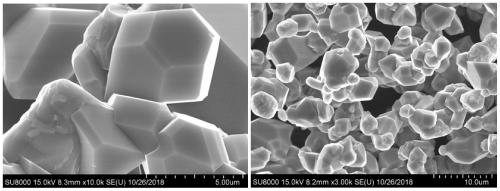

Preparation method of sharpened monocrystal high-voltage spinel lithium nickel manganese oxide cathode material

A lithium nickel manganese oxide and cathode material technology, applied in the field of lithium-ion battery materials, can solve the problems of reduced electrochemical performance, many structural defects, and increased side reactions, so as to improve cycle performance, avoid raw material splashing, and reduce manganese dissolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

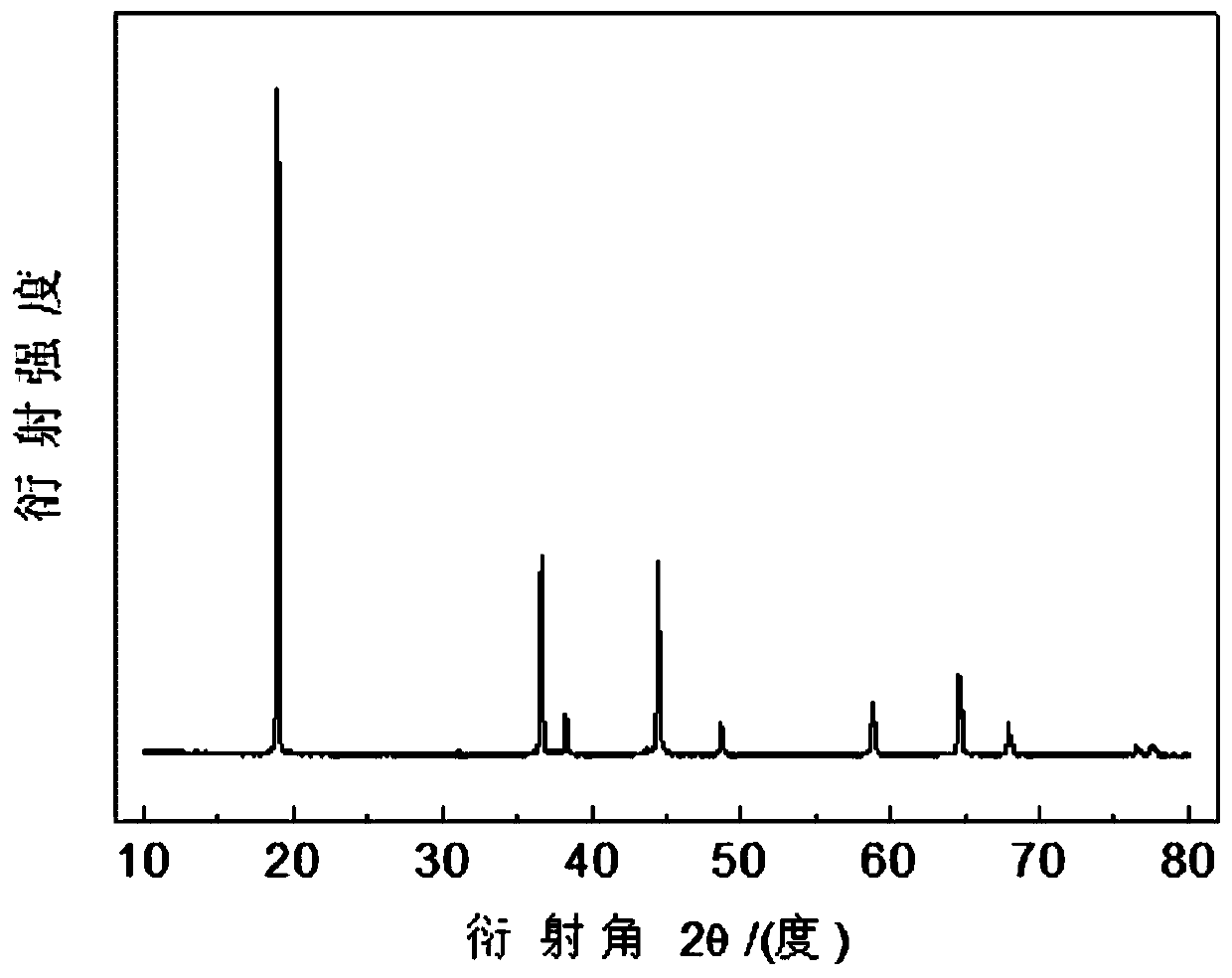

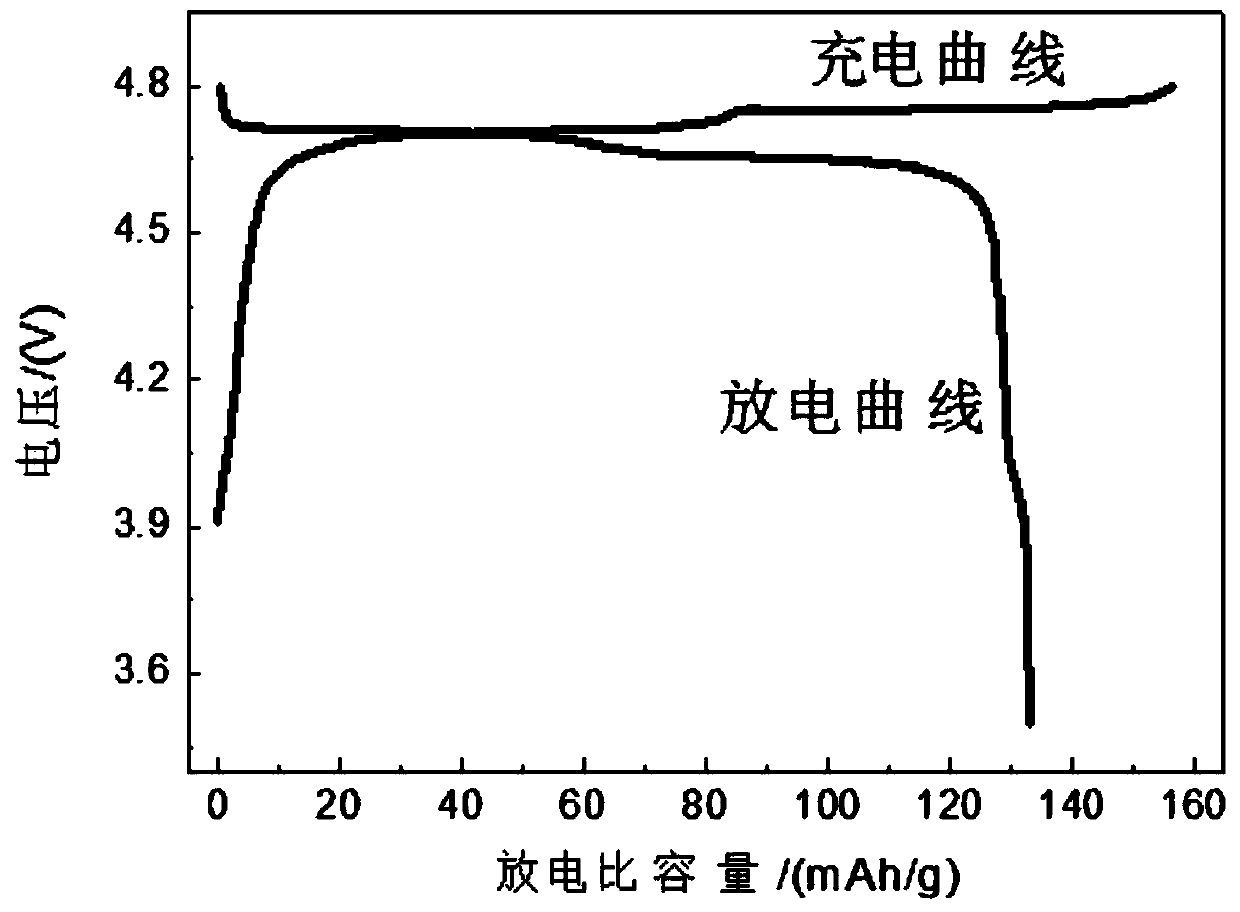

Embodiment 1

[0047] A preparation method of the sharpened single crystal high-voltage spinel lithium nickel manganese oxide positive electrode material of the present invention, the specific steps are as follows:

[0048] (1) Material preparation

[0049] Lithium acetate, nickel nitrate and manganese oxalate to be used as raw material, AlF to be used as dopant 3 , Li ready to be used as a flux 2 MoO 4 And glycine as fuel; The raw material is the molecular formula LiNi according to the target product to be prepared 0.5 mn 1.5 o 4 Prepare for weighing, AlF 3 The weight is 0.3wt% of the weight of the spinel lithium nickel manganese oxide positive electrode material, Li 2 MoO 4 Add-on is 2wt% of spinel