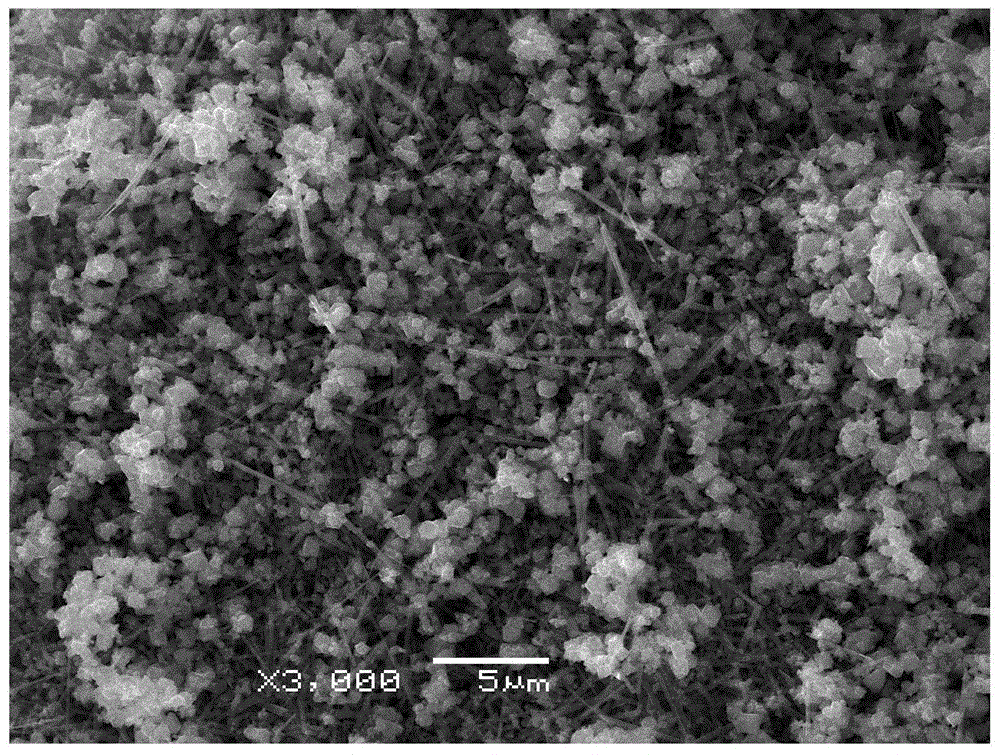

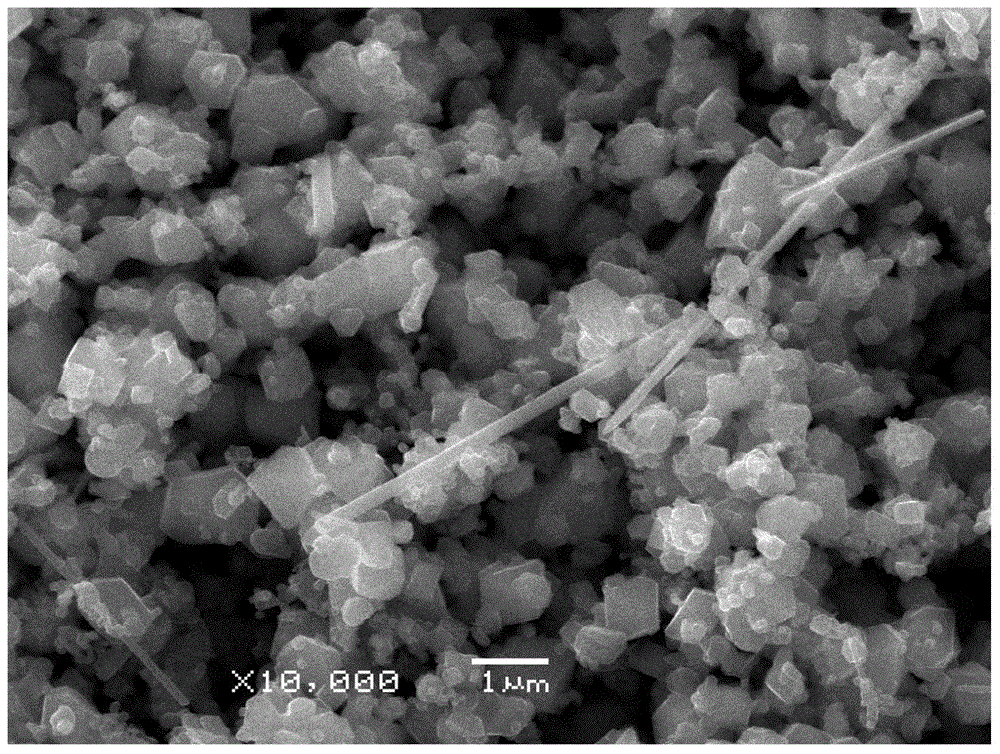

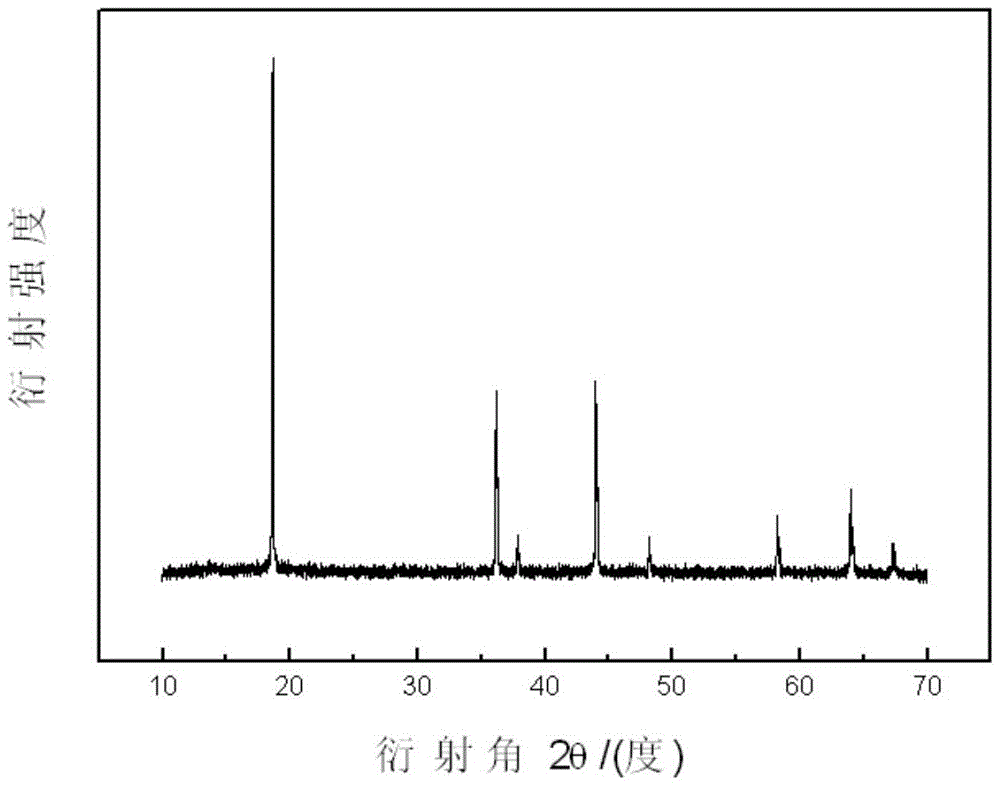

A kind of preparation method of acicular spinel type lithium manganese oxide cathode material

A type of lithium manganate and positive electrode material technology, applied in the field of preparation of lithium ion battery positive electrode materials, can solve the problems of difficult and difficult product morphology, and achieve easy control of particle size and shape, low equipment requirements, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of the needle-shaped spinel-type lithium manganate cathode material of the present invention includes the following steps:

[0046] (1) Prepare lithium hydroxide as a lithium source, potassium permanganate as a manganese source, and sodium sulfite as a strong reducing agent, in which potassium permanganate is used as both a manganese raw material and a strong oxidant;

[0047] (2) The potassium permanganate and lithium hydroxide obtained in step (1) are added to the aqueous solution and mixed uniformly, and then the mixed aqueous solution is added to the reactor, and sodium sulfite is added to the reactor. The molar ratio of the reaction amount of lithium hydroxide, potassium permanganate and sodium sulfite is