Preparation for high-performance solid oxidate electrolytic cell perovskite oxygen electrode powder

A solid oxide and oxygen electrode technology, applied in electrolysis process, electrolysis components, etc., can solve the problems of inaccurate product stoichiometric ratio, complex condition control, metal ion segregation, etc., and achieve accurate stoichiometric ratio and high product specific surface area , active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

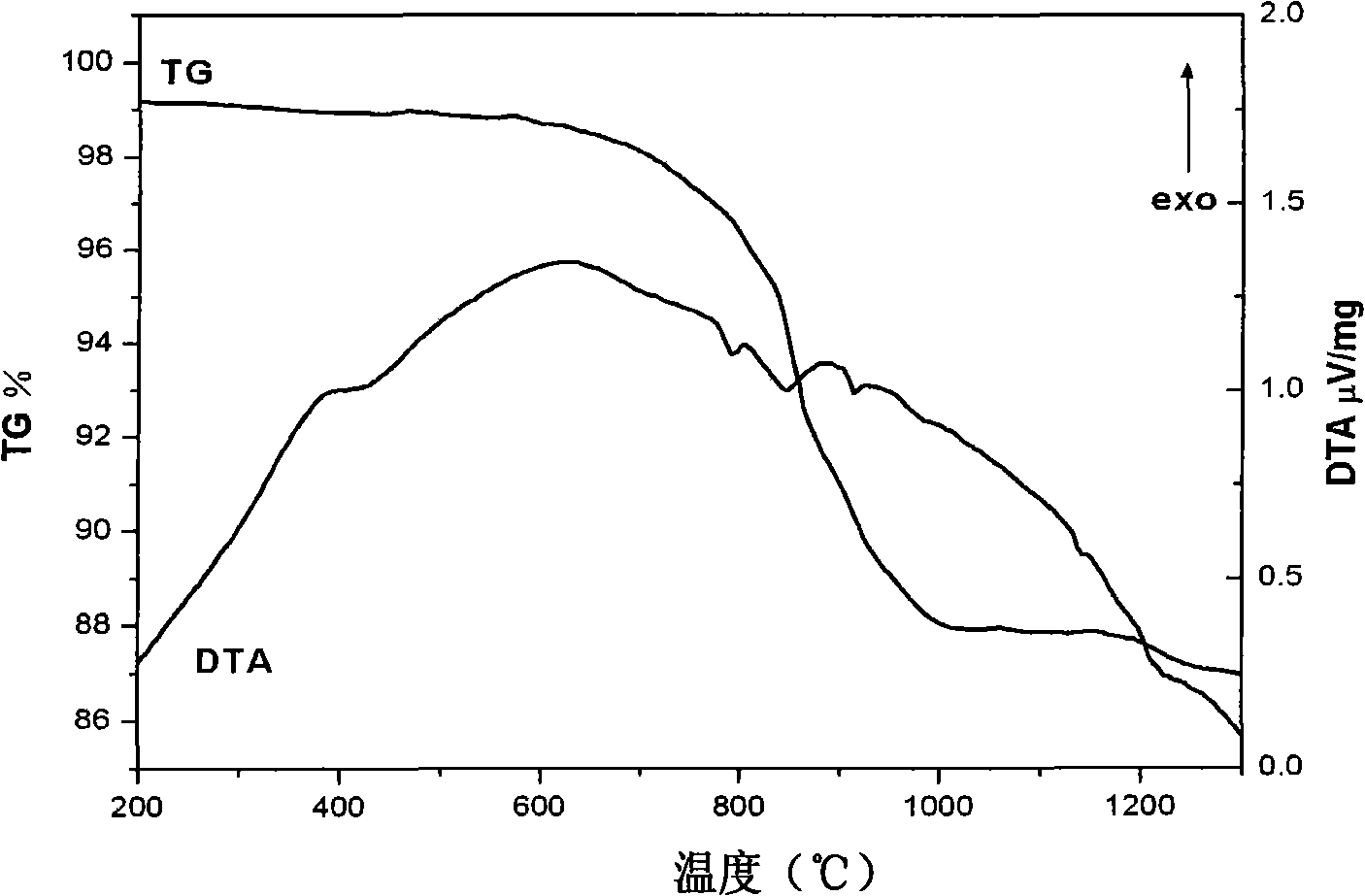

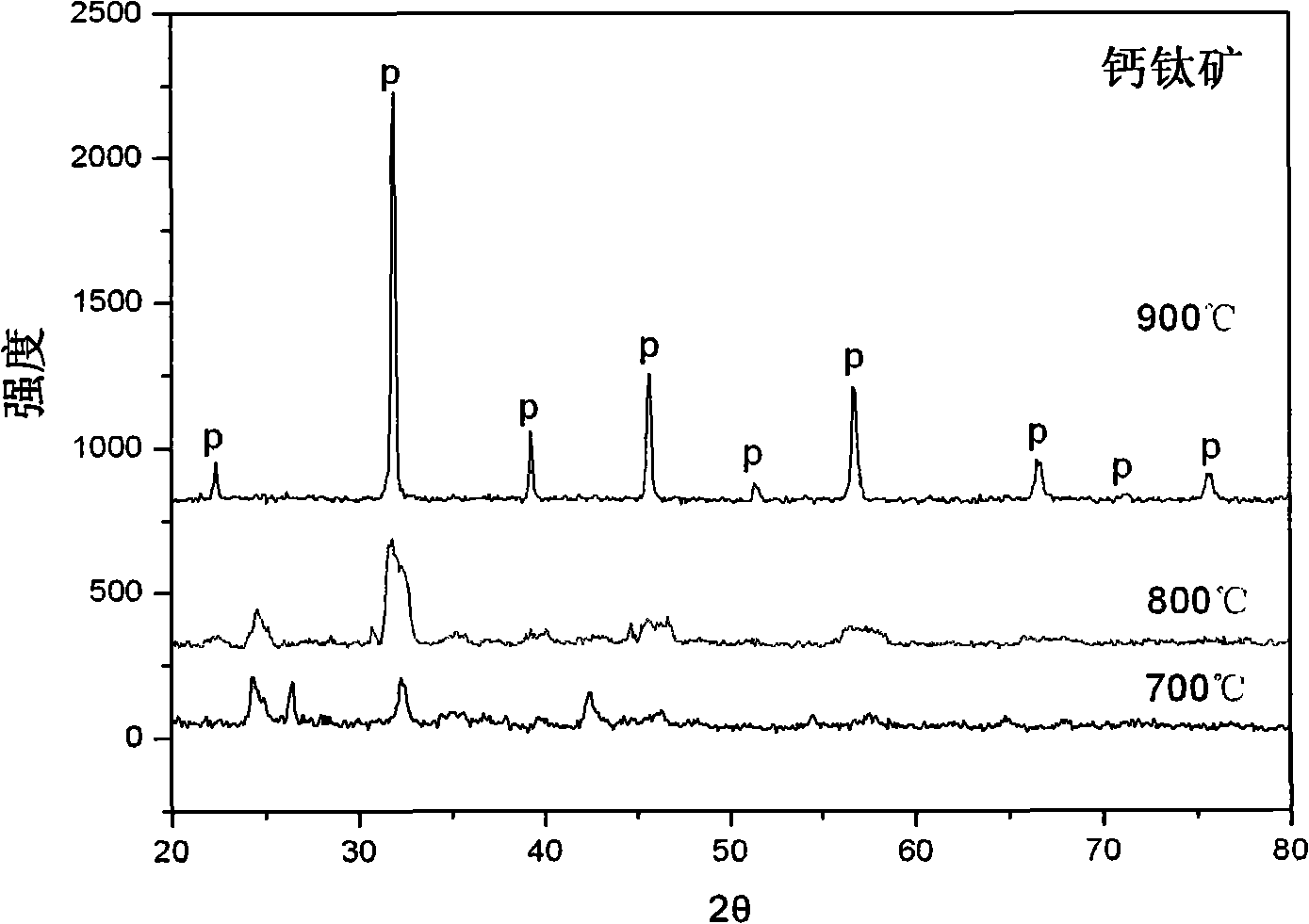

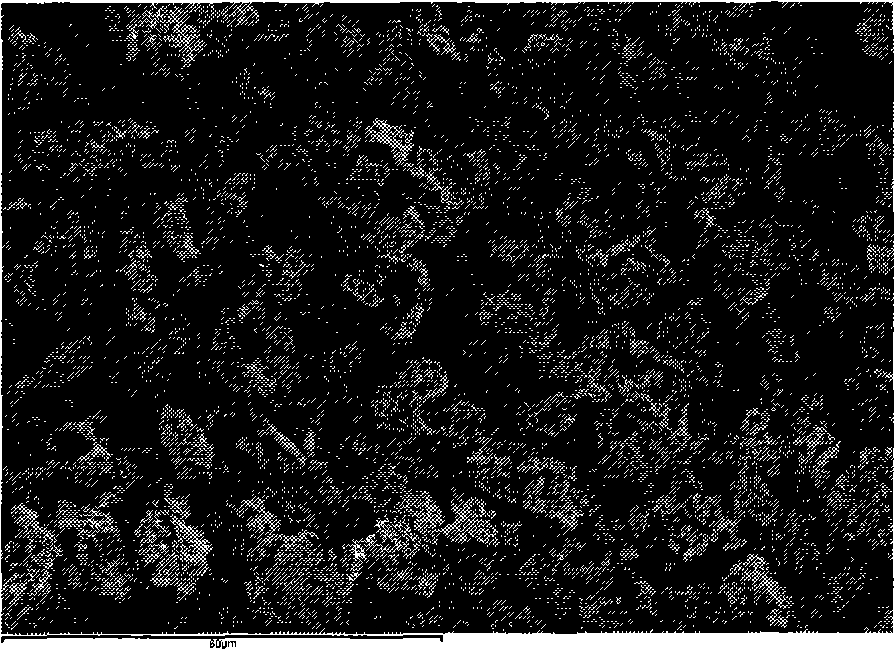

[0024] Example 1: Nanoscale perovskite oxygen electrode material Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 (BSCF) powder preparation

[0025] Preparation of Ba(NO 3 ) 2 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 , Fe(NO 3 ) 3 The solution and reagents were of analytical grade, dissolved in deionized water, and constant volume in a volumetric flask; Sr(NO 3 ) 2 , Co(NO 3 ) 2 and Fe(NO 3 ) 3 The concentration was accurately calibrated by EDTA complexometric titration, Ba(NO 3 ) 2 The concentration was calibrated by gravimetric method. Accurately pipette Ba(NO 3 ) 2 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 , Fe(NO 3 ) 3 solution, mix and stir evenly; take citric acid according to the ratio of citric acid: metal ion is 2: 1, add appropriate amount of water to dissolve and stir, add in the mixed solution of metal ion, stir and mix evenly in 80 ℃ water bath; according to ammonium nitrate: citric acid is Add solid ammonium nitrate at a ratio of 2:1, stir and add the mixed solution, and stir in a wa...

example 2

[0030] Example 2: Perovskite Oxygen Electrode Material La 0.5 Sr 0.5 co 0.8 Fe 0.2 (LSCF) powder preparation

[0031] Preparation of Sr(NO 3 ) 2 , La(NO 3 ) 3 , Co(NO 3 ) 2 , Fe(NO 3 ) 3 The solutions and reagents were all of analytical grade and dissolved in deionized water; high-purity La was dissolved in nitric acid 2 o 3 The method of preparing La(NO 3 ) 3Solution, constant volume in volumetric flask; La(NO 3 ) 3 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 and Fe(NO 3 ) 3 The concentration of the concentration is accurately calibrated by the EDTA complexometric titration method; the La(NO 3 ) 3 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 , Fe(NO 3 ) 3 solution, mix and stir evenly; take citric acid according to the ratio of citric acid: metal ion is 2: 1, add appropriate amount of water to dissolve and stir, add in the mixed solution of metal ion, stir and mix evenly in 80 ℃ water bath; according to ammonium nitrate: citric acid is Add solid ammonium nitrate at a ratio of 2:...

example 3

[0032] Example 3: Perovskite Oxygen Electrode Material Pr 0.5 Sr 0.5 co 0.8 Fe 0.2 (PSCF) powder preparation

[0033] Preparation of Sr(NO 3 ) 2 , Pr(NO 3 ) 4 , Co(NO 3 ) 2 , Fe(NO 3 ) 3 The solution and reagents were of analytical grade, dissolved in deionized water; constant volume in a volumetric flask; Pr(NO 3 ) 4 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 and Fe(NO 3 ) 3 The concentration of the concentration is accurately calibrated by the EDTA complexometric titration method; the Pr(NO 3 ) 4 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 , Fe(NO 3 ) 3 solution, mix and stir evenly; take citric acid according to the ratio of citric acid: metal ion is 2: 1, add appropriate amount of water to dissolve and stir, add in the mixed solution of metal ion, stir and mix evenly in 80 ℃ water bath; according to ammonium nitrate: citric acid is Add solid ammonium nitrate at a ratio of 2:1, stir and add the mixed solution, and stir in a water bath at 80°C for about an hour; transfer the solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com