Copper-zinc-tin-sulfur micro/nano-fiber material and method for preparing same

A fiber material, copper-zinc-tin-sulfur technology, applied in the direction of fiber treatment, artificial filament of inorganic raw materials, textiles and papermaking, etc., to achieve the effect of accurate stoichiometric ratio, low impurity content and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

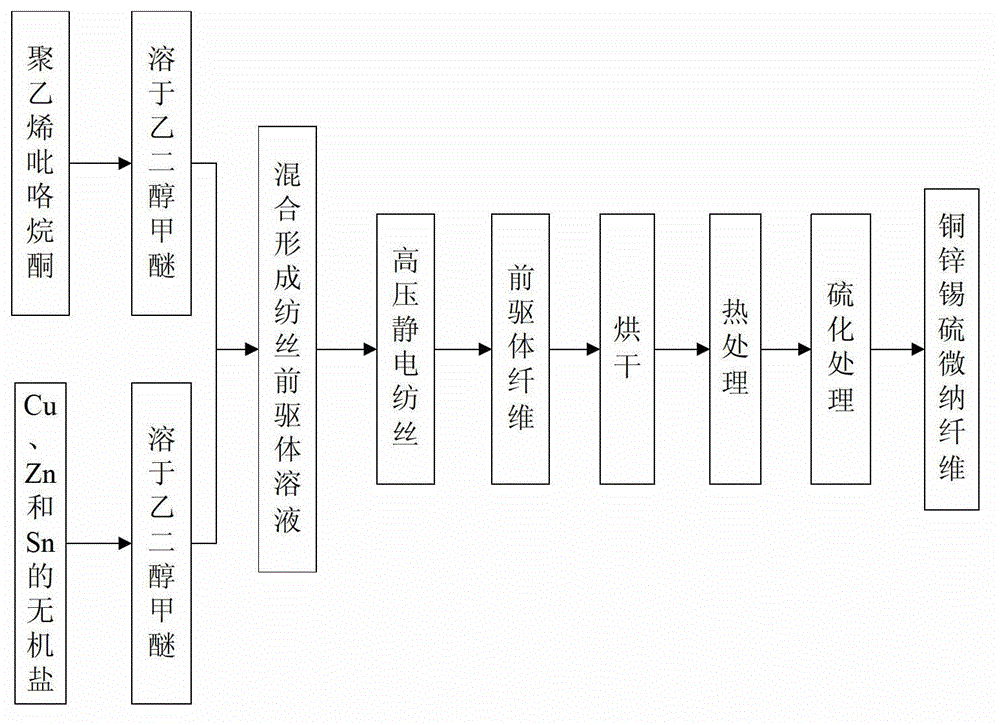

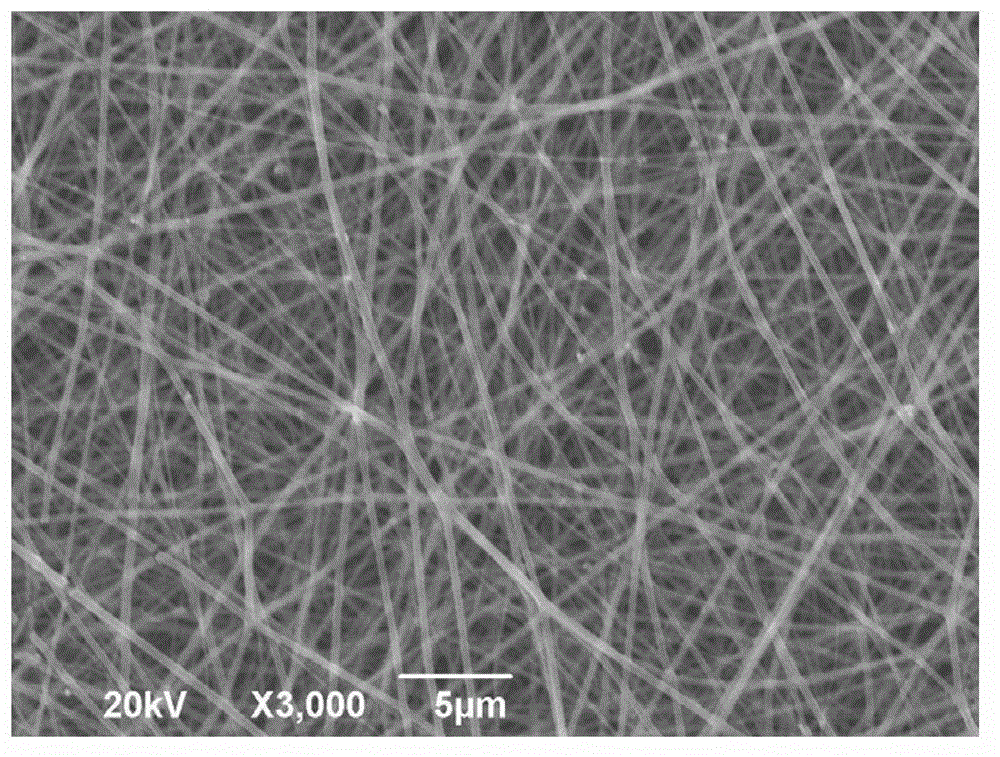

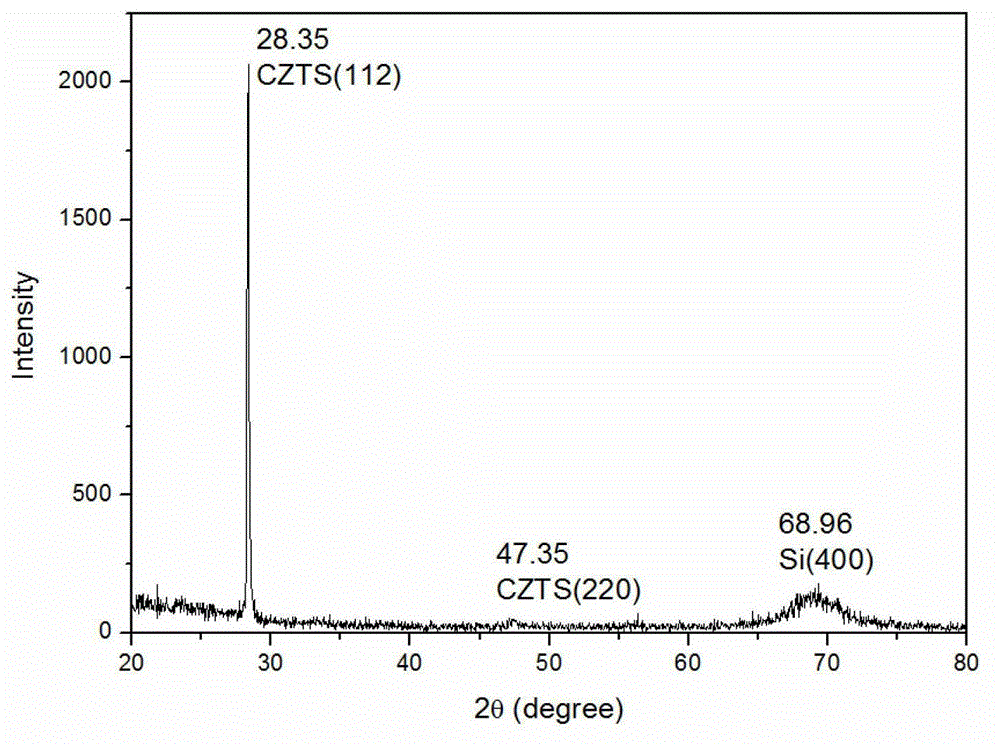

[0021] Cu(CH 3 COO) 2 ·H 2 O, Zn(CH 3 COO) 2 2H 2 O, SnCl 4 ·5H 2 O. PVP is dissolved in ethylene glycol methyl ether according to a certain ratio to prepare a precursor solution, wherein the molar ratio of each metal ion is Cu:Zn:Sn=2:1:1. The precursor micron fibers obtained by high-voltage electrospinning were successively passed through 2 In Ar gas, heat treatment at 450°C for 30 minutes, and finally vulcanization treatment at 500°C for 40 minutes to obtain the final CZTS micro-nanofibers. Its specific preparation process is as follows:

[0022] Step 1: Weigh 0.3993g of Cu(CH 3 COO) 2 ·H 2 O, 0.2195g of Zn(CH 3 COO) 2 2H 2 O. 5.81g of PVP was poured into a beaker, and 10ml of ethylene glycol methyl ether was added, and dissolved with magnetic stirring at room temperature to form a uniform solution A.

[0023] Step 2: Weigh 0.3506g of SnCl 4 ·5H 2 O in a beaker, add 2ml of ethylene glycol methyl ether to the beaker, and then add 0.64g of PVP, and ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com