n(LiOH): n(KMnO 4 ):n(Na 2 SO 4 )=3:2:3.5, the reaction temperature is 84°C, the reaction time is 3 hours, and the stirring method is magnetic stirring; the specific reactions that occur during the reaction are as follows: (1) 2KMnO 4 +3Na 2 SO 3 +H...

Embodiment 2

[0053] A preparation method of the needle-shaped spinel-type lithium manganate cathode material of the present invention includes the following steps:

[0054] (1) Prepare lithium hydroxide as a lithium source, potassium permanganate as a manganese source, and sodium sulfite as a strong reducing agent, in which potassium permanganate is used as both a manganese raw material and a strong oxidant;

[0055] (2) The potassium permanganate and lithium hydroxide obtained in step (1) are added to the aqueous solution and mixed uniformly, and then the mixed aqueous solution is added to the reactor, and sodium sulfite is added to the reactor. The molar ratio of the reaction amount of lithium hydroxide, potassium permanganate and sodium sulfite is n(LiOH): n(KMnO 4 ):n(Na 2 SO 4 )=4:2:3.5, the reaction temperature is 64°C, the reaction time is 8 hours, and the stirring method is magnetic stirring; the specific reactions that occur during the reaction are as follows: (1) 2KMnO 4 +3Na 2 SO 3 +H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com