Preparation method of solid oxide electrolytic cell NiO-YSZ hydrogen electrode powder

A solid oxide, electrolytic cell technology, applied in battery electrodes, electrodes, electrolysis process, etc., can solve the problems of inaccurate stoichiometric ratio of products, poor bonding of NiO and YSZ, segregation of metal ions, etc., to achieve accurate stoichiometric ratio, Strong catalytic activity and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention proposes a novel, high-performance method for preparing NiO-YSZ hydrogen electrode powder for solid oxide electrolytic cells. In this method, nickel nitrate is used as nickel source, ammonia water is used as precipitant, and YSZ powder is used as the core wrapped by precipitation. The in-situ synthesis method efficiently prepares the powder, and the steps are as follows:

[0021] (1) Prepare 0.3-1mol / L nickel nitrate solution with nickel nitrate hexahydrate and deionized water, then add the required amount of YSZ powder to the nickel nitrate solution, and put it in a water bath at 15-50°C, ultrasonic vibration and high-speed stirring conditions , the YSZ particles are uniformly dispersed in the solution, as Ni(OH) 2 For the core of precipitation attachment, the use of a thicker solution is to ensure the supersaturation of the system, so that Ni(OH) 2 The precipitated particles are fine;

[0022] (2) Drop the precipitant to adjust the pH value to ...

Embodiment 1

[0027] Example 1: In situ synthesis of NiO-YSZ powder by ammonia precipitation

[0028] Weigh 72.70g Ni(NO 3 ) 2 ·6H 2 0, be mixed with the nickel nitrate solution of 0.5mol / L with deionized water, then add 12.00g YSZ powder (Tosoh 8YSZ in Japan) in the nickel nitrate solution, after ultrasonic treatment 15 minutes, in 20 ℃ of water baths and the magnetic stirring Ammonia water was added dropwise to the mixture under conditions to adjust the pH value of the solution to 7.6, resulting in a light green precipitate. After the dropwise addition of ammonia water, adjust the temperature of the water bath to 70°C, let the precipitate continue to mature for 40 minutes, then filter, wash, and dry the matured precipitate at 105°C, and finally put it in a muffle furnace and roast at 800°C for 2 hours to obtain 24.66 g NiO-YSZ powder. The mass ratio of NiO and YSZ in the powder is about 1:1.

