Lithium-rich manganese-based layered lithium battery cathode material and preparation method thereof

A positive electrode material and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limiting the scale production and popularization of materials, the inability to accurately control material stoichiometry, and no major breakthrough in specific capacity. Accurate stoichiometric ratio, uniform product composition, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

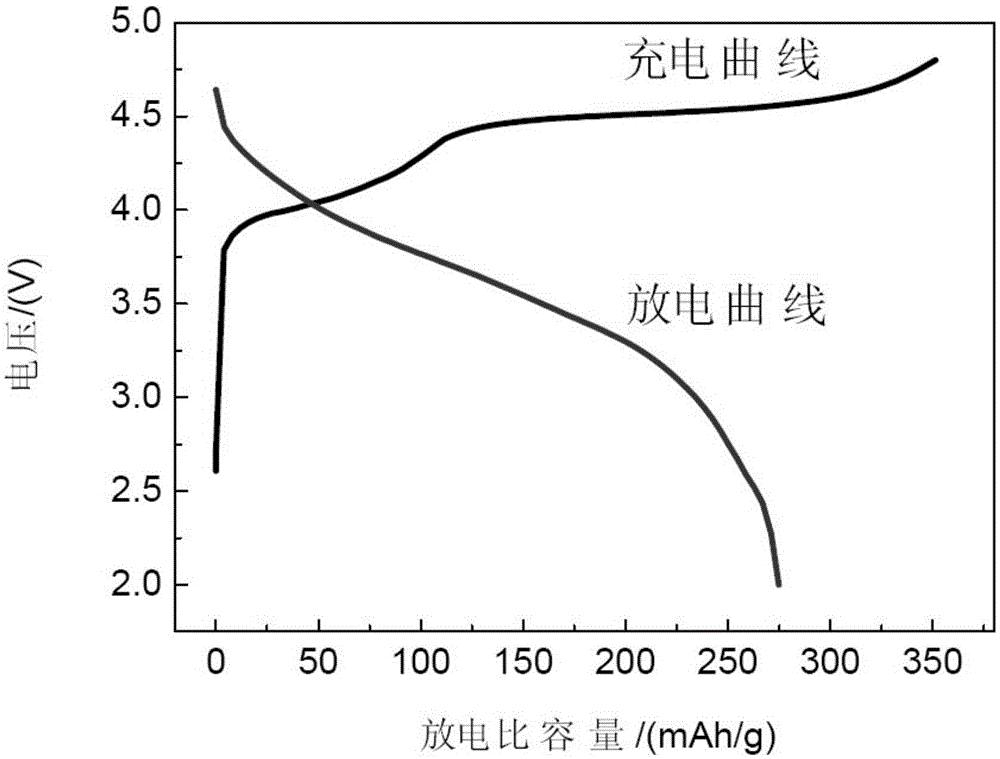

[0041] A lithium-rich manganese-based layered lithium battery positive electrode material of the present invention, the molecular formula of the positive electrode material is Li[Li 0.202 Ni 0.132 Co 0.13 Mn 0.536 ]O 2 , The D of the cathode material 50 At 15.253μm, the specific surface area is at 1.417m 2 / g, the discharge capacity reaches 274.8mAh / g at a charge-discharge current density of 12.5mA / g (see figure 1 ).

[0042] The above-mentioned lithium-rich manganese-based layered lithium battery cathode material Li[Li 0.202 Ni 0.132 Co 0.13 Mn 0.536 ]O 2 The preparation method specifically includes the following steps:

[0043] (1) Material preparation: lithium nitrate, nickel nitrate, cobalt nitrate and manganese nitrate to be used as raw materials, and polyacrylic acid and citric acid to be used as a composite chelating agent;

[0044] (2) Prepare a mixed solution: According to the weight ratio of each metal element in the molecular formula of the positive electrode material, the...

