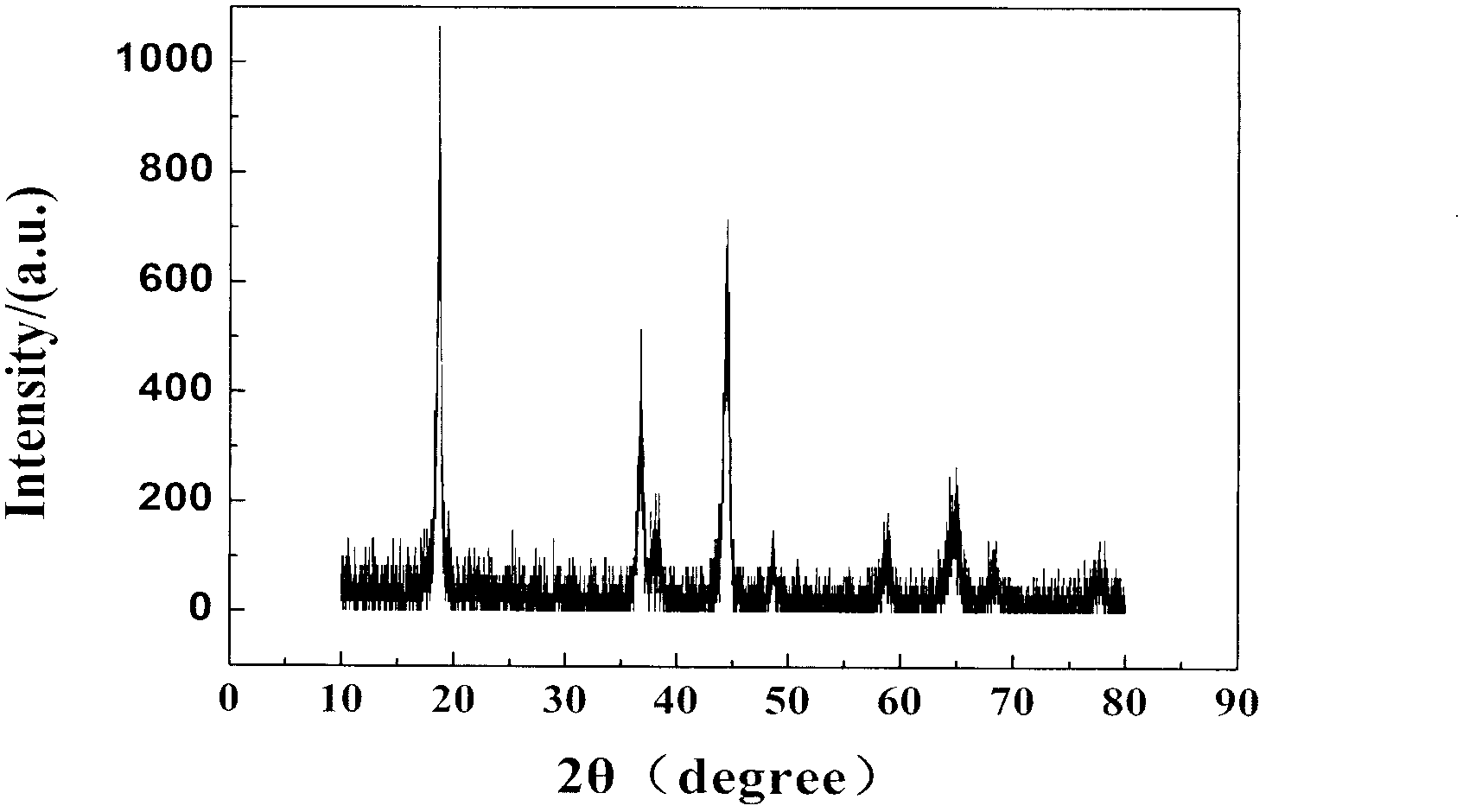

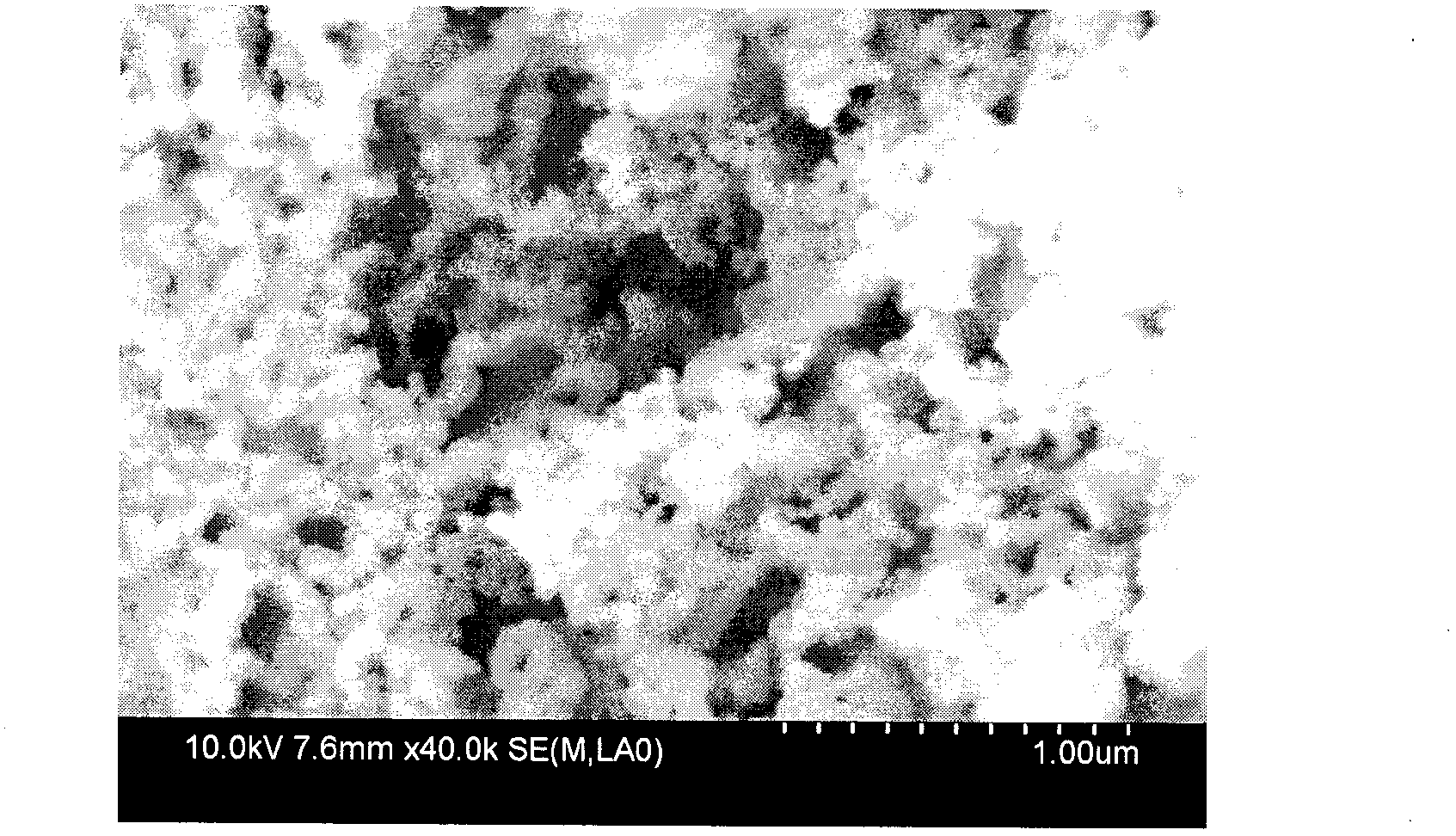

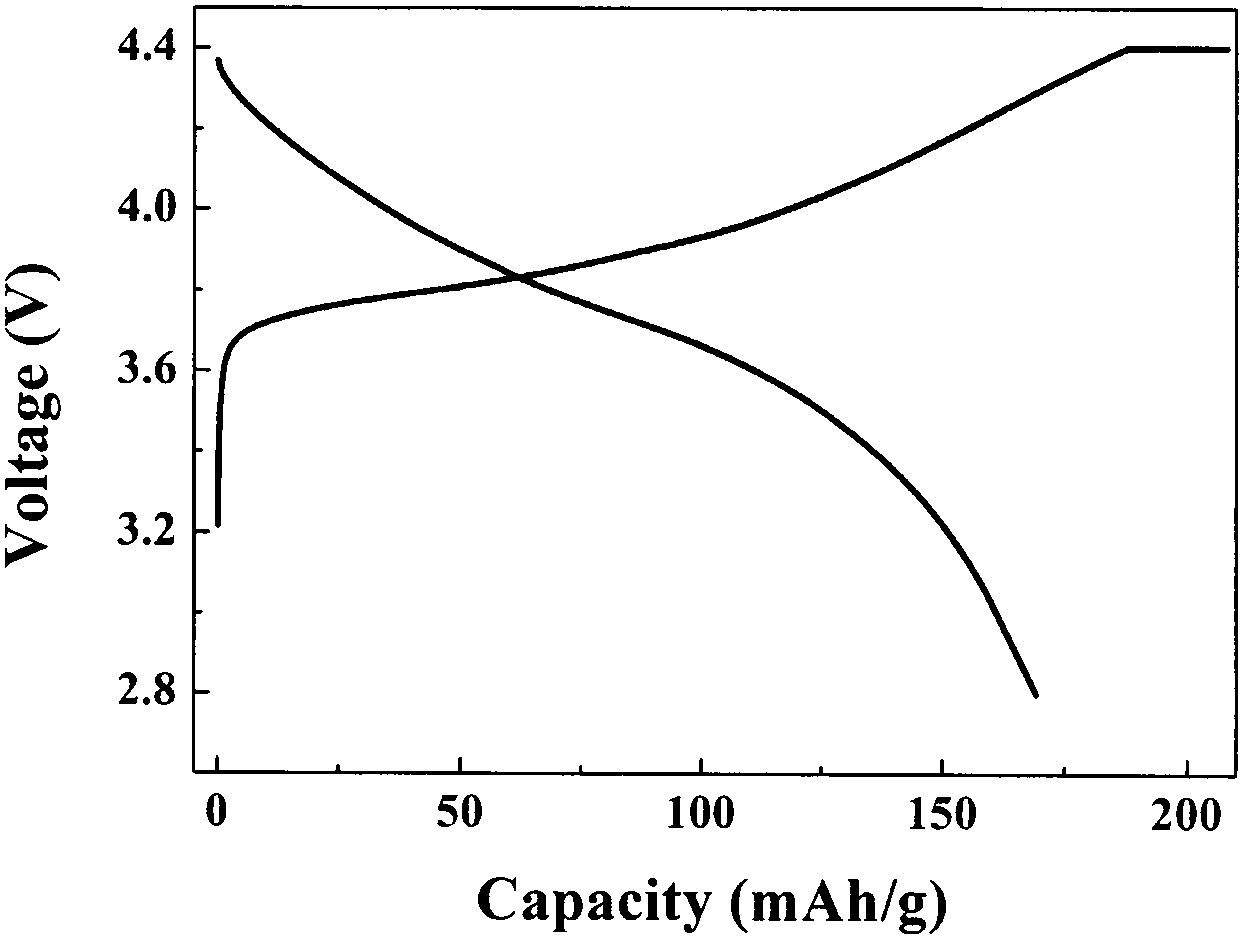

Preparation method for nickel cobalt lithium manganate LiNixConMn1-x-yO2 of anode material of lithium ion battery

A technology of nickel-cobalt lithium manganese oxide and lithium-ion batteries, which is applied in the field of new energy materials, can solve the problems of complex sol preparation process, irregular shape, and high calcination temperature, and achieve excellent electrochemical performance and overcome uneven shape. The effect of regularity and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of lithium ion battery cathode material nickel cobalt lithium manganese oxide LiNi x co y mn 1-x-y o 2 The preparation method, the method steps are as follows:

[0036] (1) Sol preparation;