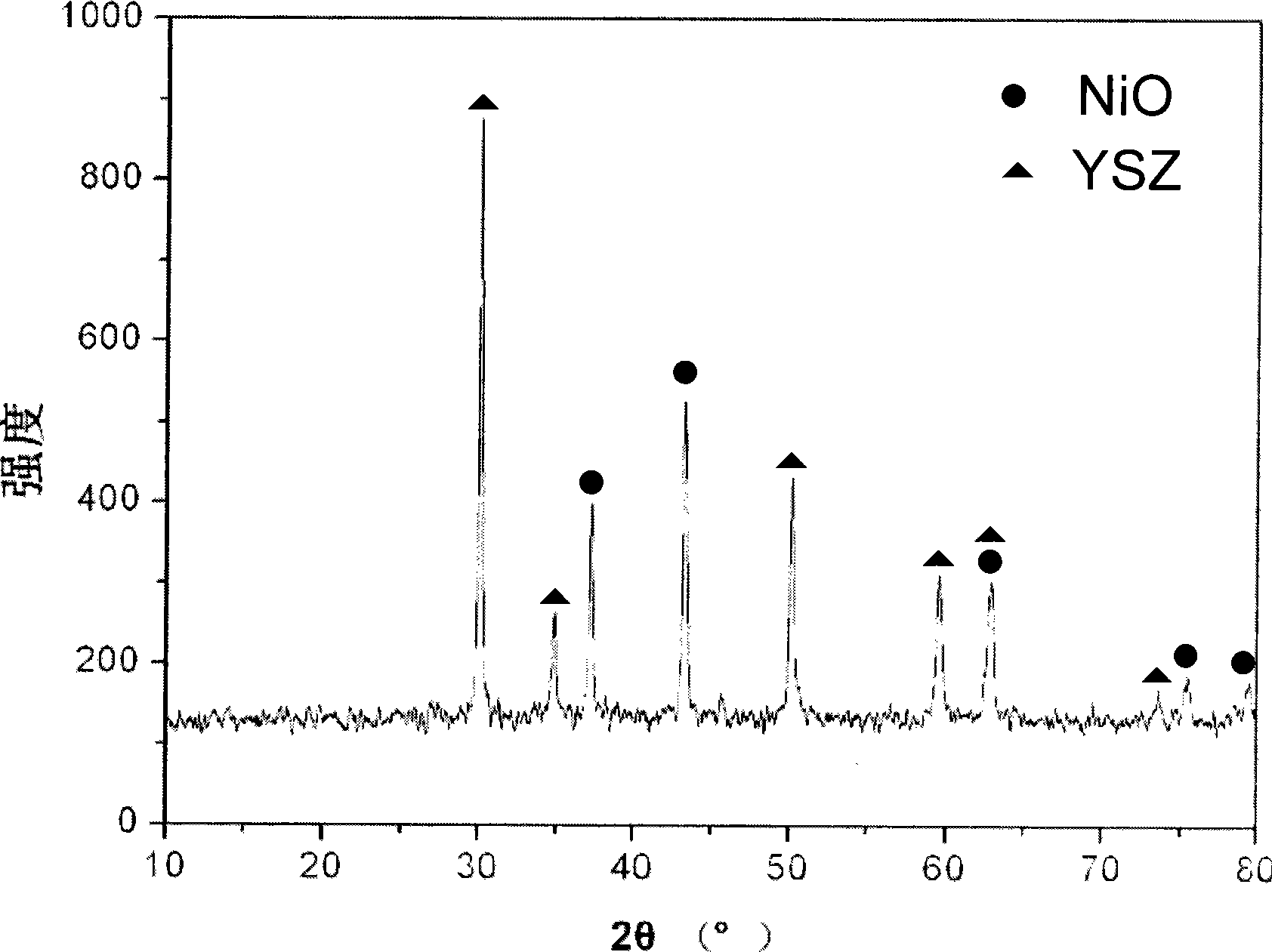

[0029] figure 1 It is the X-ray diffraction pattern (XRD) of NiO-YSZ powder synthesized in...