lithium nickel manganese oxide positive electrode material weight; The total molar weight of raw material and the molar ratio n(M) / n(fuel)=3 of aminoacetic acid, wherein, n(M) refers to each The sum of the moles of metal elements lithium, nickel and manganese;

[0050] (2) Mixing

[00...

Embodiment 2

[0059] A preparation method of the sharpened single crystal high-voltage spinel lithium nickel manganese oxide positive electrode material of the present invention, the specific steps are as follows:

[0060] (1) Material preparation

[0061] Lithium nitrate, nickel acetate and manganese sulfate prepared as raw materials, AlF prepared as dopant 3 , Li ready to be used as a flux 2 MoO 4 And glycine as fuel; Wherein, raw material is the molecular formula LiNi according to the target product to be prepared 0.5 mn 1.5 o 4 Prepare for weighing, AlF 3 The weight is 0.5wt% of the weight of the spinel lithium nickel manganese oxide positive electrode material, Li 2 MoO 4 Add-on is 3wt% of spinel lithium nickel manganese oxide positive electrode material weight; The mol ratio n (M) / n (fuel)=5 of raw material and glycine, wherein, n (M) refers to each metal element lithium, The sum of the moles of nickel and manganese;

[0062] (2) Mixing

[0063] The materials prepared in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com