[0037] Dissolve lithium nitrate, nickel nitrate, cobalt nitrate, and manganese acetate in a molar ratio of 1.05:0.4:0.4:0.2 in deionized water, and then add complexing agent polyacrylic acid (relative molecular mass: 800-1000, solid content: 30%) , configured so that the total concentration of cations (Li+Ni+Co+Mn) is 0.6mol / L, the molar ratio of polyacrylic acid monomer content to cations is 1, mix well, and heat and stir the mixed solution in a water bath at 60°C for 2h to obtain Transparent red sol.

[0038] (2) Gel preparation

[0039] ① Evaporate and concentrate the sol in a constant temperature water bath at 90°C until a solid wet gel is formed;

[0040]②Put the solid wet gel in a blast drying oven at 100°C and dry for 10 hours to obtain a solid xerogel. After t...

Embodiment 2

[0046] A kind of lithium ion battery cathode material nickel cobalt lithium manganese oxide LiNi x co y mn 1-x-y o 2 The preparation method, the method steps are as follows:

[0047] (1) Preparation of sol: dissolve lithium nitrate, nickel nitrate, cobalt nitrate, and manganese acetate in deionized water at a molar ratio of 1.05:0.33:0.33:0.33, then add complexing agent polyacrylic acid (relative molecular mass is 800-1000, The solid content is 30%), configured so that the total concentration of cations (Li+Ni+Co+Mn) is 0.8mol / L, and the molar ratio of polyacrylic acid monomer content to cations is 0.75, mix evenly, and put the mixed solution in a water bath at 60°C Under the condition of heating and stirring for 2h, a transparent red sol was obtained.

[0048] (2) Gel preparation

[0049] ① Evaporate and concentrate the sol in a constant temperature water bath at 90°C until a solid wet gel is formed;

[0050] ②Put the solid wet gel in an air-blast drying oven at 100°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com