Embodiment 2

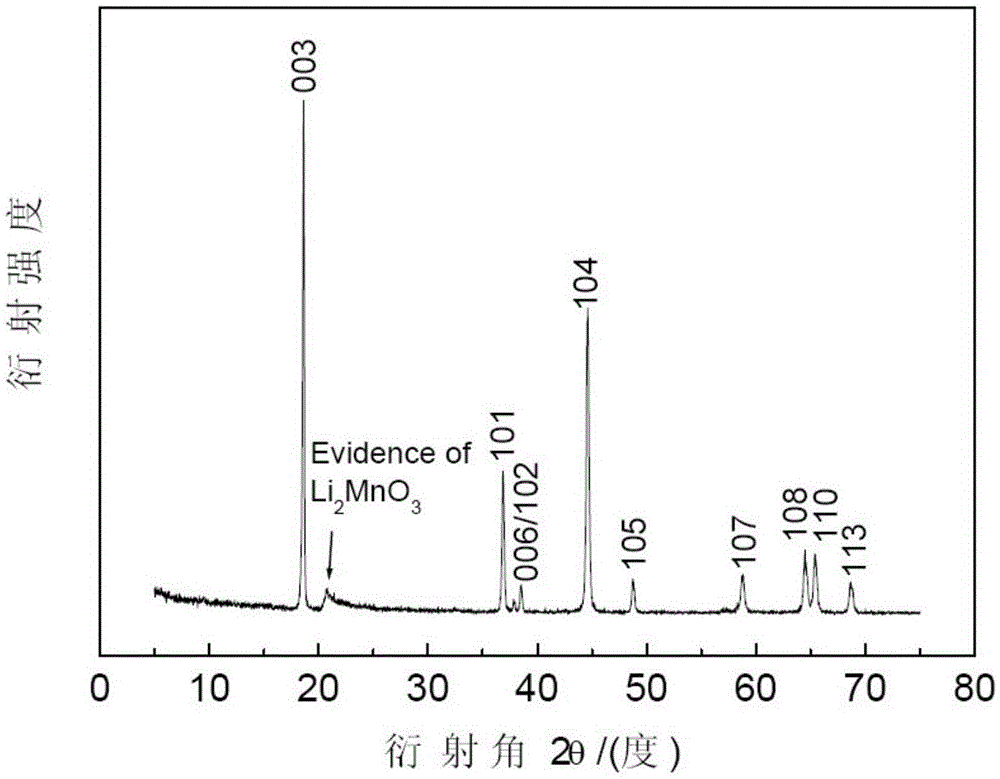

[0048] Kind of like figure 2 The lithium-rich manganese-based layered lithium battery cathode material of the present invention shown, the molecular formula of the cathode material is Li[Li 0.202 Ni 0.132 Co 0.13 Mn 0.536 ]O 2 , The D of the cathode material 50 At 14.395μm, the specific surface area is at 1.398m 2 / g, the discharge capacity reaches 242.3mAh / g at a charge-discharge current density of 12.5mA / g.

[0049] The above-mentioned lithium-rich manganese-based layered lithium battery cathode material Li[Li 0.202 Ni 0.132 Co 0.13 Mn 0.536 ]O 2 The preparation method specifically includes the following steps:

[0050] (1) Material preparation: lithium nitrate, nickel nitrate, cobalt nitrate and manganese nitrate to be used as raw materials, and polyacrylic acid and citric acid to be used as a composite chelating agent;

[0051] (2) Prepare a mixed solution: According to the weight ratio of each metal element in the molecular formula of the positive electrode material, the raw mat...

Embodiment 3

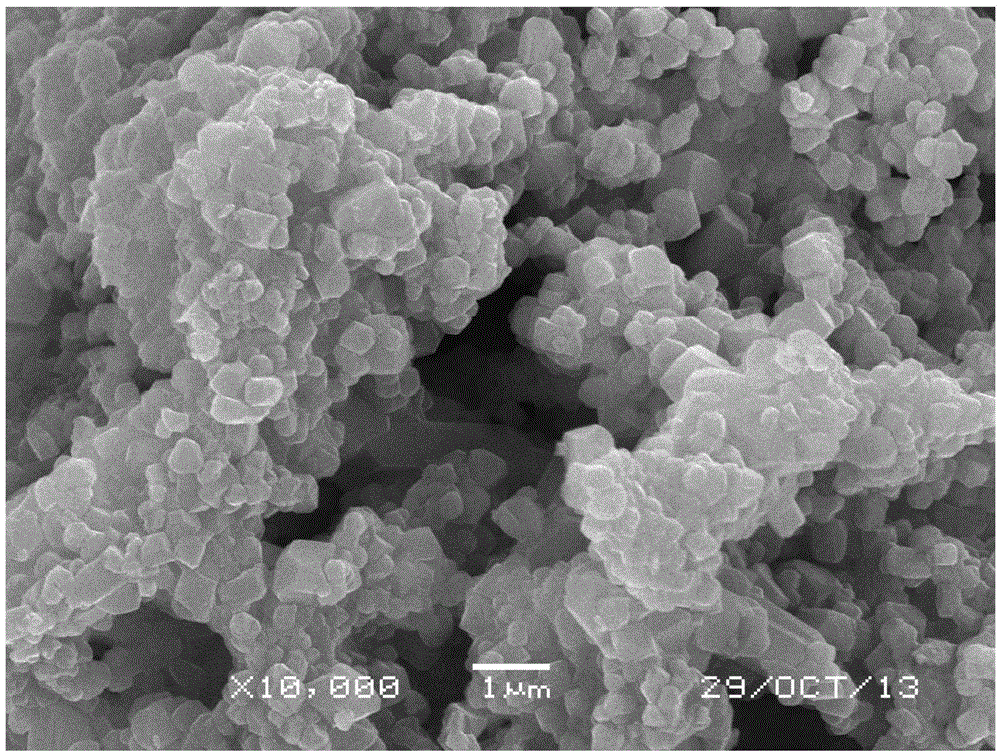

[0056] Kind of like image 3 The lithium-rich manganese-based layered lithium battery cathode material of the present invention shown, the molecular formula of the cathode material is Li[Li 0.06 Ni 0.145 Co 0.145 Mn 0.650 ]O 2 , The D of the cathode material 50 At 15.789μm, the specific surface area is 1.528m 2 / g, the discharge capacity reaches 230.0mAh / g at a charge-discharge current density of 12.5mA / g.

[0057] The above-mentioned lithium-rich manganese-based layered lithium battery cathode material Li[Li 0.06 Ni 0.145 Co 0.145 Mn 0.650 ]O 2 The preparation method specifically includes the following steps:

[0058] (1) Material preparation: lithium nitrate, nickel nitrate, cobalt nitrate and manganese nitrate to be used as raw materials, and polyacrylic acid and citric acid to be used as a composite chelating agent;

[0059] (2) Prepare the mixed solution: According to the measurement ratio of the metal elements in the molecular formula of the positive electrode material, the raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com