3238g of cobalt acetate in In N,N-dimethylformamide, after the two solutions are mixed, spinning solution B is obtained;

[0063] 3) Adopt the coaxial electrospinning proc...

Embodiment 3

[0066] A method for preparing a hollow tubular lithium-rich manganese-based positive electrode material, the lithium-rich manganese-based positive electrode material contains Li, Mn, Ni, Co and O elements, and its molecular formula is Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 .

[0067] The preparation method of the above-mentioned lithium-rich manganese-based positive electrode material specifically includes the following steps:

[0068] 1) Dissolve 2g of polymethyl methacrylate in 10mL of N,N-dimethylformamide, stir and dissolve in a water bath at 50°C to obtain spinning solution A;

[0069] 2) Dissolve 2g of polyacrylonitrile in 10mL of N,N-dimethylformamide, stir and dissolve at room temperature, and dissolve soluble 1.2855g of lithium acetate, 1.3235g of manganese acetate, 0.3235g of nickel acetate and 0.3238g of cobalt acetate in In the organic solvent, after the two solutions are mixed, the spinning solution B is obtained;

[0070] 3) Adopt the coaxial electrospinning pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com