Embodiment 2

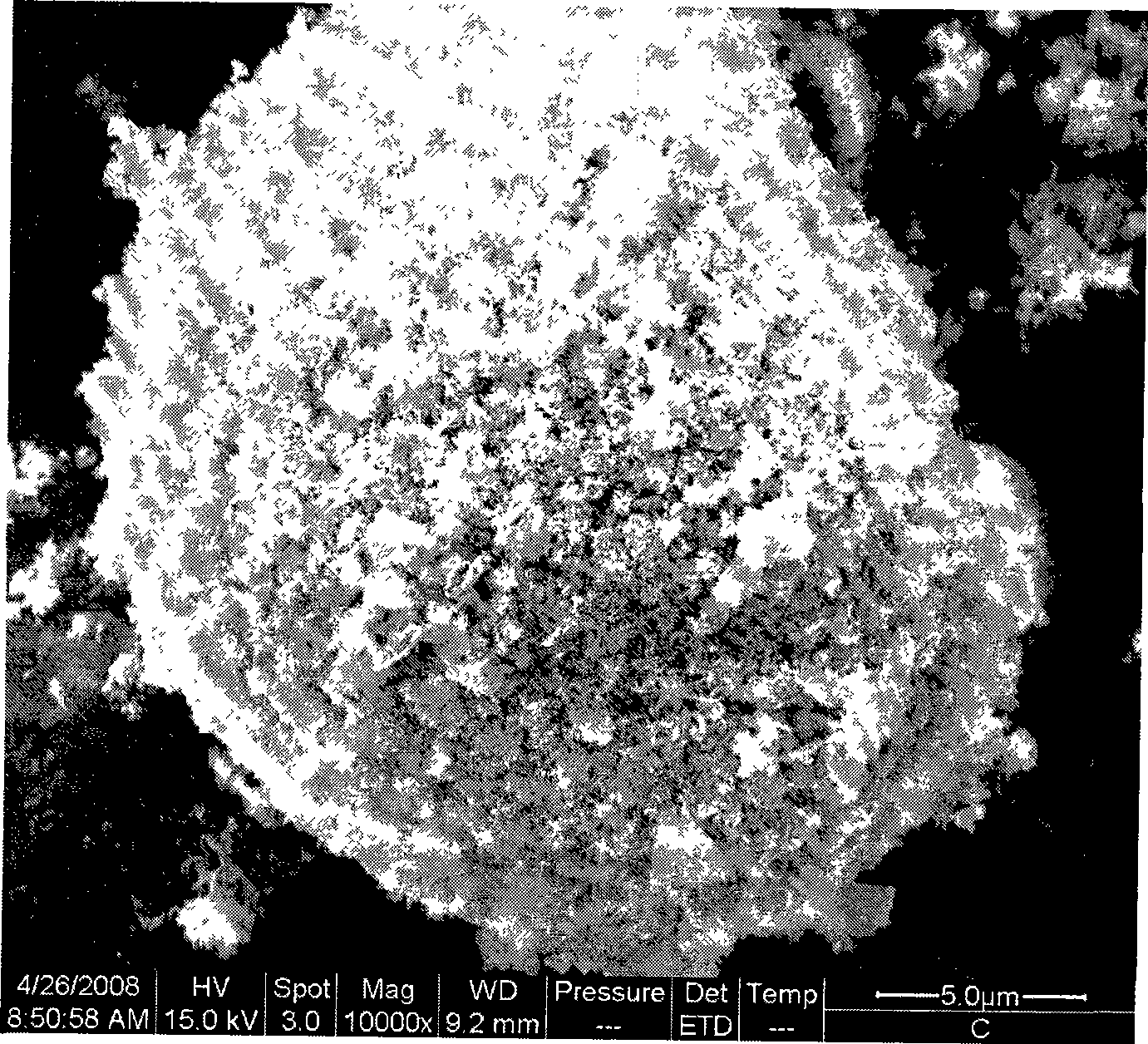

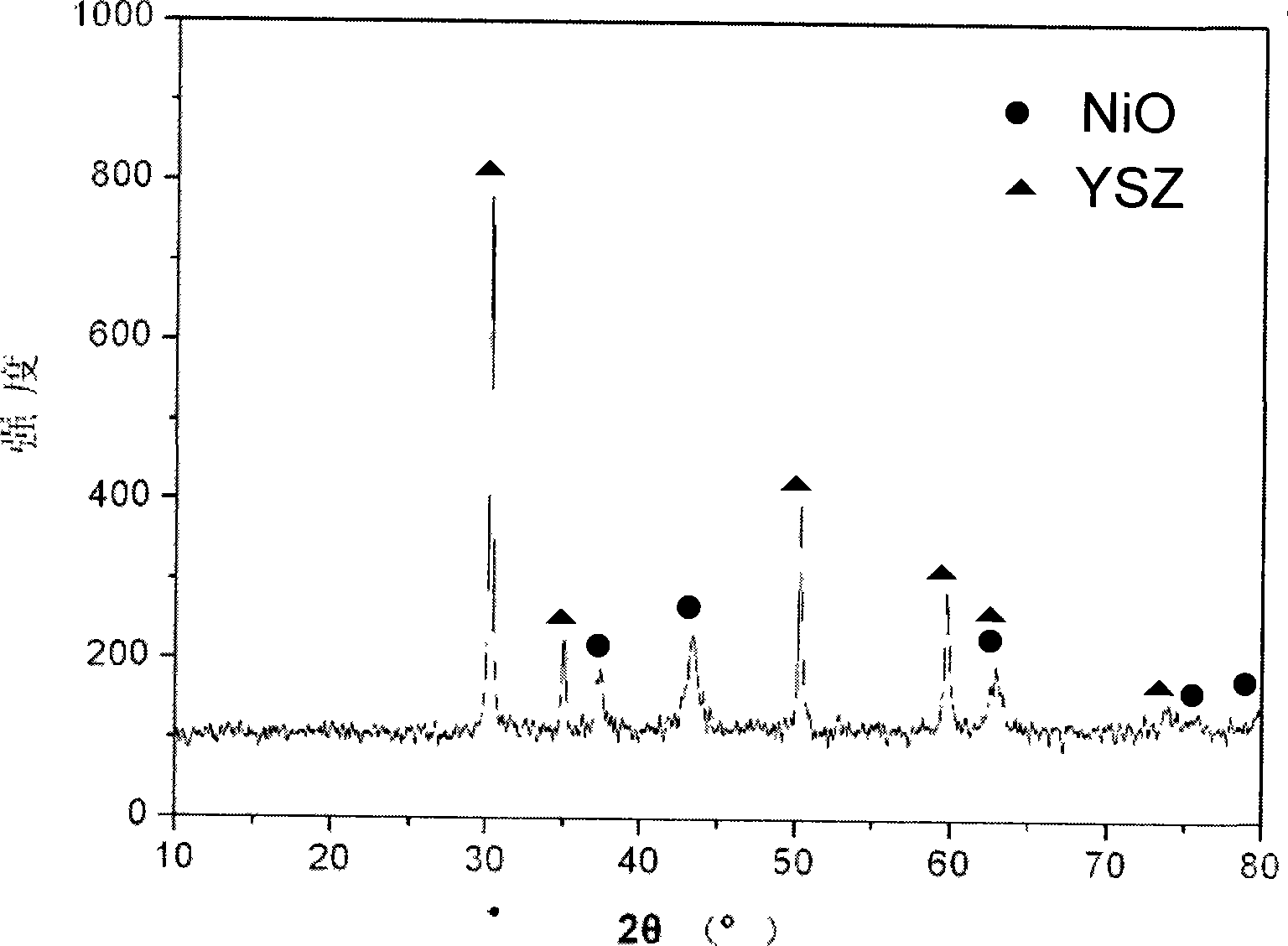

[0030] Example 2: In-situ synthesis of NiO-YSZ powder by ultrasonic-assisted ammonia precipitation

[0031] Weigh 36.35g Ni(NO 3 ) 2 ·6H 2 O, prepare 0.5mol / L nickel nitrate solution with deionized water, then add 6.00g YSZ powder (Tosoh 8YSZ in Japan) to the nickel nitrate solution, under the stirring condition of 25 ℃ water bath and ultrasonic vibration and 600r / min Ammonia water was added dropwise to the mixture to adjust the pH value of the solution to 8.0, resulting in a light green precipitate. After the addition of ammonia water, adjust the temperature of the water bath to 70°C, let the precipitate continue to mature for 2 hours, then filter, wash, and dry the matured precipitate at 110°C, and finally put it in a muffle furnace and roast at 400°C for 2 hours to obtain 12.86 g NiO-YSZ powder. The mass percent content of NiO in the powder is about 53%. The X-ray diffraction pattern (XRD) and the scanning electron microscope (SEM) photograph of gained NiO-YSZ powder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com